Heavy-duty mining dump vehicle hydraulic oil cylinder/hydraulic valve test table

A technology for mining dump trucks and hydraulic cylinders, applied in fluid pressure actuation system testing, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems of limited test capacity, poor site utilization, inaccuracy and reliability, etc. Achieve the effect of improving the degree of automation and reliability, coordinating and reasonable layout, and ensuring the performance of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

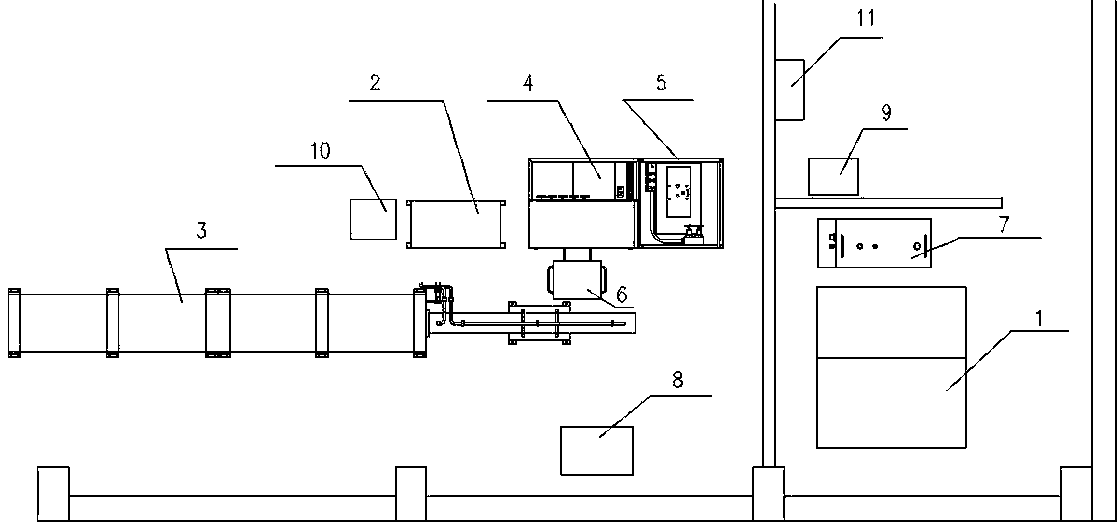

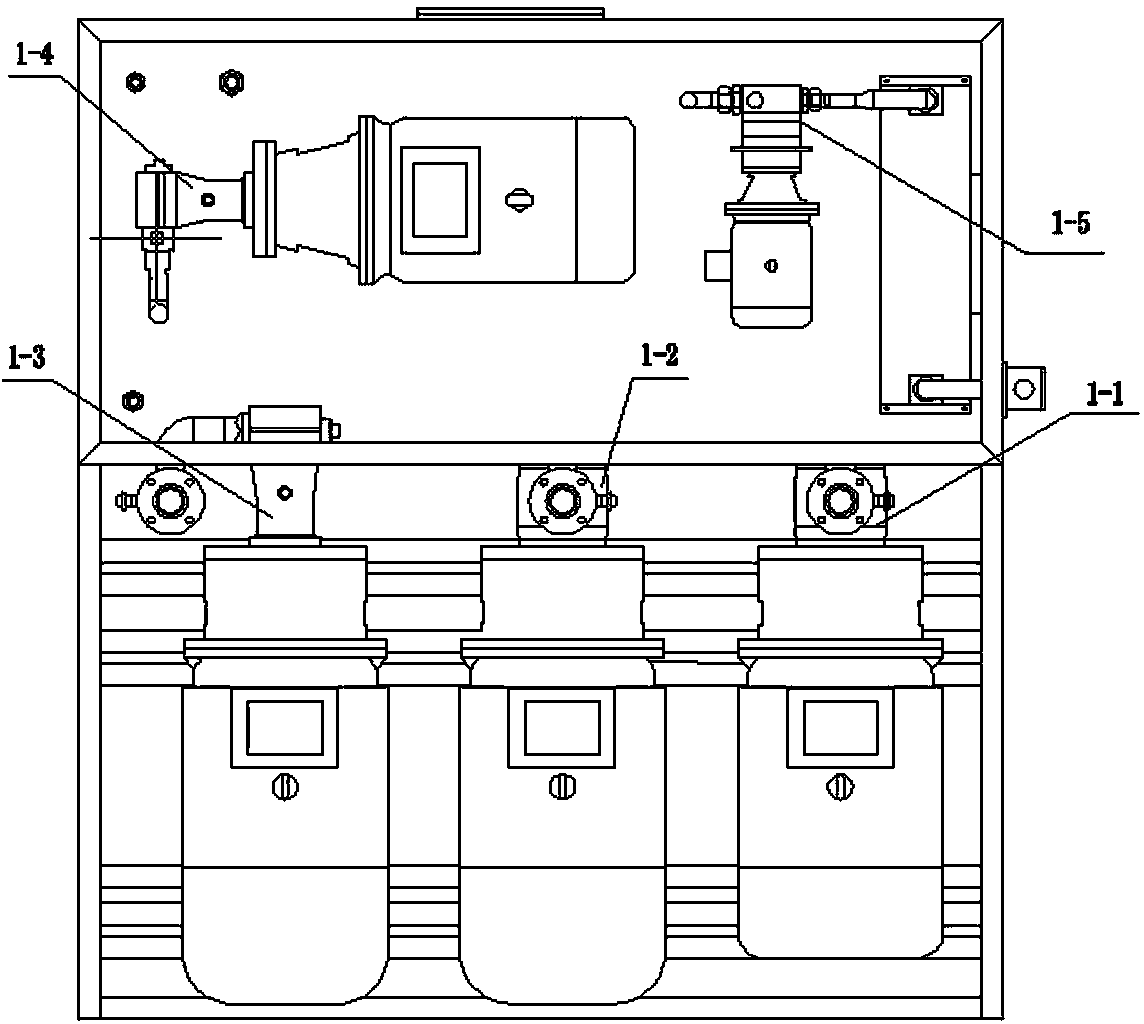

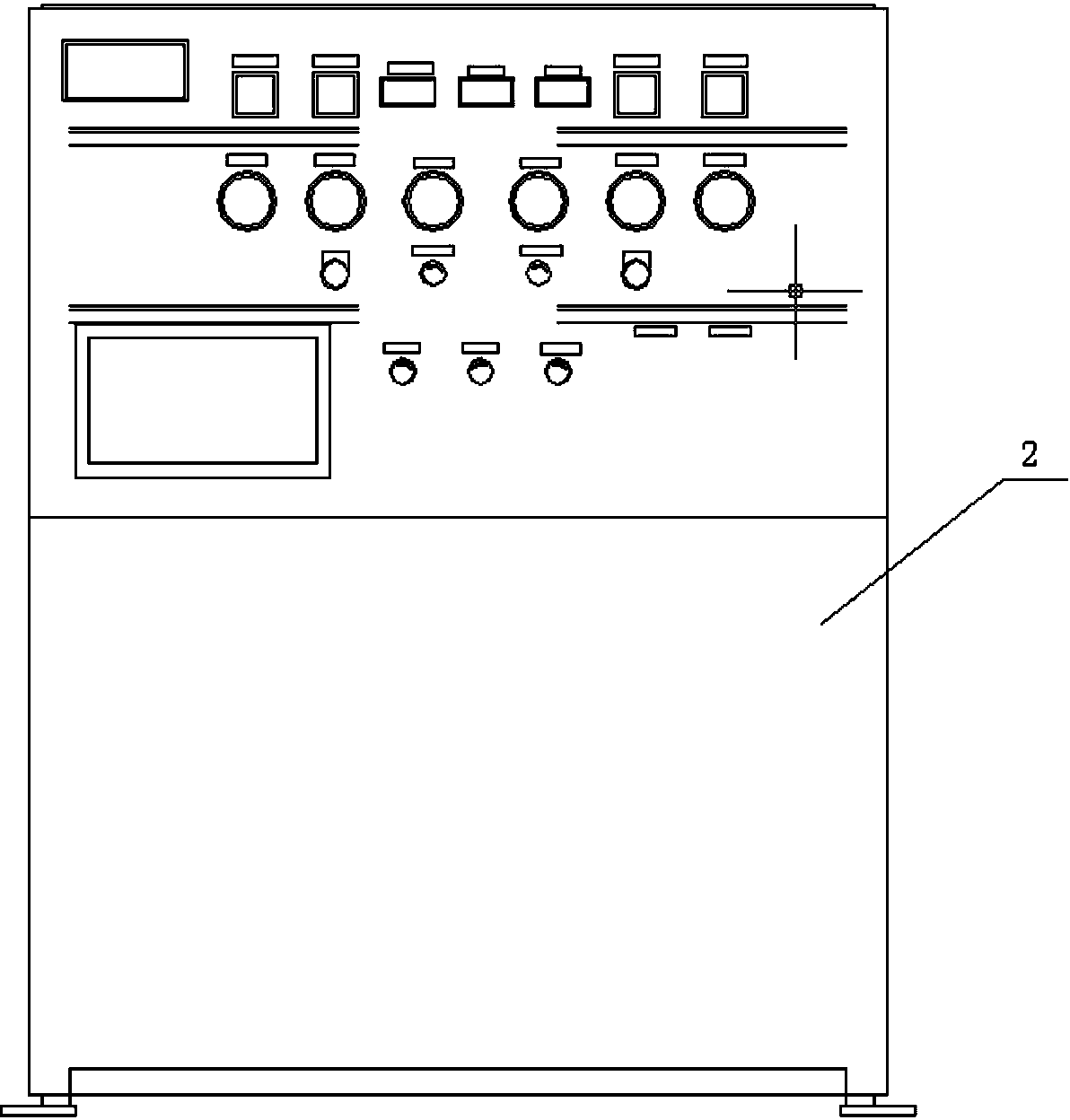

[0031] refer to figure 1 , a heavy-duty dump truck hydraulic cylinder / hydraulic valve test bench, the test bench includes: a power oil source part 1, a cylinder test console 2, a cylinder support bench 3, a valve test console 4, and a test valve installation bench 5. Measuring flow trolley 6, waste oil collection tank 7, power cabinet 8, PLC cabinet 9, electric control operation cabinet 10, industrial computer 11, power oil source part 1 passes through different oil pipes and valve test console 4, oil cylinder The test operation table 2 is connected, the valve test operation table 4 is set on the side of the tested valve installation platform 5, the flow measurement trolley 6 is connected with the valve test operation table 4 or the oil cylinder test operation table 2, and the oil cylinder support table 3 is connected to the waste gas through the oil pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap