Energetic material thermal stability and thermal safety test device and method

A technology of thermal stability and test equipment, applied in the direction of thermal analysis of materials, measuring equipment, and analysis of materials, can solve the problems of cumbersome operation, low degree of automation, bursting, etc., and achieve good test equipment, high degree of automation, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

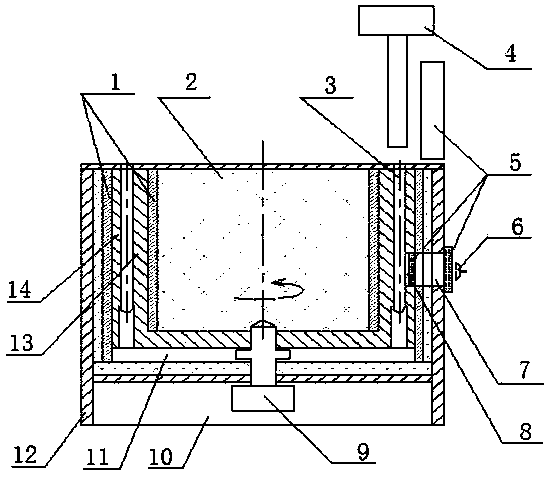

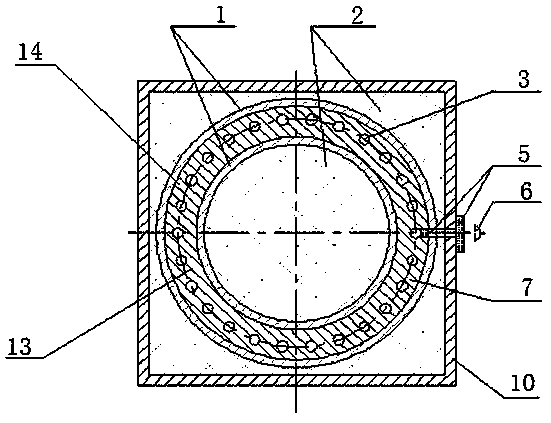

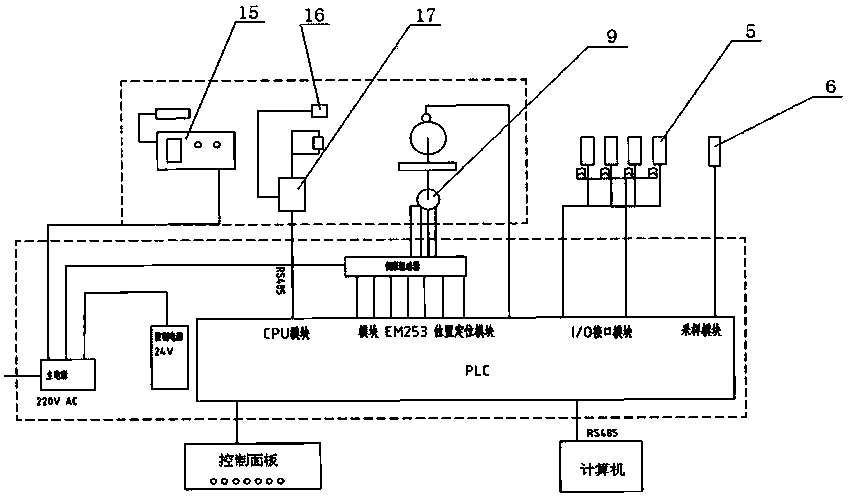

Method used

Image

Examples

Embodiment 1

[0046] Carry out the discoloration test of nitrocellulose methyl violet test paper, and this test is carried out according to the following steps:

[0047] 1) Turn on the thermal stability and thermal safety test device for energetic materials, complete the system self-inspection, set the metal bath temperature to 134.5°C, and start heating;

[0048] 2) Weigh 5 samples of nitrocellulose and prepare methyl violet test paper and test tube;

[0049] 3) First put 5 weighed samples into the test tubes respectively, and then put the methyl violet test paper into the test tubes;

[0050] 4) When the temperature of the constant temperature bath reaches and stabilizes at the set temperature, quickly put the test tube into the test tube hole of the metal bath, set the speed of the servo motor to 0rpm, and turn on the servo motor to make the metal bath rotate;

[0051] 5) When the color sensor collects the chromaticity value of the methyl violet test paper in the test tube and judges by...

Embodiment 2

[0056] Carry out the discoloration test of nitrocellulose methyl violet test paper, the test procedure of this embodiment is carried out according to the same steps as that of Example 1, the difference is that in the step 4) of this embodiment, the rotational speed of the servo motor is set to 10rpm.

[0057] In the present embodiment, the time when nitrocellulose makes the methyl violet test paper change from purple to orange is as shown in Table 2:

[0058] Table 2 Color change time of nitrocellulose 2

[0059]

Embodiment 3

[0061] Carry out the discoloration test of double base gunpowder methyl violet test paper, this test is carried out according to the following steps:

[0062] 1) Turn on the thermal stability and thermal safety test device for energetic materials, complete the system self-inspection, set the temperature of the metal bath to 120°C, and start heating;

[0063] 2) Weigh 5 double-base propellant samples and prepare methyl violet test paper and test tubes;

[0064] 3) First put 5 weighed samples into the test tubes respectively, and then put the methyl violet test paper into the test tubes;

[0065] 4) When the temperature of the constant temperature bath reaches and stabilizes at the set temperature, quickly put the test tube into the test tube hole of the constant temperature bath, set the speed of the servo motor to 0 rpm, and turn on the servo motor to rotate the metal bath;

[0066] 5) When the color sensor collects the chromaticity value of the methyl violet test paper in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com