Reinforcement cage main reinforcement connector connection structure and integral hoisting construction method

A technology of joint connection and steel cage, which is applied in the direction of structural elements, building components, building structures, etc., can solve the problems of low construction efficiency, large labor consumption, financial time, and difficult operation of a single hoisting, so as to reduce labor costs. And the effect of building construction machinery platform costs, reducing construction costs, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

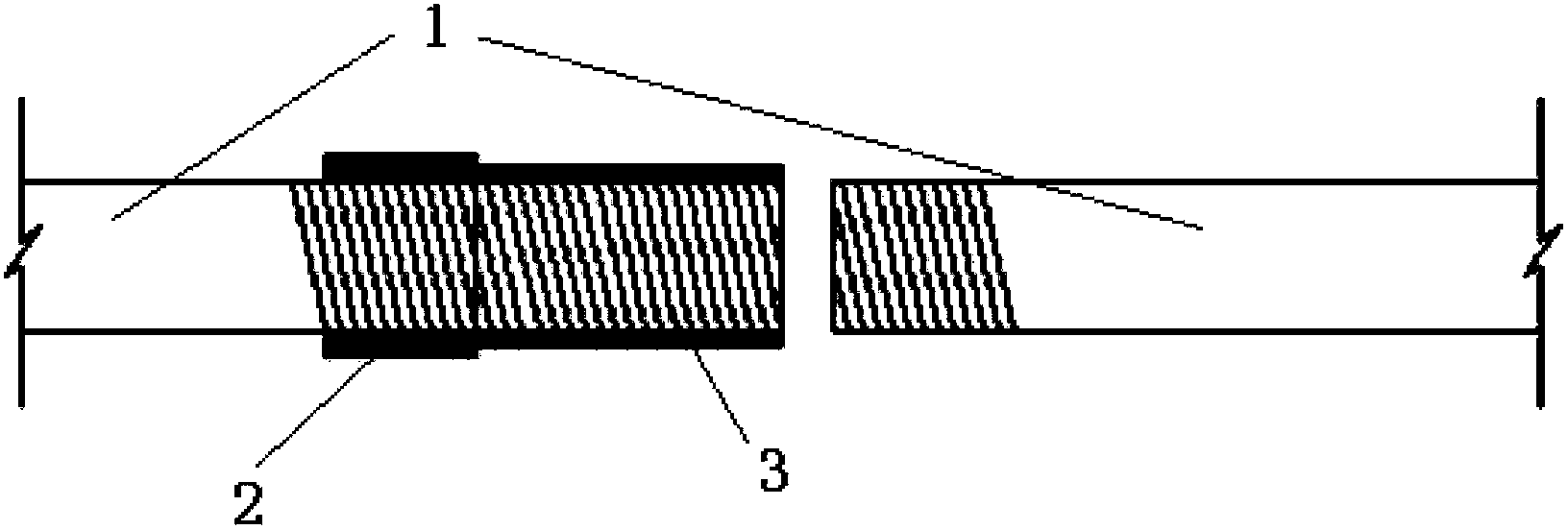

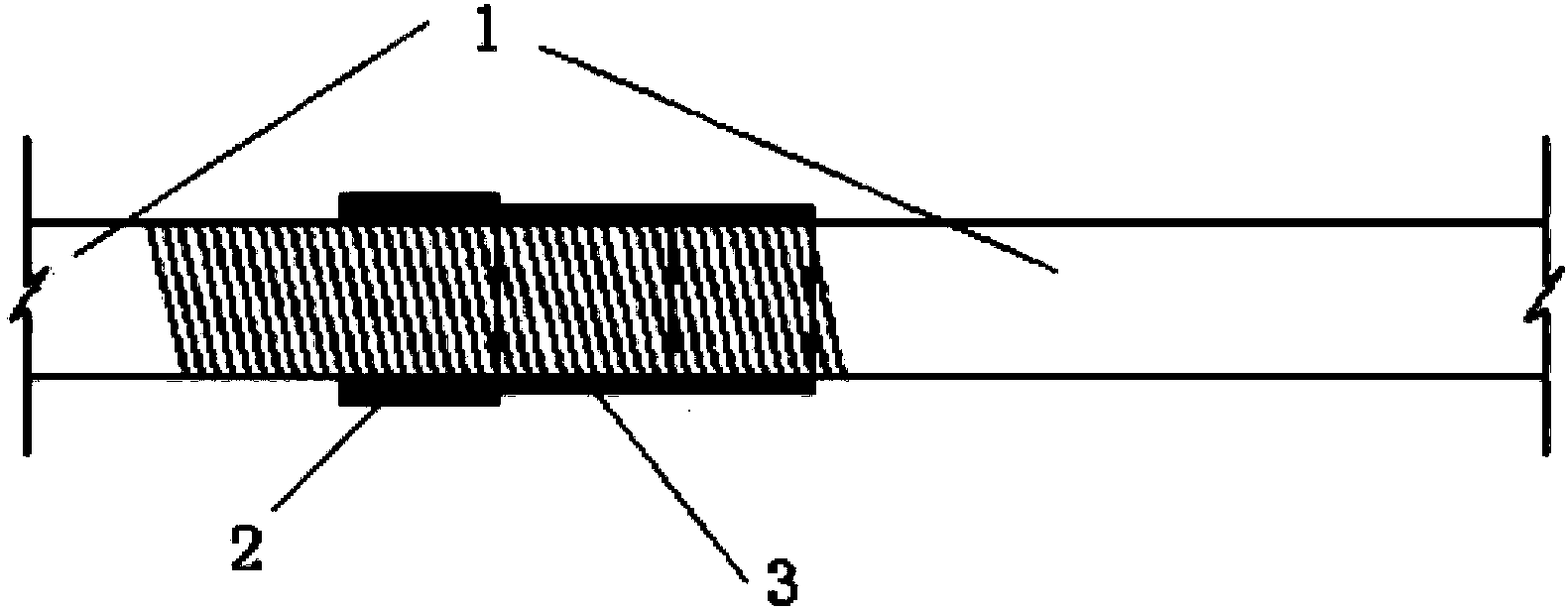

[0026] Such as figure 1 , figure 2 As shown, the connection structure of the main reinforcement joint of the reinforcement cage includes the sleeve 3, the lock nut 2, and the two butt joints 1 of the main reinforcement. + length of lock nut 2 + allowable deviation of the specification, recorded as a long wire joint; the wire length of the other main rib joint is half the length of the sleeve + allowable deviation of the specification, recorded as a short wire joint; the inner wall of the sleeve 3 has the same inward Screw threads, the ends of the two main rib joints 1 are all located in the sleeve 3, the lengths of the long wire joints and the short wire joints located in the inner parts of the sleeve 3 each account for 1 / 2, and then tighten the lock nut 2.

[0027] When hoisting the reinforcement cage as a whole, the first step is to process the reinforcement cage. The reinforcement cage should be processed as a whole on the ground in the reinforcement processing plant or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com