Tapered ceramic bottleneck green body forming device

A technology for forming devices and green bodies, which is applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as low efficiency, and achieve the effect of simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

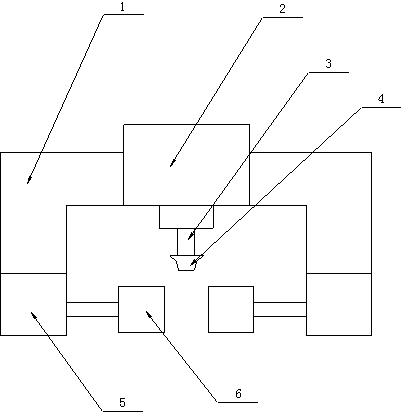

[0009] see figure 1 , the specific embodiment adopts the following technical scheme: it includes a U-shaped body forming device support 1, a low-speed rotating motor 2, a telescopic rod 3, a tapered grinding head 4, a telescopic pressing device 5, and a bottleneck mold groove 6. A low-speed rotating motor 2 is arranged in the middle of the support 1 of the U-shaped green body forming device, and a telescopic rod 3 is arranged at the lower end of the low-speed rotating motor 2, and a conical grinding head 4 is arranged at the lower end of the telescopic rod 3. The two ends of the telescopic compression device 5 are arranged, and the inner side of the telescopic compression device 5 is provided with a bottleneck mold groove 6.

[0010] The working principle of the present invention is as follows: Firstly, the mold grooves on both sides of the bottle neck are pressed together by a telescopic pressing device, and then the ceramic body is injected, and then the conical grinding hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com