Automatic stability detecting method for process of CO2 electric arc welding short circuit transition welding

A short-circuit transition welding and automatic detection technology, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of lack of theoretical explanation support and scientificity that needs further verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

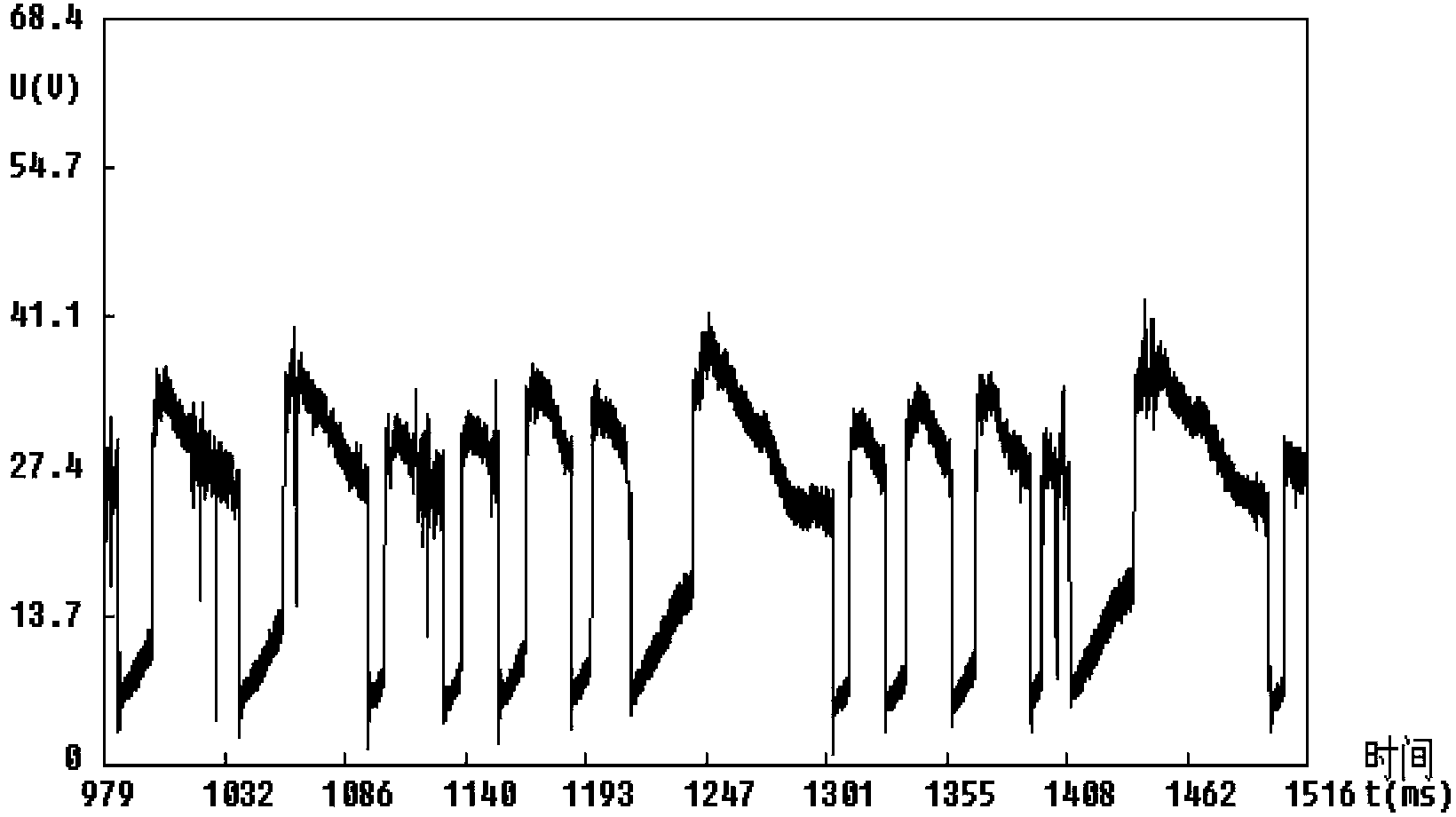

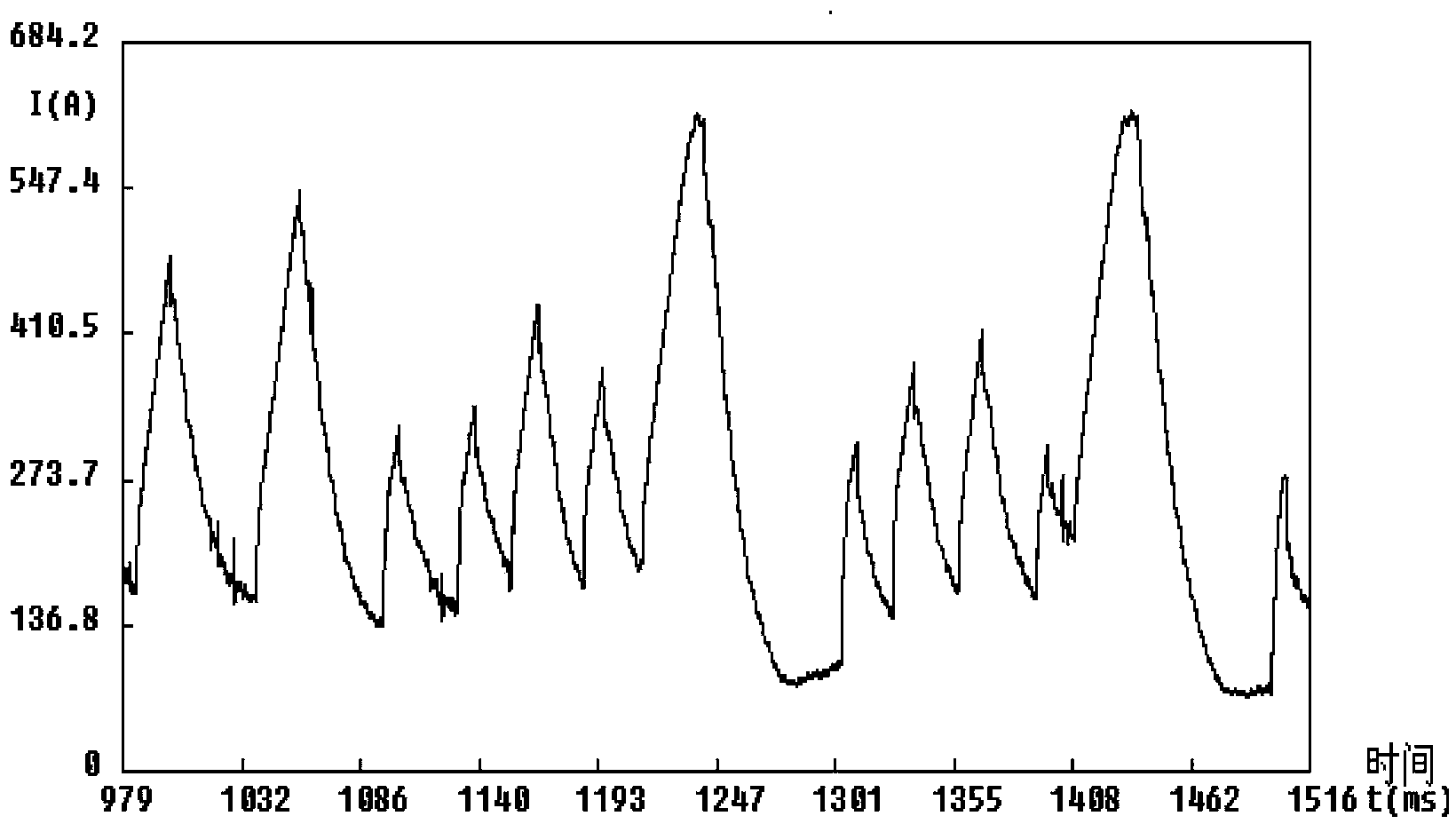

[0058] CO in this example 2 The automatic detection method for the stability of the arc welding short-circuit transition welding process adopts a test platform including an industrial computer, an arc welding process detector, a welding wire conveying mechanism, a walking trolley, a guide rail and an oscilloscope, and the arc welding process detector includes a voltage sensor and a current sensor , the voltage sensor used is a voltage divider, and the current sensor used is a Hall current sensor. During the test, the welding equipment adopts the plate surfacing welding method with the test piece as the Q235 steel plate, the welding speed is 400mm / min, CO 2 The gas flow rate is 16L / min, the diameter of the welding wire is 1.2mm, and the extension length of the welding wire is 12mm.

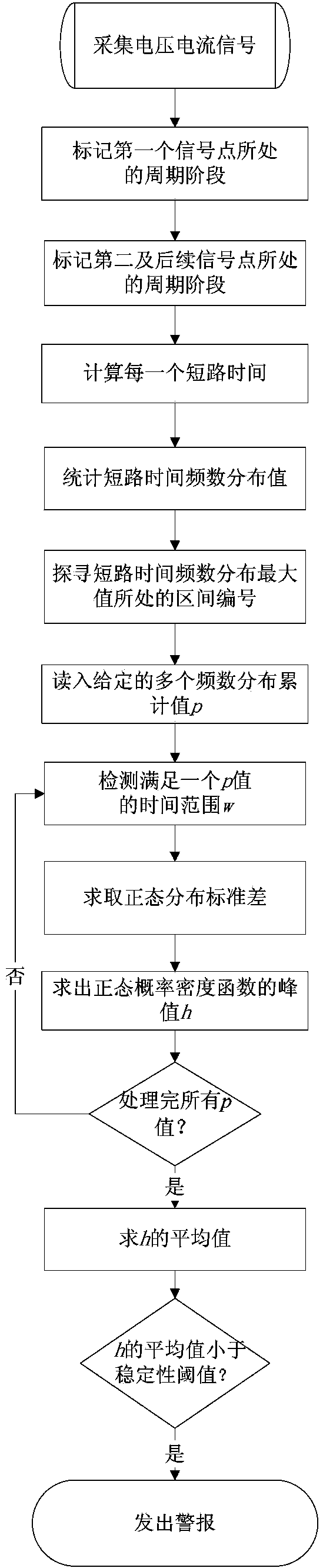

[0059] Such as figure 1 As shown, the CO of this example 2 The automatic detection method for the stability of arc welding short-circuit transition welding process comprises the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com