Deformable joint method and deformable joint structure between concrete roof and metal plate roof

A concrete slab and concrete technology, applied in the direction of roof, roof covering, roof using flat/curved slab, etc., to achieve the effect of standard installation, simple construction and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

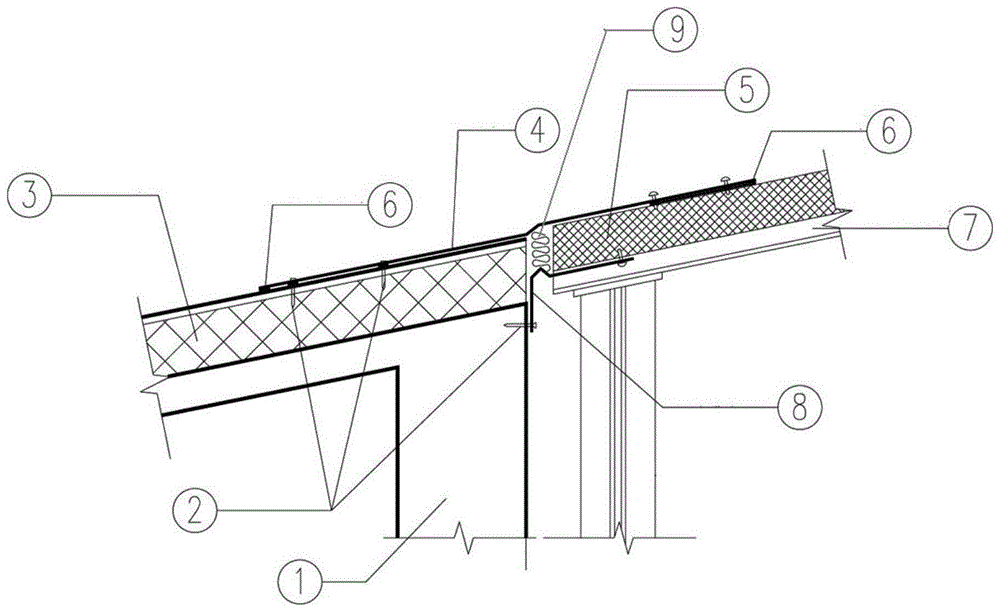

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] When connecting the concrete roof and the metal plate roof, the following steps can be used.

[0024] a. There is a certain gap between the concrete roof and the metal plate roof. The roof keel 7 is aligned with the beam 1 of the concrete roof. First, the iron sheet 8 is installed on the connection between the beam 1 of the concrete roof and the roof keel 7 of the metal plate roof. At the lower end, as a plug, the iron sheet is fixed on the side of the concrete beam close to the deformation joint with steel nails 2, and the iron sheet 8 is fixed on the lower end surface of the roof keel 7 of the metal plate roof with rivets, wherein the iron sheet 8 is in the deformation joint. The length is greater than the length of the deformation joint, that is, the iron sheet 8 has a certain surplus;

[0025] b. Lay the thermal insulation material 3 and the metal sandwich panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com