A Multi-bus Based Microwave Metallurgy Control Method

A technology of microwave metallurgy and control method, applied in the field of control, can solve the problems of low communication performance and processing capacity, and achieve the effects of improving data communication capacity, improving scalability, and wide practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

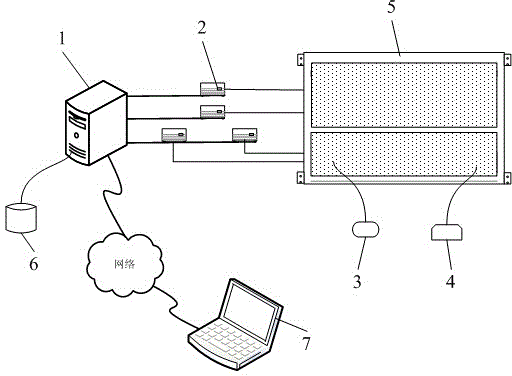

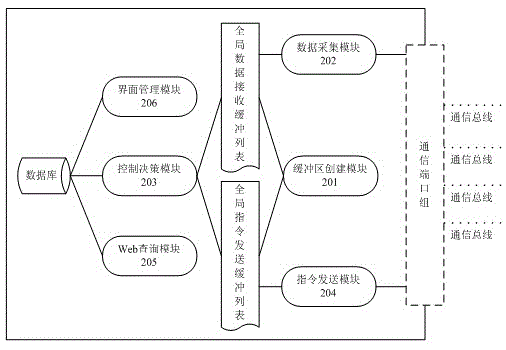

[0027] A microwave metallurgical control system based on multi-bus, including main control computer, database, multiple programmable controllers, various sensors, relays and microwave metallurgical devices, multiple communication ports on the main control computer, programmable controller It is connected with the main control computer in a multi-bus mode, and the main control computer is connected to the network. The main control computer includes:

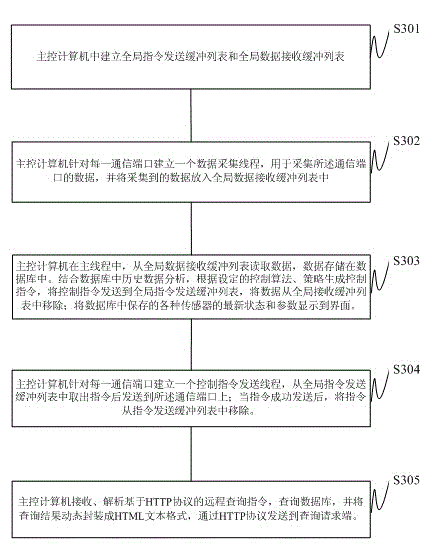

[0028] The buffer creation module is used to establish a global instruction sending buffer list and a global data receiving buffer list;

[0029] The data collection module is used to collect the data sent by the programmable controller on each bus to the main control computer in real time, specifically including: setting up a data collection thread for each communication port to collect the data o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com