Plate model prediction control method

A technology of model predictive control and plate shape, applied in the direction of contour control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

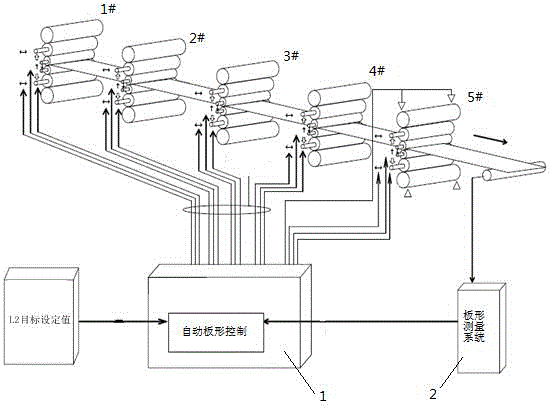

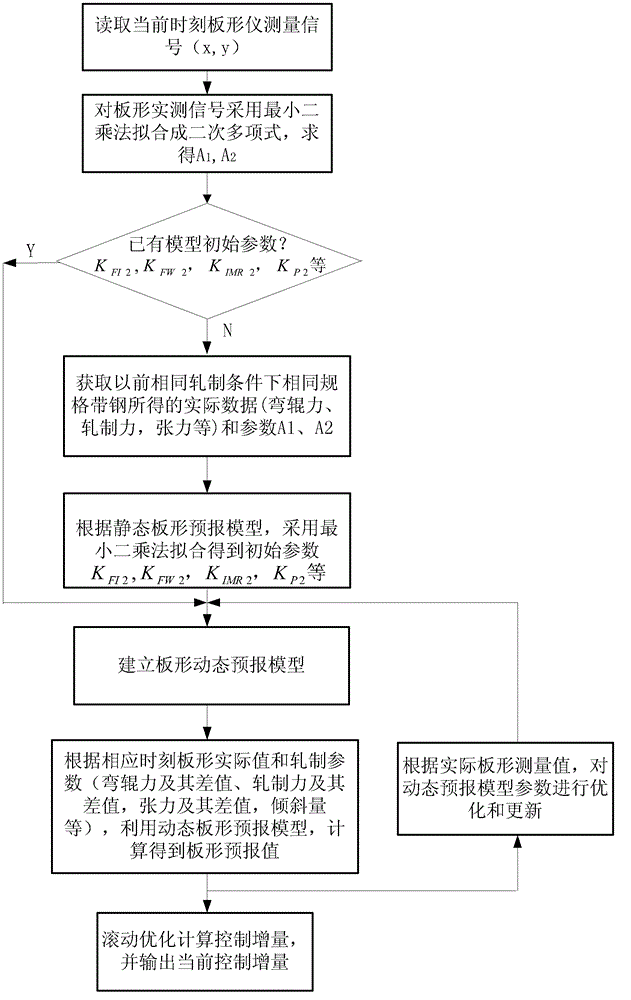

[0057] The shape control system of this embodiment is as follows: figure 1 As shown, it mainly includes a rolling control computer 1 whose control output terminals are respectively connected to each roll through an interface unit, and a shape meter 2 whose signal output terminals are connected to corresponding ports of the rolling control computer. The detection mechanism in the shape meter 2 has a distance of 1 = 3.2m from the exit of the 5# frame (also referred to as 5 frame) to the shape measurement roller. When the strip running speed V figure 2 ):

[0058] The first step is to use the least square method to regress the quadratic curve on a set of standard measured flatness data collected by the flatness meter to obtain the quadratic flatness component in the actual flatness curve (that is, the quadratic term coefficient A 2 ——reflects the symmetrical shape) and the first-order shape component (namely, the first-order coefficient A 1 ——reflecting asymmetric plate shape),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com