Method for preventing wolfram carbine decomposition and sinking in argon arc weld deposit process on base steel body

A tungsten carbide and steel matrix technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of easy decomposition and sinking of tungsten carbide particles, and achieve the advantages of reducing temperature, short residence time and reducing thermal effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Specific implementation mode one: this implementation mode consists of the following steps:

[0010] Step 1, using the oxygen-acetylene flame spraying method to evenly spray the nickel-chromium-borosilicate self-fluxing alloy powder onto the surface of the workpiece to be surfacing;

[0011] Step 2, sending tungsten carbide particles into the part of the molten pool that is not heated by arc burning.

[0012] The method of this embodiment is mainly used in the field of argon arc surfacing. The invention patent with the publication number of CN101220475 discloses a method for manufacturing surface composite materials. In the manufacturing process, the method described in this embodiment can be used to spray a Layer alloy powder, and send carbide particles to the tail of the molten pool, which can effectively prevent the decomposition and bottom sinking of tungsten carbide particles.

specific Embodiment approach 2

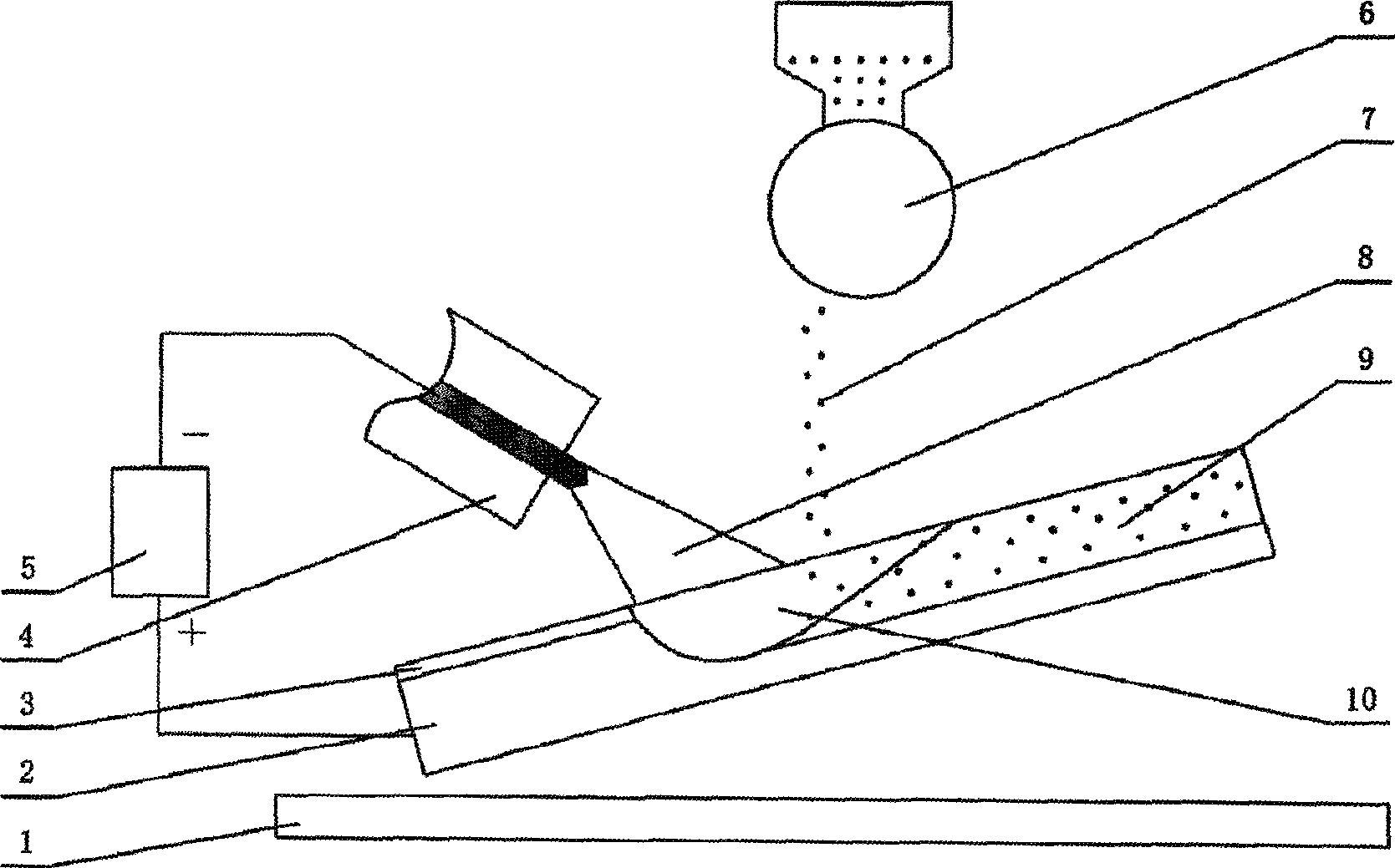

[0013] Specific implementation mode two: see figure 1 , this embodiment is an example of applying the method described in Embodiment 1 to the overlay welding method for high wear-resistant and impact-resistant tungsten carbide composite plates:

[0014] Step 1, using Q235 steel as the substrate 2, degreasing and dewatering the surface to be surfacing;

[0015] Step 2: Perform sandblasting on the surface to be surfacing of the substrate 2, the sand used for sandblasting is 16-40 mesh brown corundum sand, and the sandblasting pressure is 0.4-0.8MPa;

[0016] Step 3: Fix the substrate 2 on the worktable 1, the worktable 1 is at an angle of 10°-20° to the horizontal plane, and spray the nickel-chromium borosilicate self-fluxing alloy powder on the substrate 2 evenly by using the oxygen-acetylene flame spraying method On the surface to be surfacing, a sprayed layer 3 is obtained, and the thickness of the sprayed layer 3 is 0.1-1.0 mm;

[0017] Step 4. The self-weight feeding devi...

specific Embodiment approach 3

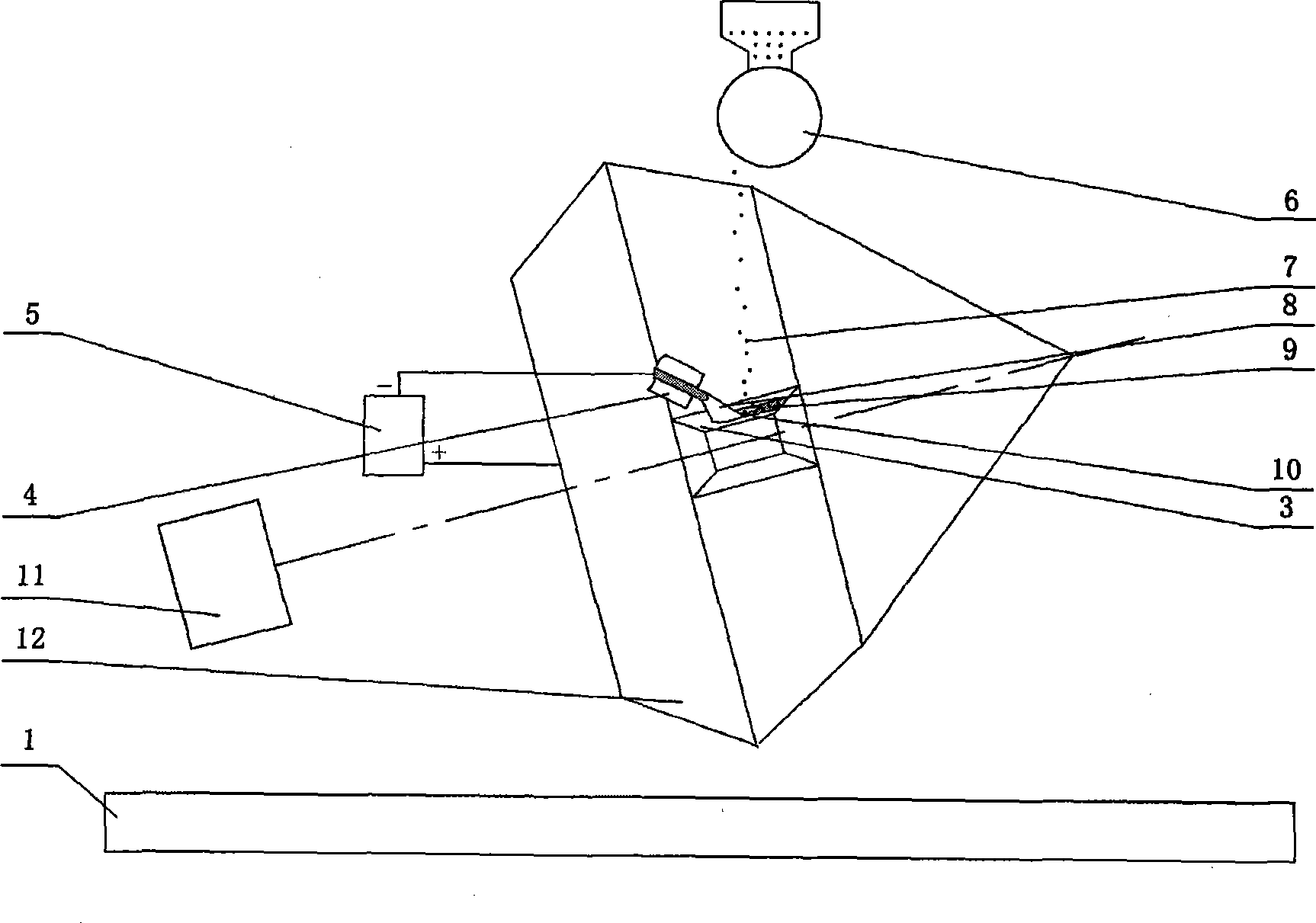

[0023] Specific implementation mode three: see figure 2 , this embodiment is an embodiment of applying the method described in Embodiment 1 to the surfacing method for steel toothed cone bits:

[0024] Step 1, degreasing and dewatering the surface of the steel tooth gear 12 to be surfacing;

[0025] Step 2: Perform sandblasting on the surface of the steel tooth gear 12 to be surfacing, the sand used for sandblasting is 16-40 mesh brown corundum sand, and the sandblasting pressure is 0.4-0.8 MPa;

[0026] Step 3: Fix the steel-toothed gear 12 on the turntable 11, the rotation axis of the turntable 11 and the horizontal plane form an angle of 10° to 20°; use the oxygen-acetylene flame spraying method to evenly spray the nickel-chromium-borosilicate self-fluxing alloy powder To the surface of the steel teeth to be surfacing of the steel tooth gear 12, a sprayed layer 3 is obtained, and the thickness of the sprayed layer 3 is 0.1-1.0mm;

[0027] Step 4. The self-weight feeding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com