Composite absorbent for capturing flue gas carbon dioxide based on membrane contactor and its application method

A technology of membrane contactor and carbon dioxide, applied in the fields of chemical industry, resources and environment, to achieve the effect of not easy to degrade, strong absorption capacity, and small reaction heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

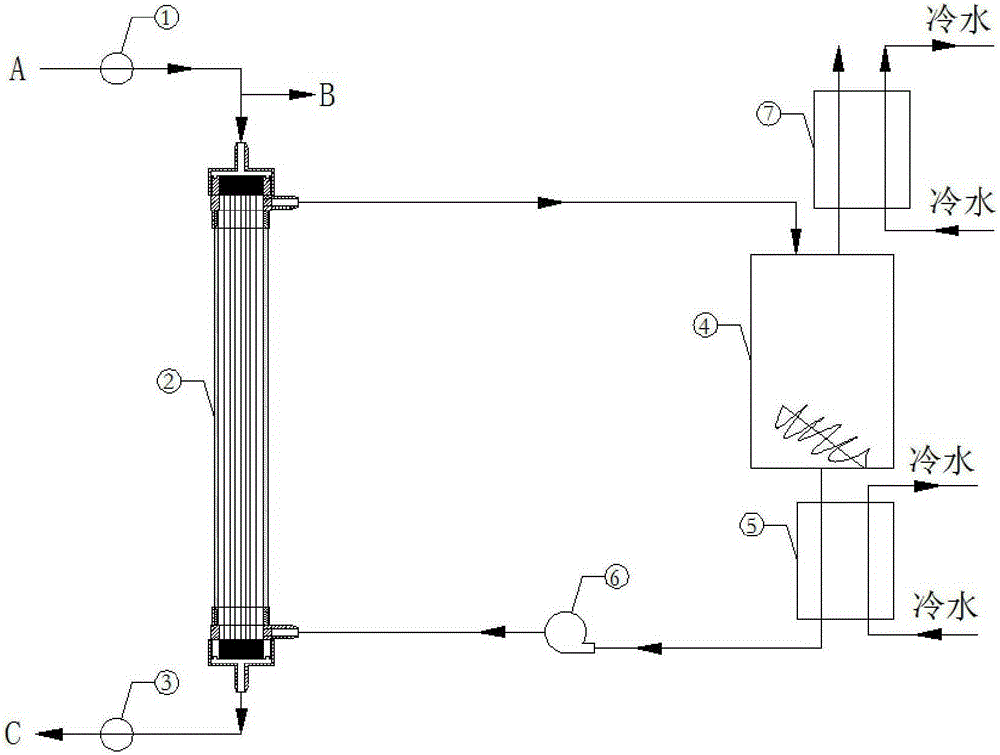

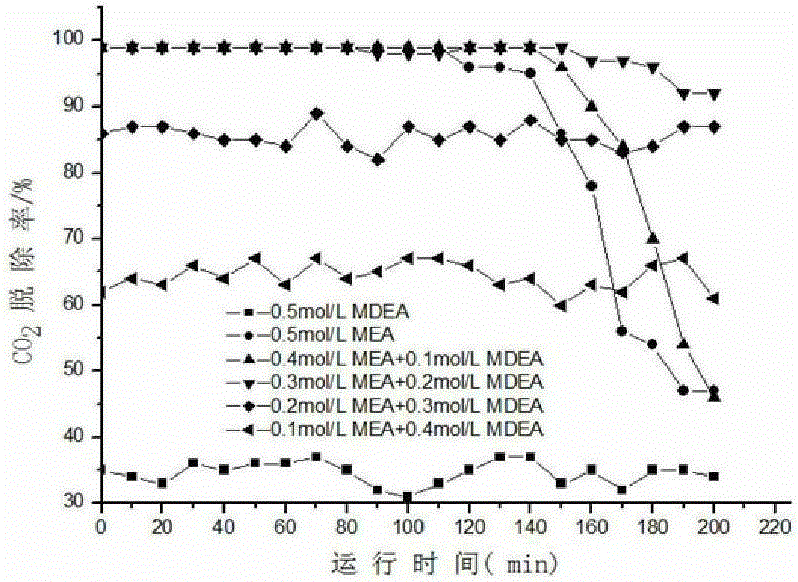

[0031] Embodiment 1: as Figure 1 to Figure 6 As shown, in this example, the composite absorbent based on the membrane contactor to capture flue gas carbon dioxide: it is formed by compounding MDEA and MEA with a molar ratio of 2:3; the composite absorbent based on the membrane contactor to capture flue gas carbon dioxide: It is a compound absorbent for capturing carbon dioxide gas in flue gas with a total amine concentration of 0.5mol / L.

[0032] Add the composite absorbent solution based on the membrane contactor to capture flue gas carbon dioxide into the desorber 4, turn on the agitator in the desorber 4, mix the absorption liquid in the system evenly, and heat the absorption liquid in the desorber 4 to 105°C , adjust the outlet valve of the gas path, and let in CO with a concentration of 15% at the inlet point A at an outlet flow rate of 1L / min. 2Mixed gas (real flue gas concentration), open cooler 5, cooler 7 at the same time, and turn on the absorption liquid pump 6 to...

Embodiment 2

[0034] Example 2: The compound absorbent based on membrane contactor to capture flue gas carbon dioxide in this example: It is formed by compounding MDEA and PG with a molar ratio of 2:3; the compound absorbent based on membrane contactor to capture flue gas carbon dioxide : It is a compound absorbent for capturing carbon dioxide gas in flue gas with a total amine concentration of 0.5mol / L.

[0035] Add the composite absorbent solution based on the membrane contactor to capture flue gas carbon dioxide into the desorber 4, turn on the agitator in the desorber 4, mix the absorption liquid in the system evenly, and heat the absorption liquid in the desorber 4 to 105°C , adjust the outlet valve of the gas path, and let in CO with a concentration of 15% at the inlet point A at an outlet flow rate of 1L / min. 2 Mixed gas (real flue gas concentration), turn on cooler 5 and cooler 7 at the same time, and turn on the absorption liquid pump 6 to make the absorption liquid go along the de...

Embodiment 3

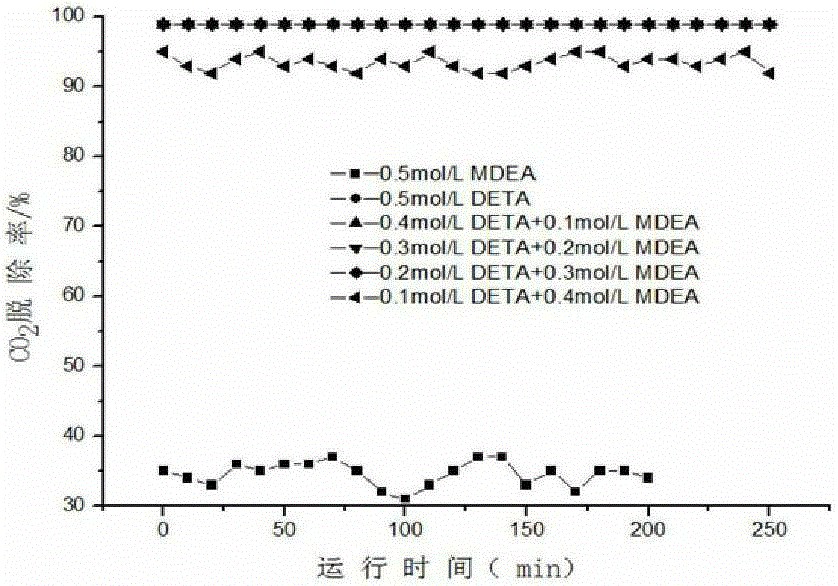

[0037] Example 3: The compound absorbent based on membrane contactor to capture flue gas carbon dioxide in this example: it is formed by compounding MDEA and DETA with a molar ratio of 1:4; the compound absorbent based on membrane contactor to capture flue gas carbon dioxide : It is a compound absorbent for capturing carbon dioxide gas in flue gas with a total amine concentration of 0.5mol / L.

[0038] Add the composite absorbent solution based on the membrane contactor to capture flue gas carbon dioxide into the desorber 4, turn on the agitator in the desorber 4, mix the absorption liquid in the system evenly, and heat the absorption liquid in the desorber 4 to 105°C , adjust the outlet valve of the gas path, and let in CO with a concentration of 15% at the inlet point A at an outlet flow rate of 1L / min. 2 Mixed gas (real flue gas concentration), turn on cooler 5 and cooler 7 at the same time, and turn on the absorption liquid pump 6 to make the absorption liquid go along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com