Unidirectional water guiding brick, bi-directional water guiding brick and a ground floor decoration structure adopting same

A water-conducting brick, one-way technology, applied in the direction of floors, building structures, buildings, etc., can solve problems such as affecting mood, uncomfortable stepping on, and off-flavor of floor drains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

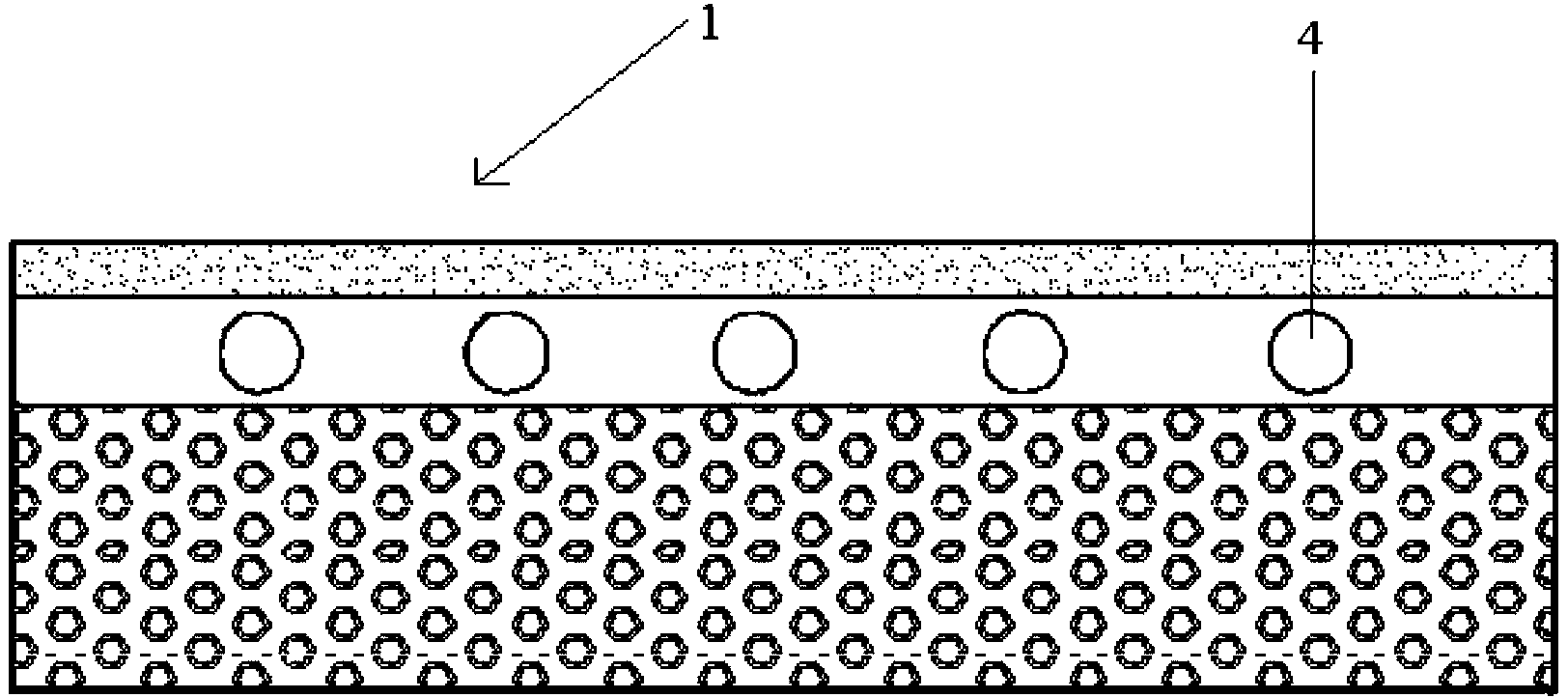

[0041] figure 1 It is a cross-sectional view of a cuboid-shaped one-way water-conducting brick 1 perpendicular to the direction of its water-conducting hole in the present invention, including an anti-seepage layer, a water-permeable layer arranged above the anti-seepage layer, and a water-permeable layer arranged above the water-permeable layer. Permeable surface. Wherein, the inside of the water-permeable layer is provided with a first water-guiding hole group, and the first water-guiding hole group is composed of five water-guiding holes 4 penetrating through the opposite sides of the water-permeable layer. The anti-seepage layers are parallel, and the five water guide holes are parallel to each other and have equal spacing.

[0042] In this embodiment, the water-permeable surface layer is a porous structure, and the porosity of the porous structure is 25%. In other embodiments, the porosity of the water-permeable surface layer can also be 15%, 30%, 35%, etc. as long as I...

Embodiment 2

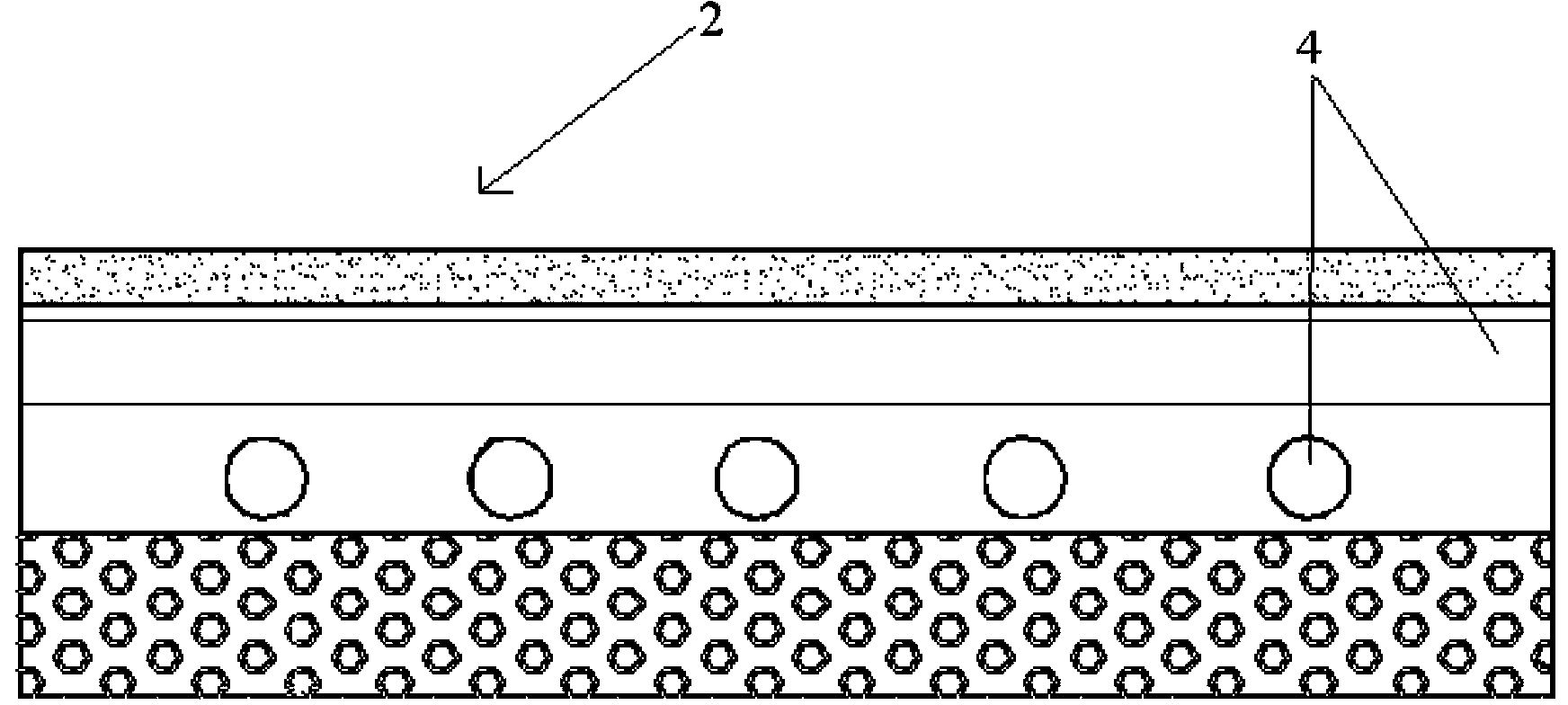

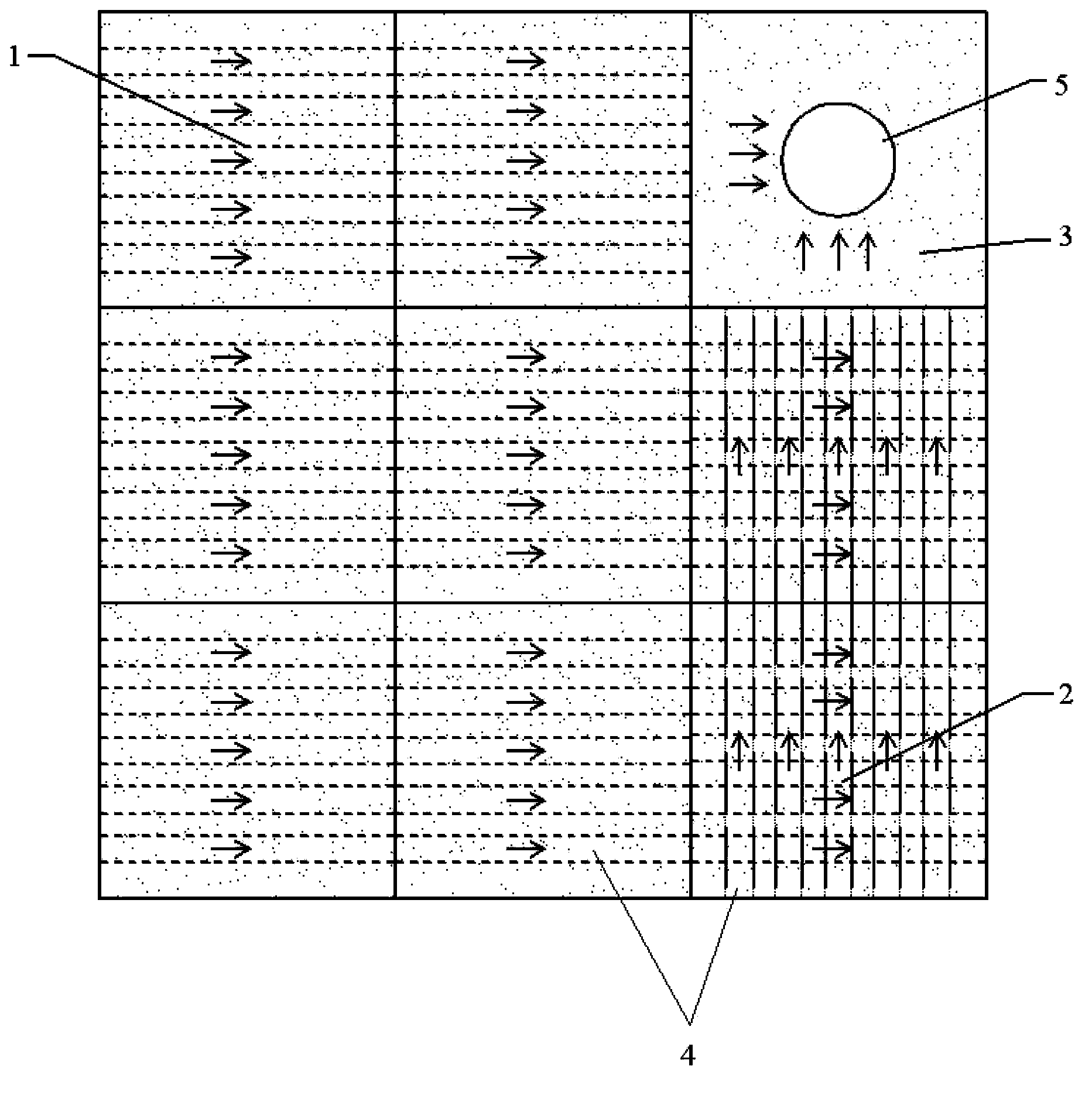

[0048] Such as Figure 4 As shown, the one-way water-conducting brick and the two-way water-conducting brick used in the floor pavement structure of the bathroom in this embodiment are the same as in Embodiment 1, the difference is that the sewer opening is located in the center of the bathroom, and the specific paving method is as follows: First lay a cuboid-shaped water-permeable brick above the sewer, and then lay the one-way water-conducting brick along one of the opposite sides of the water-permeable brick until the water-conducting holes are connected to each other. Two walls; then set the two-way water-conducting brick along the direction of the other opposite side of the water-permeable brick until the other two walls of the bathroom, and ensure that the second water-conducting hole group of the two-way water-conducting brick communicates with each other The other positions are provided with the one-way water guide bricks, and the first water guide hole groups of the o...

Embodiment 3

[0050] Figure 5 It is a top view of one of the arc-shaped one-way water-conducting bricks of the present invention, which includes an anti-seepage layer, a water-permeable layer arranged above the anti-seepage layer, and a water-permeable surface layer arranged above the water-permeable layer. Wherein, the inside of the water-permeable layer is provided with a first group of water-guiding holes, and the first group of water-guiding holes is composed of two water-guiding holes penetrating through the two opposite arc-shaped sides of the water-permeable layer. The anti-seepage layers are parallel, and the two water guide holes extend along the diameter of the circle where an arc-shaped side of the arc-shaped water-conducting brick is located.

[0051] In this embodiment, the central angle corresponding to any arc-shaped side of the arc-shaped one-way water-conducting brick is 30°, and the two water-conducting holes divide the arc-shaped one-way water-conducting brick into three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com