Double-pool fermentation biogas tank with heater

A technology for fermenting biogas and heaters, which is applied in the field of biogas tanks, can solve problems such as affecting use, and achieve the effects of large gas production, small volume and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following is a further description of the new household model with reference to the drawings.

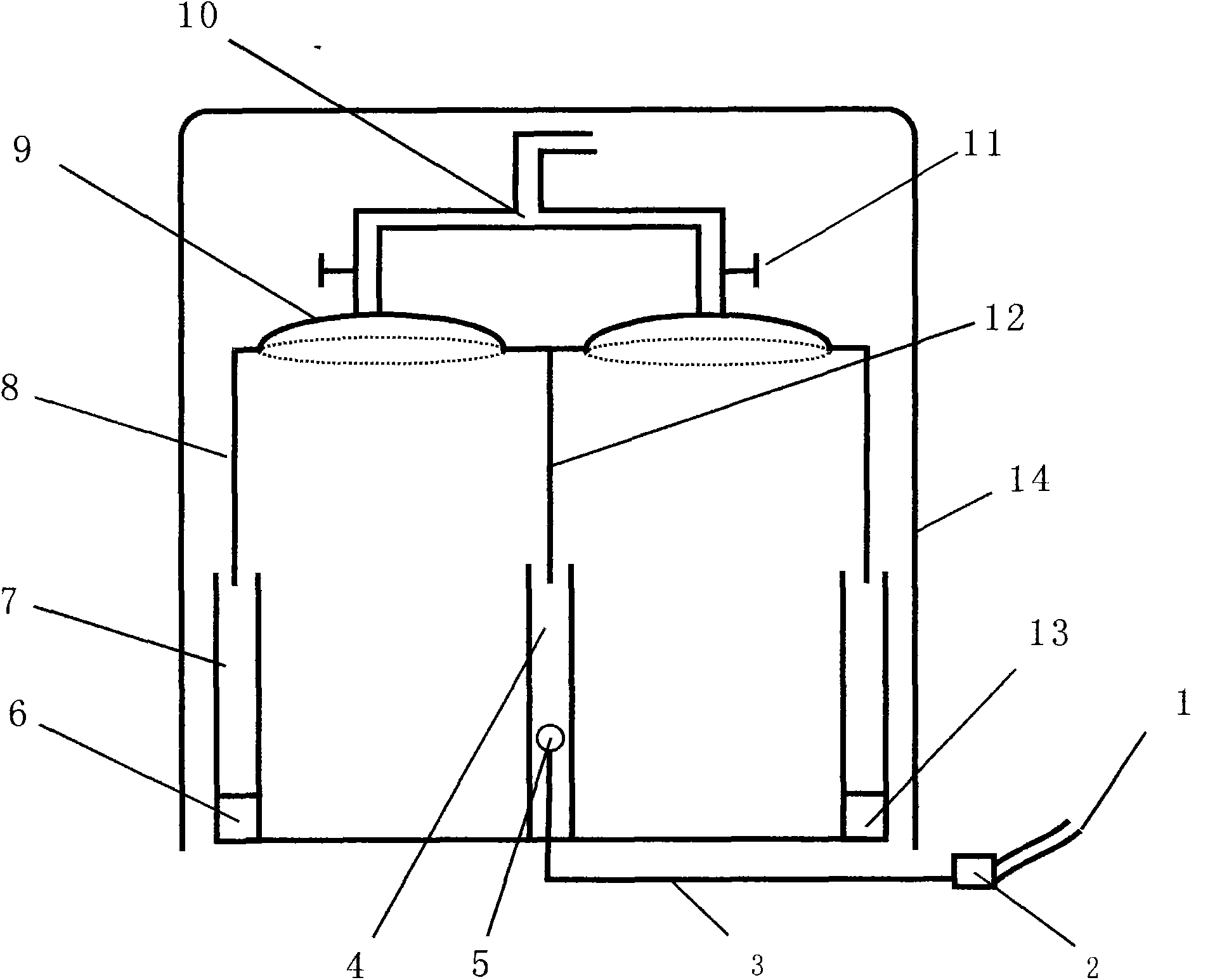

[0014] As shown in the figure: a dual-cell fermentation biogas tank with a heater, which is composed of a biogas tank, a thermostat 2, a heater 5 and a plastic cover 13. The feature is that the biogas tank is composed of a tank body and a floating cover. There is a box clamping wall 4 in the middle of the box. The box clamping wall 4 divides the fermentation chamber in the box into two. There is also a floating cover clamping cover wall 12 in the middle of the floating cover to divide the air storage chamber under the floating cover. There are two heaters 5 arranged at the lower part of the box wall 4, and connected to the thermostat 2 and the external power supply 1 through wires 3, and the plastic cover 13 is covered outside the biogas box.

[0015] The box body wall 4 and box body wall 7 are double-layered with sealed water in the middle, and communicate with each other. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com