Automatic stamping machine of print wheel

A bronzing machine and character wheel technology, applied in rotary printing presses, printing presses, gold powder printing and other directions, can solve the problems of affecting workers' health, high labor intensity, toxic ink, etc., and achieve high work efficiency, high hot stamping accuracy, automatic The effect of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

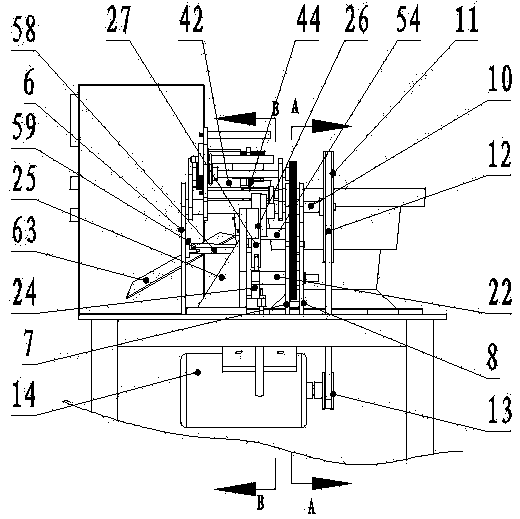

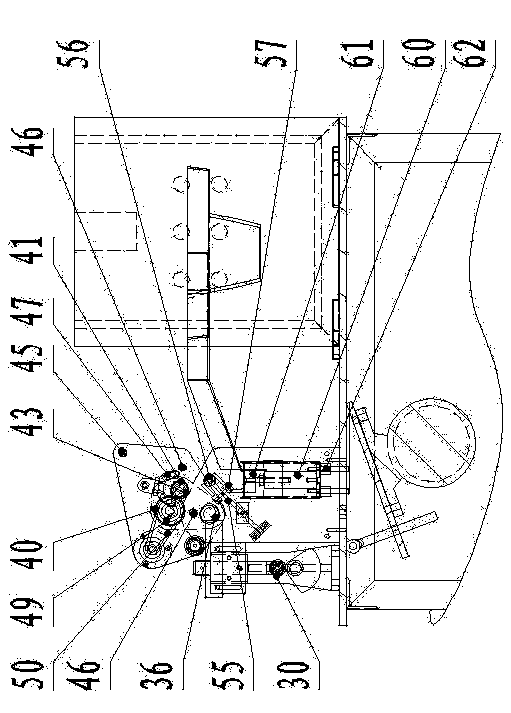

[0015] The present invention will be further described below with reference to the accompanying drawings and embodiments.

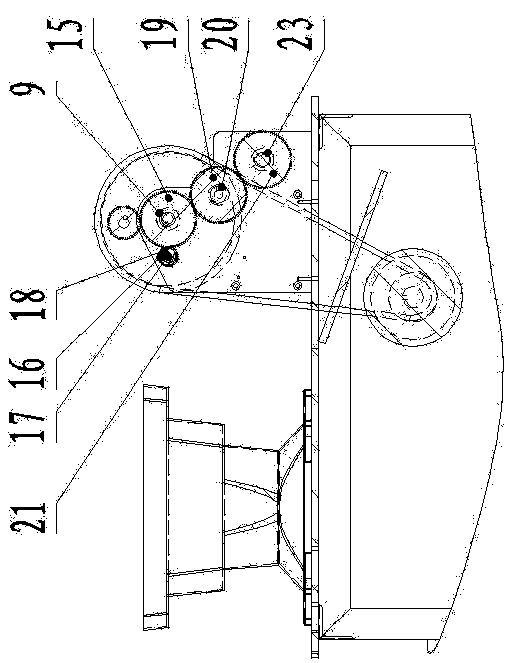

[0016] As shown in the figure, the left main shaft plate 6 is installed on the front left side of the base 1, the main shaft right plate A 7 is installed on the right side of the left main shaft plate 6, and the main shaft right plate B is installed on the right side of the main shaft right plate A 7 8. The left main shaft plate 6, the main main shaft right plate A 7, and the main main shaft right plate B 8 are fitted with the main shaft bearing 9 with the drive shaft 10. The right end of the active shaft 10 extends out of the main shaft right plate B 8 and is equipped with a large V The large V-shaped pulley 11 is connected with the motor wheel 13 on the main motor 14 installed in the base 1 by the V-shaped belt 12;

[0017] The drive shaft 10 between the main shaft right plate A 7 and the main shaft right plate B 8 is equipped with a driving gear 15, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap