Method for preventing shaft from cracking in alleviation water-bearing layer by utilizing automatic supply water loss method

An automatic replenishment, water layer technology, applied in vertical shaft equipment, earth-moving drilling, mining equipment, etc., can solve the problems of polluted aquifer, wellbore rupture, difficult control of construction process, etc., to stabilize the water level of the water-loss layer and prevent wellbore rupture , The effect of saving water injection equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

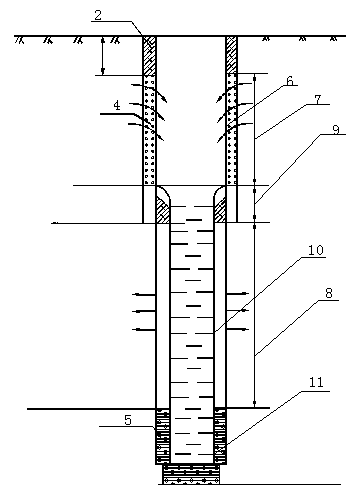

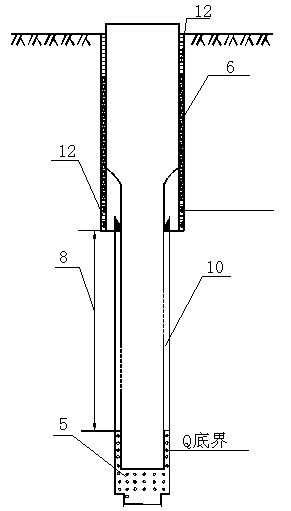

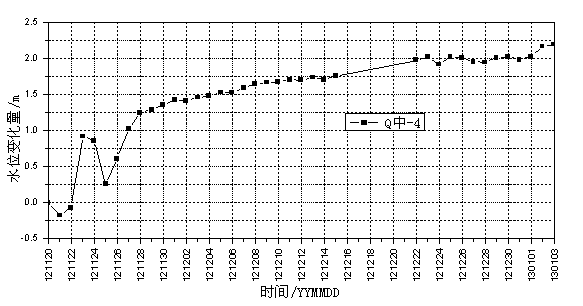

[0055] The automatic compensation drilling technology using interlayer water of the present invention will be described in detail through specific embodiments below.

[0056] Take the westerly shaft as an example.

[0057] 1. Construct the next group of hydrological holes to determine the feasibility of the water replenishment method

[0058] Firstly, a hydrological hole of the lower group of the Quaternary system is constructed at any position within the range of 10-30 meters from the wellbore, and coring and testing are carried out according to the regulations to obtain accurate stratum geological data and accurate upper, middle and lower groups of the Quaternary system. Layer data, to determine the layers of the water-resisting layer (Middle Formation of Quaternary) between the upper water-bearing body and the lower water-bearing body. layer, containing a small amount of sand ginger and iron nodules. The thickness of clay accounts for 75.1% of the thickness of this group,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com