Automatic docking device for temperature measuring probe and temperature measuring gun

A temperature measuring probe and automatic docking technology, which is applied in chucks, metal processing, manipulators, etc., can solve problems such as human hazards, safety hazards, and harsh working environments, and achieve the effects of easy docking, accurate docking, and convenient and fast work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

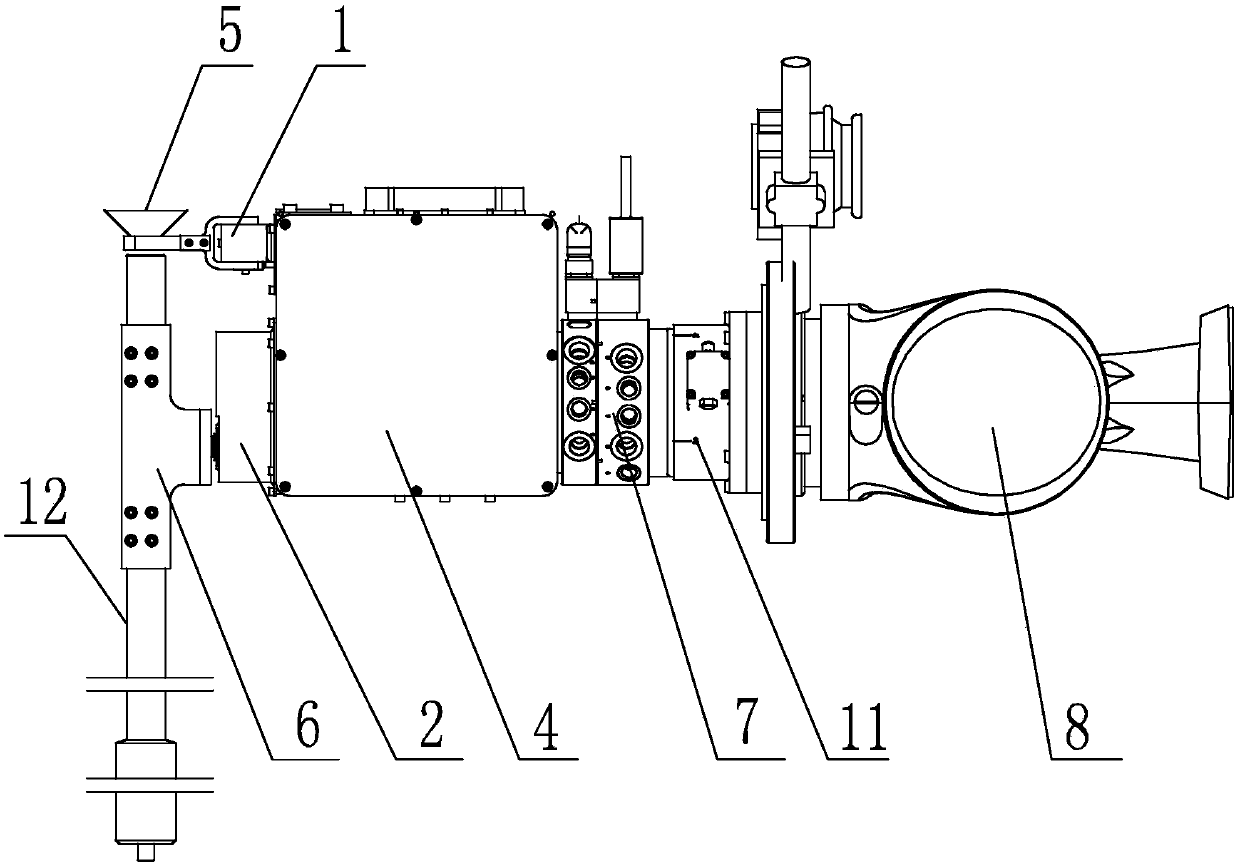

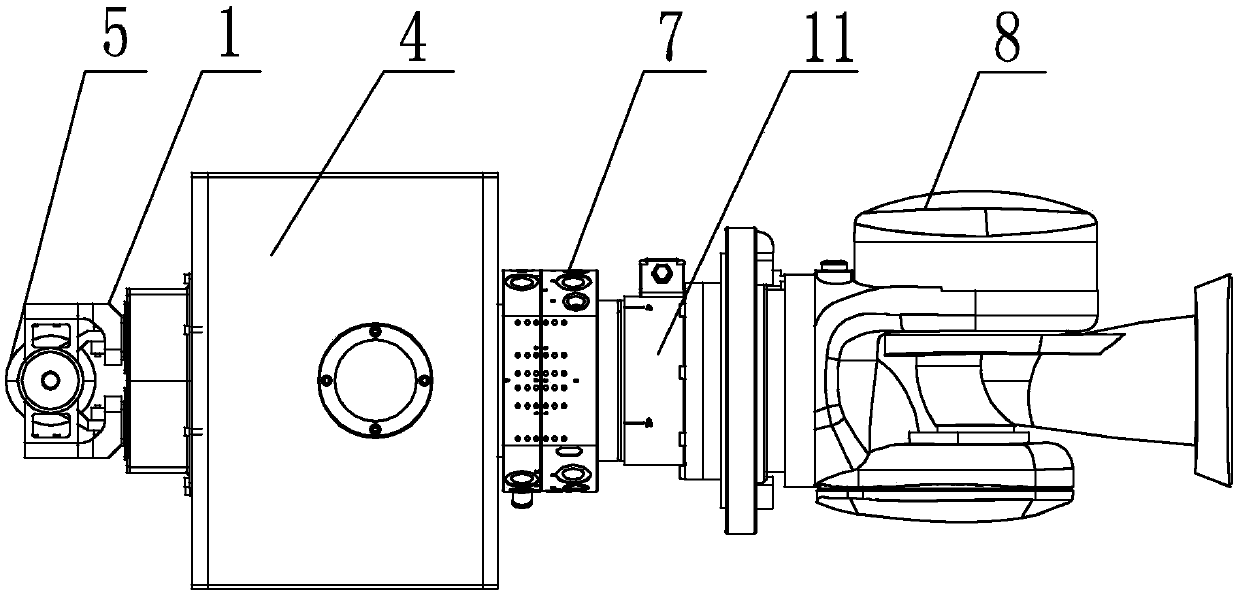

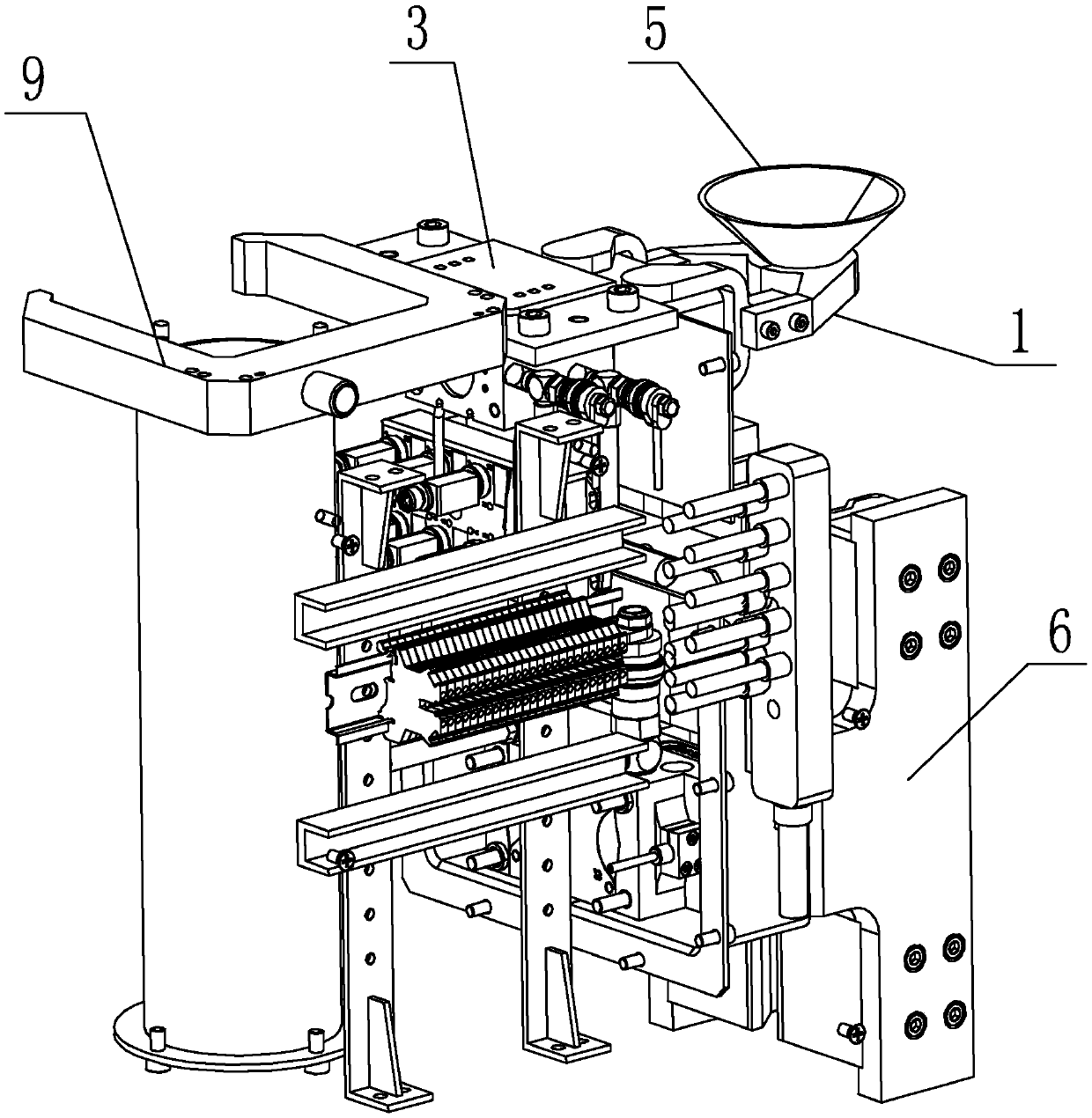

[0018] Specific implementation mode one: combine Figure 1-Figure 5 To illustrate this embodiment, this embodiment includes an angle-opening manipulator 1, a translational manipulator 2, a positioning plate 3, a frame 4, a manipulator 8, two semi-conical plates 5 and two jaws 6;

[0019] The angle-opening manipulator 1, the translational manipulator 2 and the positioning plate 3 are respectively fixed on the frame 4, the frame 4 is set on the manipulator 8, and the two half-tapered plates 5 are respectively fixed on the two fingers of the opening-angle manipulator 1 , when the clamp finger of the angle-opening manipulator 1 is in the clamped closed state, the two half-conical plates 5 are butted together to form a conical cylinder; the axis of the conical cylinder is perpendicular to the positioning plate 3, and the two jaws 6 They are respectively fixed on the two fingers of the translation manipulator 2, and the position of the translation manipulator 2 corresponds to that o...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 and figure 2 To describe this embodiment, a pneumatic quick-change system 7 is also provided between the frame 4 and the manipulator 8 in this embodiment.

[0025] The pneumatic quick change system 7 is preferably a SCHUNK quick change system of the type SWK-160-000-000-SM.

[0026] Because the present invention is applied in the molten iron pretreatment workshop, the working environment is harsher and the dust is relatively large, so the present invention needs to be cleaned frequently, and fast disassembly is indispensable. Setting the pneumatic quick-change system 7 can quickly realize the manipulator and the present invention. separate.

[0027] Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 6 To describe this embodiment, an elastic body 10 is fixedly connected to each jaw 6 in this embodiment.

[0029] The material of the elastic body 10 may preferably be rubber.

[0030] The contact between the elastic body 10 and the temperature measuring probe 12 can increase the friction force of the temperature measuring probe 12 and prevent the temperature measuring probe 12 from slipping during the clamping process.

[0031] Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com