Plastic bottle vacuum leak detection and leak detection ridding mechanism

A technology for removing mechanisms and plastic bottles, applied in sorting and other directions, can solve problems such as affecting the accuracy of leak detection, liquid leakage, and complex structure and action of the rejecting device, so as to improve the accuracy of leak detection and simplify the structure of the rejecting device. and action effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments.

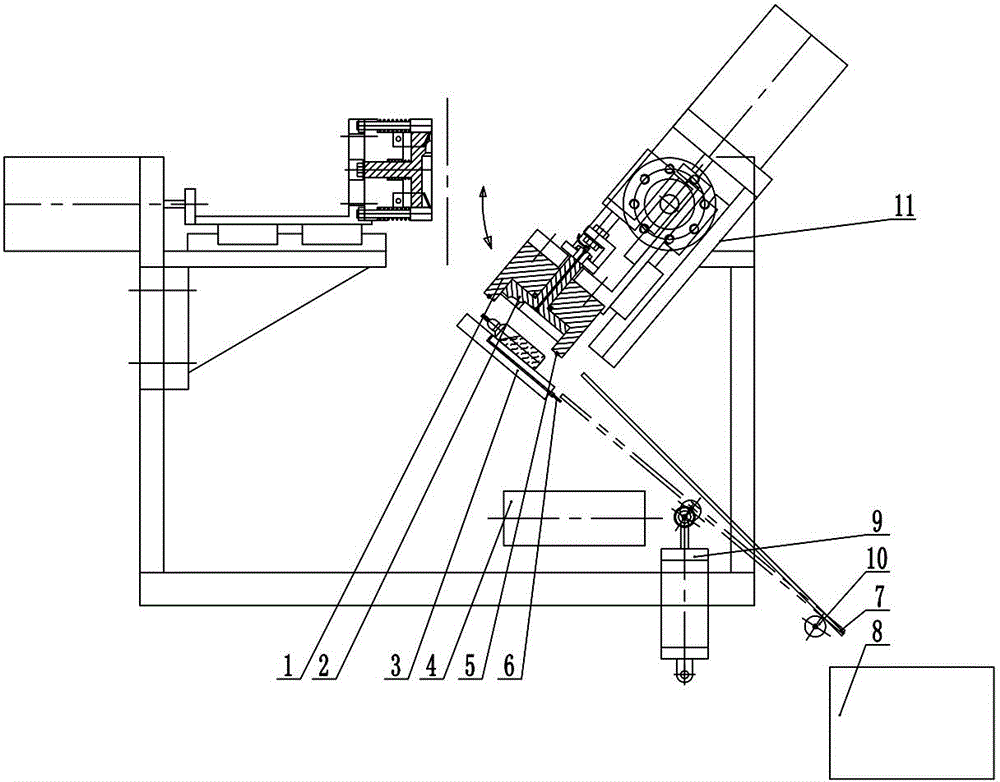

[0020] refer to figure 1 , The plastic bottle vacuum leak detection and leak detection rejection mechanism of the present invention includes a vacuum leak detection mold device 1 and a vacuum cabin floor 3 . In this embodiment, the vacuum cabin bottom plate 3 is inclined relative to the horizontal direction, and the inclination angle of the vacuum cabin bottom plate 3 relative to the horizontal direction is selected according to the shape of the leak detection container, the amount of liquid medicine, and ensuring that the liquid in the plastic bottle does not reach the shoulder neck. the angle of inclination. The vacuum leak detection mold device 1 is the half mold of the punching die, the vacuum leak detection mold device 1 is connected to the rotating shaft 11, and the vacuum leak detection mold device 1 is driven to reciprocate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com