Mandrel screw-on machine pre-screwing and auxiliary machine device

A pre-twist and mandrel technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of large-diameter mandrels that cannot be screwed, high equipment costs, mandrel tripping, etc. Performance and representativeness, high degree of automation, and accurate screwing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The working principle of each part of the present invention is as follows:

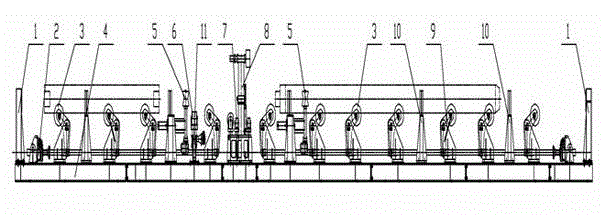

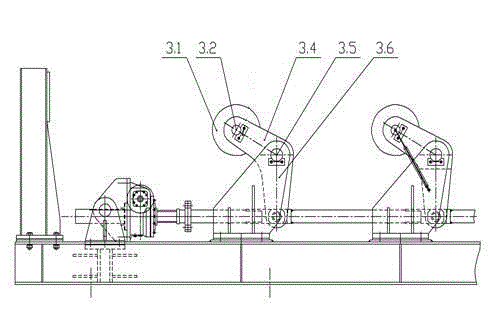

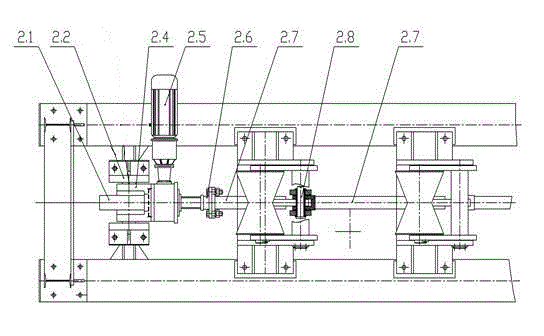

[0028] A pre-twisting and auxiliary device for a mandrel screwing machine, which mainly includes: a pull rod driving mechanism, a support roller mechanism, a clamping transfer mechanism, a rotating support mechanism, a double roller mechanism, a rotating pre-twisting mechanism, a material retaining frame and a base . The whole device is mainly divided into three parts: inlet mechanism assembly, pre-twist mechanism assembly and outlet mechanism assembly. All parts are fixed on the base. Its function is to automatically complete the pre-tightening of the threads of the working section, extension section and clamping section of the mandrel, and cooperate with the screwing host to screw and loosen the work. The inlet mechanism assembly is responsible for moving the extension section of the mandrel into the screwing rotation position and performing center adjustment and rotation support, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com