Electronic drive-by-wire booster control system

A control system and booster technology, applied in the directions of brakes, brake transmissions, transportation and packaging, etc., can solve the problems of insufficient brake booster, inaccurate data, insufficient motor efficiency, etc., to avoid control lag and improve control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

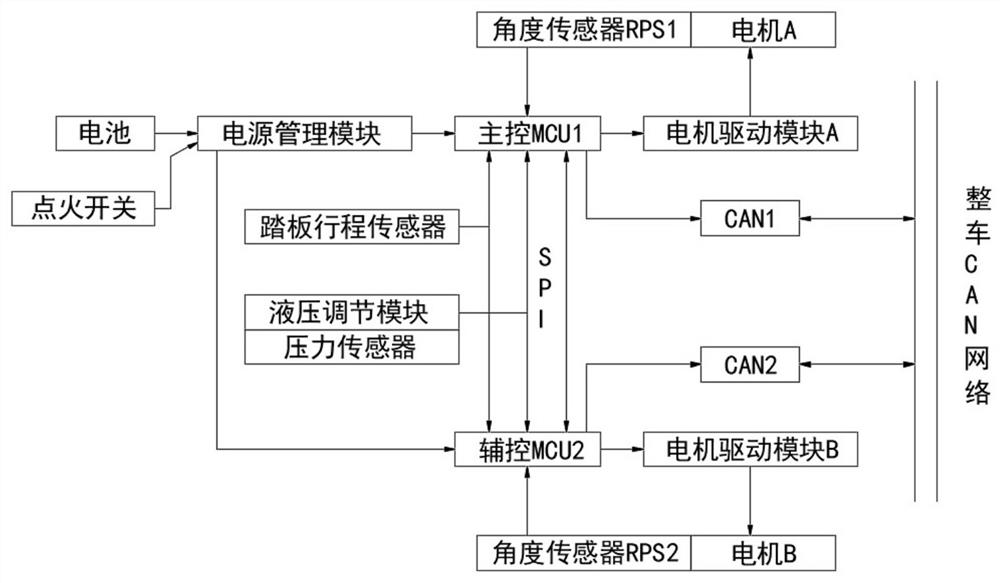

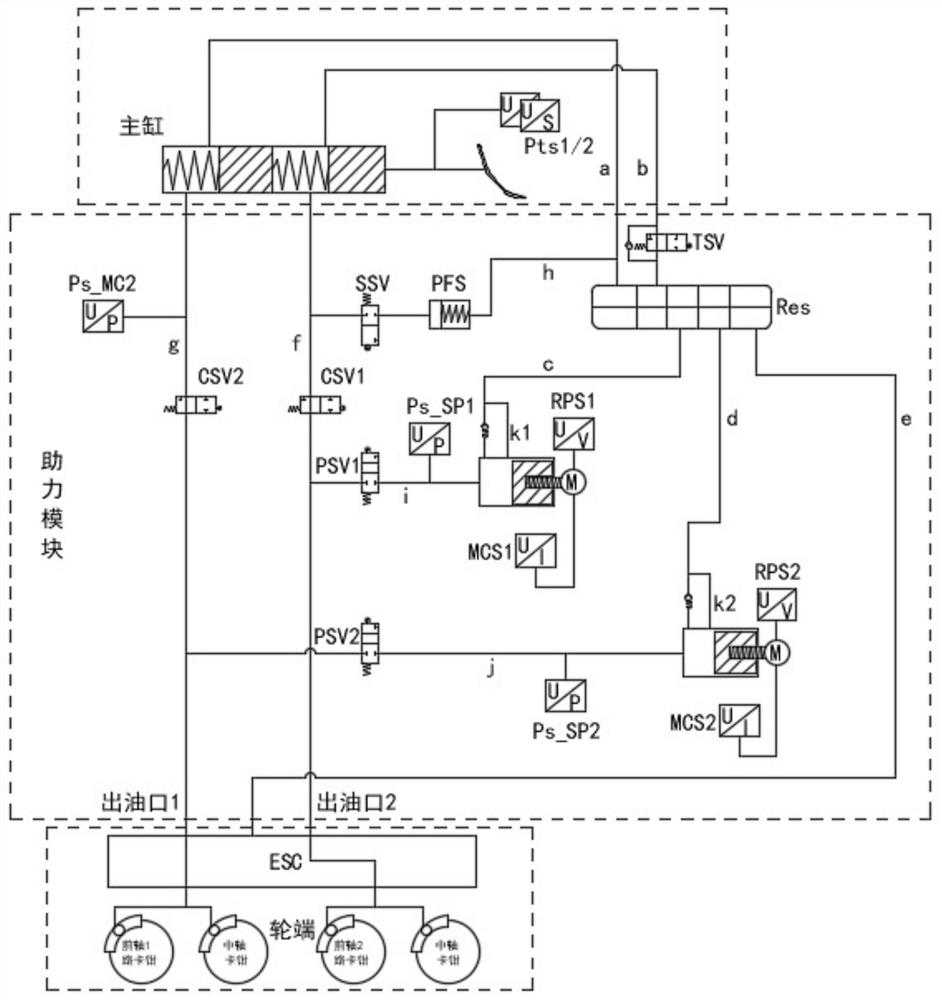

[0025] see figure 1 and figure 2 , the present invention provides a technical solution: an electronic drive-by-wire booster control system, including an ECU module, a pedal stroke sensor module, a motor module, a hydraulic adjustment module, and a pressure sensor module. The ECU module includes a main control MCU1, an auxiliary control MCU2, CAN1 and CAN2, CAN1 and CAN2 are used for signal interaction with the CAN network of the vehicle. The motor module includes a motor, a motor drive module and a motor angle sensor module. The motor includes motor A and motor B. The motor drive module includes motor drive module A and motor The drive module B, the motor angle sensor module includes angle sensors RPS1 and RPS2, the motor A sub-pump A builds the pressure, the motor B controls the sub-pump B builds the pressure, the main control MCU1 controls the motor A, the auxiliary control MCU2 controls the motor B, and the hydraulic adjustment module includes Master cylinder, booster mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com