Stay wire binding tool

A technology for drawing wires and tools, which is applied in the field of tools, can solve the problems of waste of iron wire, easy slipping of iron wire, time-consuming and labor-intensive problems, and achieve the effect of high work efficiency, firm and tight winding, and avoiding contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

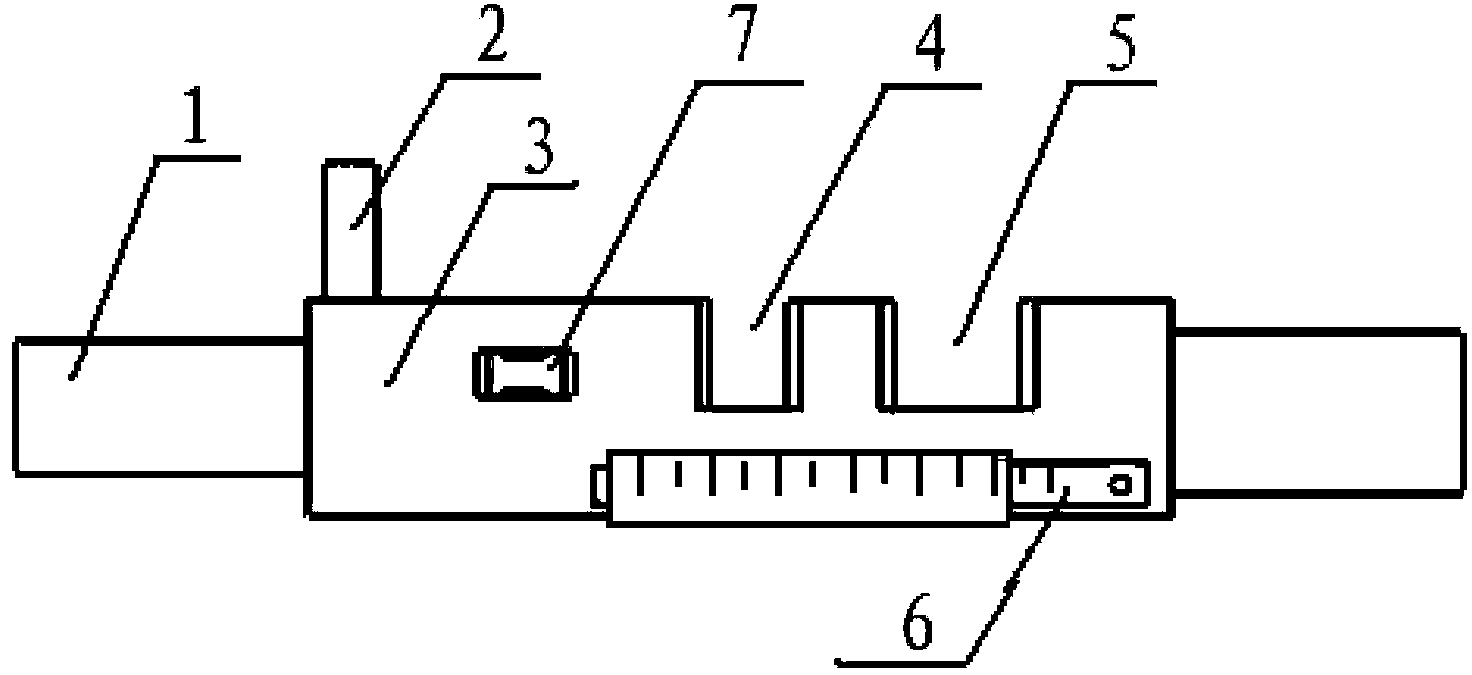

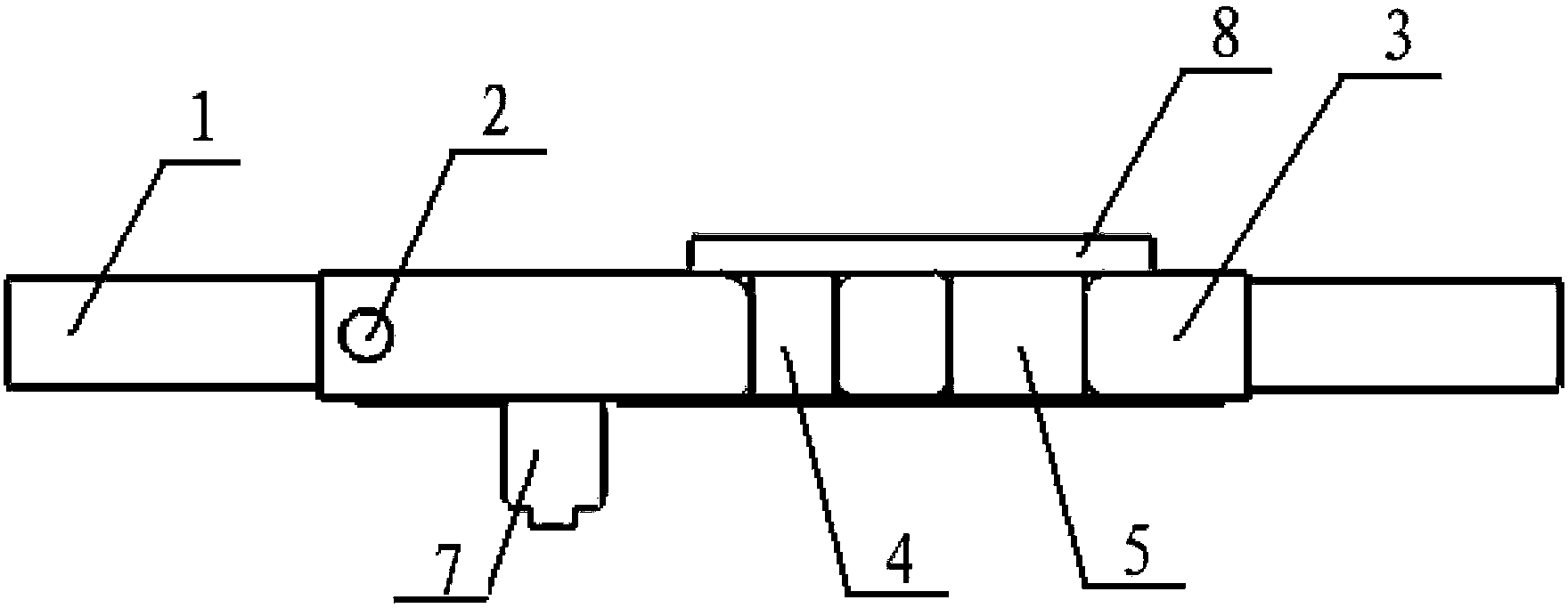

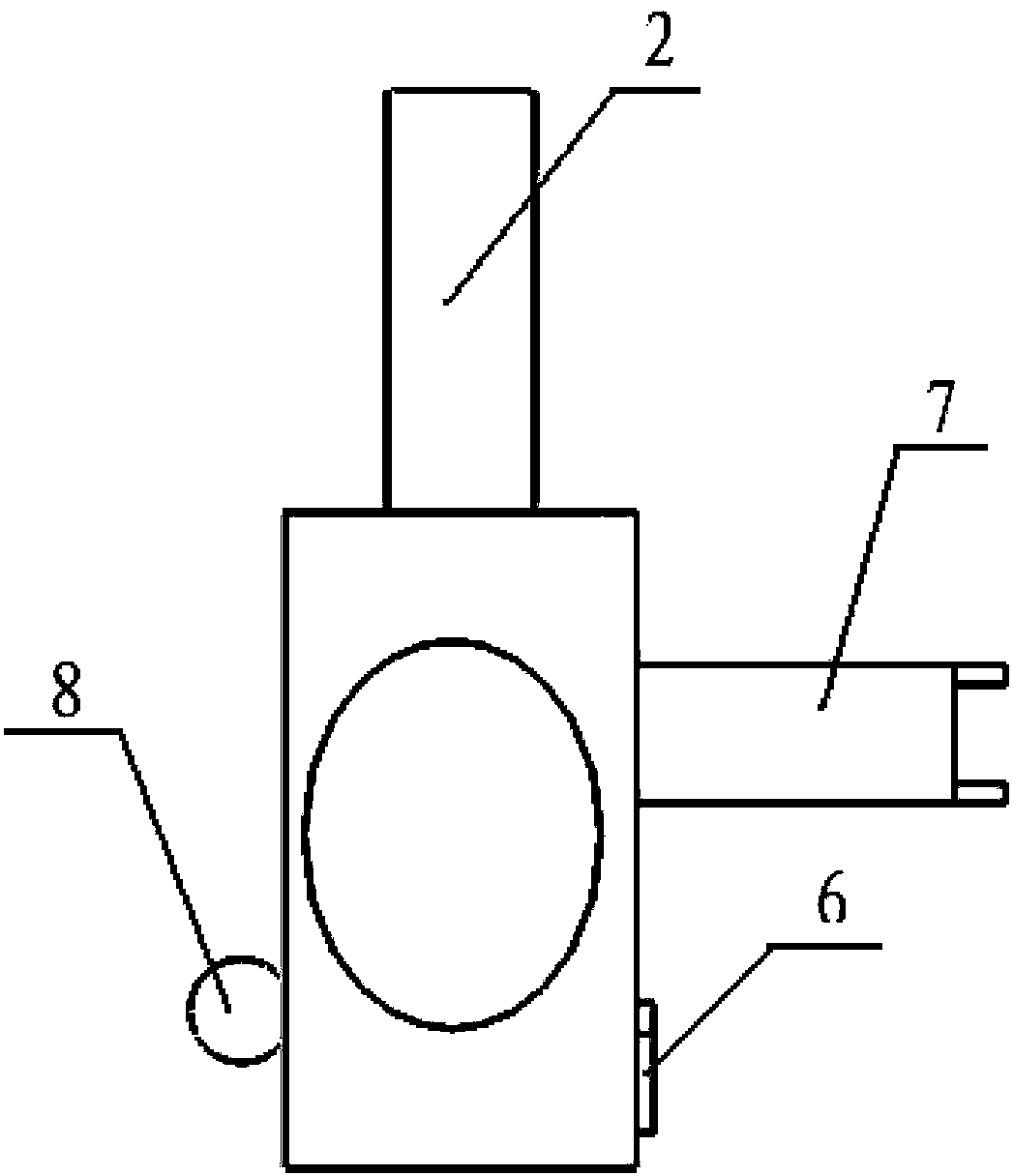

[0023] Pull the wire tool, the structure is as follows figure 1 , figure 2 with image 3 As shown, it includes a strip-shaped insulating board 3, and a handle 1 is fixedly arranged at both ends of the insulating board 3; one end of the side of the insulating board 3 is provided with a hanging wire rod 2, and the hanging wire rod is used for winding and hanging the binding wire. Iron wire, the other end or the middle part of the side of the insulating plate 3 are provided with two wire slots of different widths, and the wire slots are used to block the iron wires. greater than the diameter of the iron wire used; the wire slot is divided into the first wire slot 4 and the second wire slot 5, the width of the first wire slot 4 is smaller than the width of the second wire slot 5, and the first wire slot is located at the second wire slot Two pass through the inner side of the wire trough, the first wire trough is used for winding thinner iron wire, and the second wire trough is...

Embodiment 2

[0030] Pull the line tool, another structure is shown as Figure 4 As shown, the difference with Embodiment 1 is that: the wire groove on the support frame 7 is replaced by a pulley 10, and the pulley 10 is arranged on the upper end of the support rod through a pin; The wheel 9 is hinged at one end of the side of the insulating board 3 through a pin shaft, and the pin shaft is connected perpendicular to the side of the insulating board 3 . Before the pulling wire tool is used, the iron wire of the bundled wire is wound on the winding wheel 9, and the iron wire is output stably through the rotation of the winding wheel during use, and the phenomenon that the iron wire does not shake up and down during the output process makes the The iron wire is wound more stably and compactly on the double-strand stay wire, and the possibility of injury to workers due to the shaking of the iron wire is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com