Pulse current auxiliary increment repair device and method

A pulse current and repair method technology, which is applied in metal extrusion, manufacturing tools, metal processing equipment, etc., can solve the problem of difficult incremental repair of tire molds, and achieve the goals of improving energy utilization, heating efficiency, and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

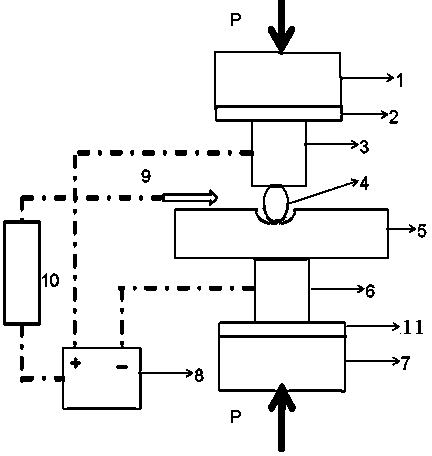

[0024] combined with figure 1 , figure 2 with image 3 , to further describe the present invention:

[0025] A pulse current assisted incremental repair device, including an upper indenter 1, an upper insulating pad 2, an upper electrode 3, a filler 4, a lower electrode 6, a lower indenter 7, a pulse power supply 8, an infrared temperature measuring device 9 and a PID control System 10 and lower insulating spacer 11; the filler 4 is placed in the missing part of the product 5 to be repaired, and the top of the filler 4 is connected to the upper pressure head 1 through the upper electrode 3 and the upper insulating spacer 2; in the product 5 to be repaired The bottom is connected to the lower pressure head 7 through the lower electrode 6 and the lower insulating spacer 11; the upper electrode 3 and the lower electrode 6 are respectively connected to the positive and negative poles of the pulse power supply 8; one side of the filler 4 is provided with an infrared Temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com