Cooling device and method for butt welding of coiled tubing

A cooling device and coiled tube technology, applied in the field of material thermal processing, can solve problems such as performance degradation of welded joints, grain growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing.

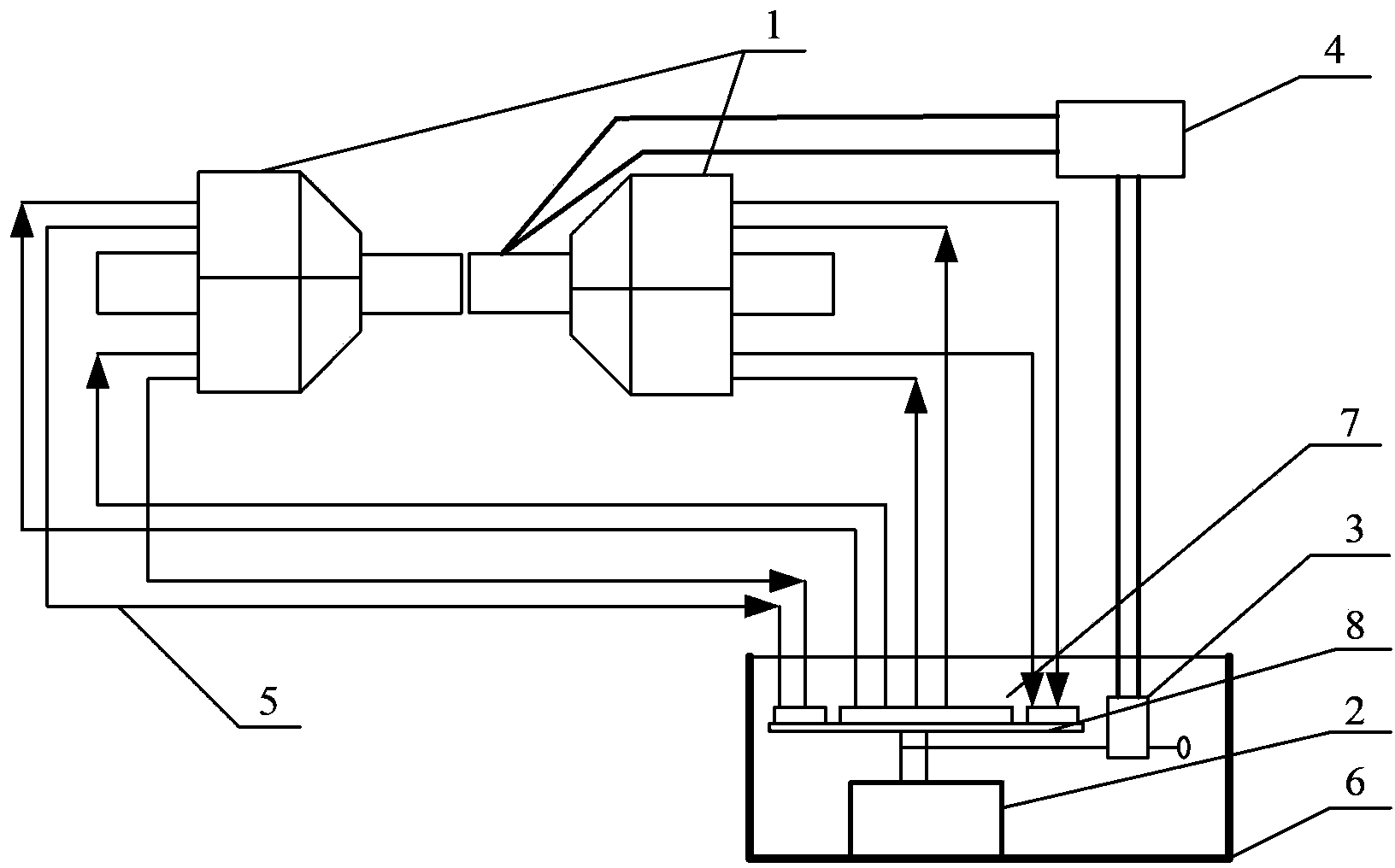

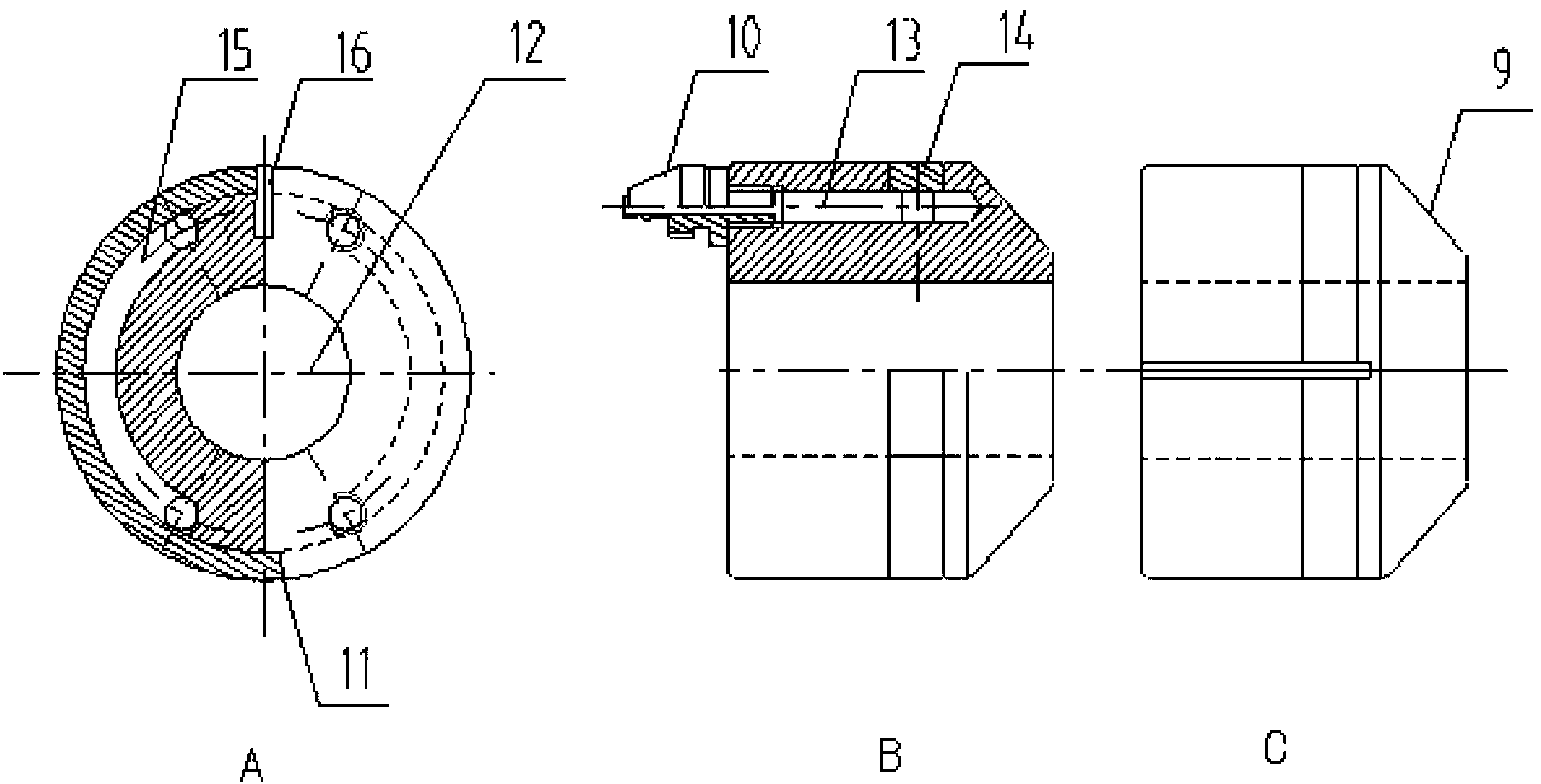

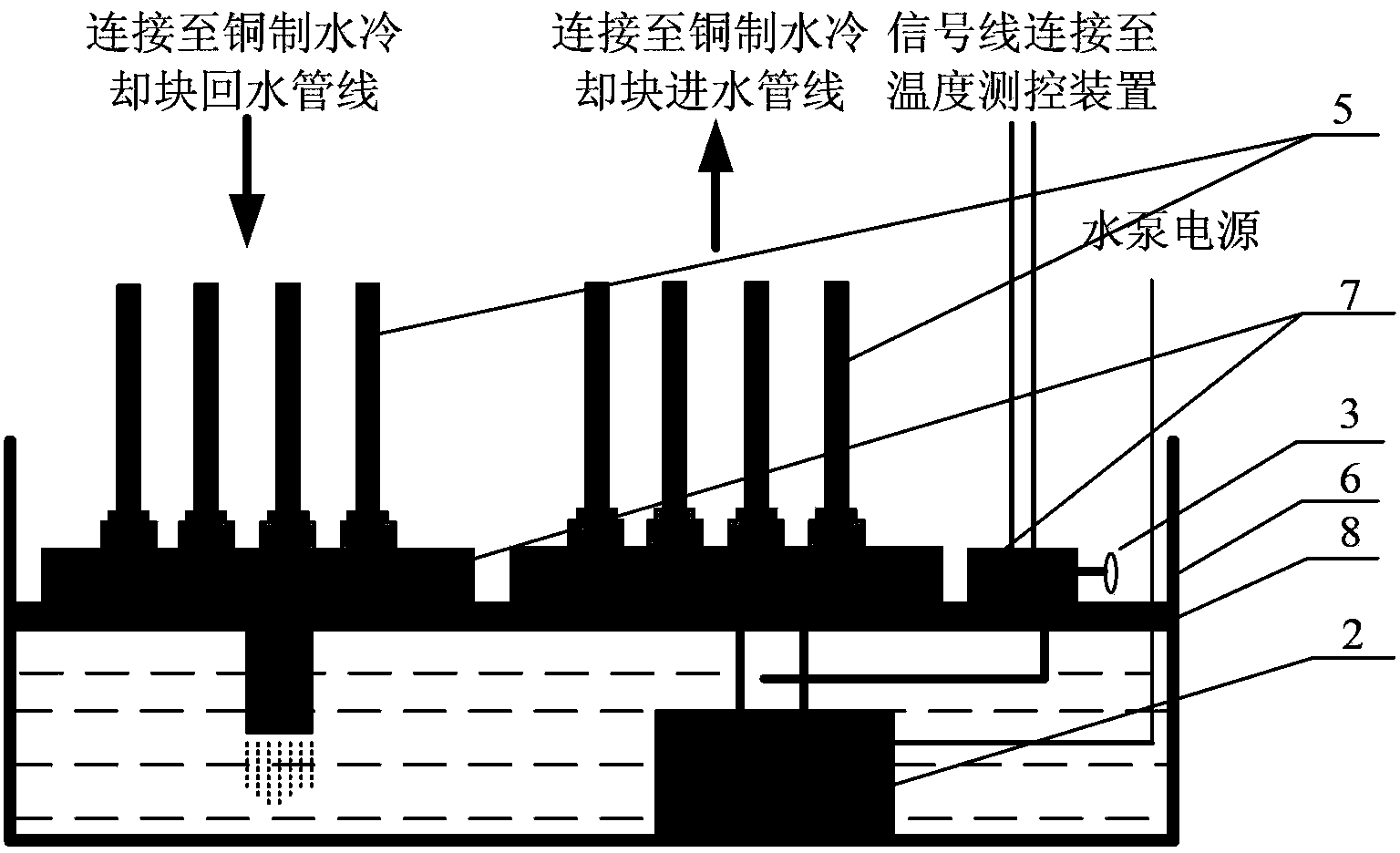

[0023] refer to figure 1 : A cooling device for coiled pipe butt welding, comprising a water pump 2, the water pump 2 is placed in a water supply and return device 6 filled with sufficient water, the water outlet of the water pump is connected to the five-way joint 7 through a pipeline, and a flow rate is installed on the water pump outlet pipeline Adjusting device 3, the flow regulating device 3 is connected with the temperature measurement and control device 4, through manual adjustment and temperature measurement and control device 4 to control the flow adjustment, adjust the opening and closing of the gate valve to change the flow rate of the water pump; the five-way joint 7 is fixed On the partition 8; the four joints on the upper part of the five-way joint 7 are respectively connected to the four cooling block water inlet pipelines 5 and connected to two opposite cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com