Distribution device of soft object packaging machine

A material distribution device and packaging machine technology, applied in the direction of packaging, etc., can solve the problems of large weight difference of cut materials, low production efficiency, large labor input, etc., and achieve the effect of cutting evenly, reducing labor and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

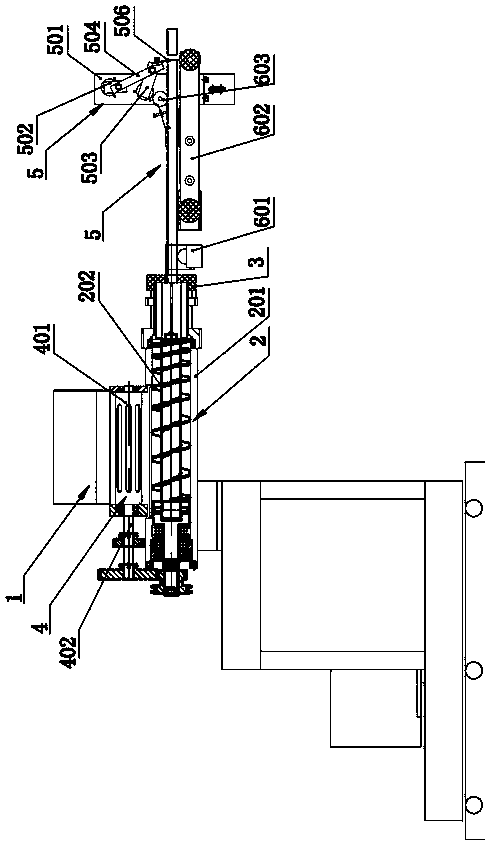

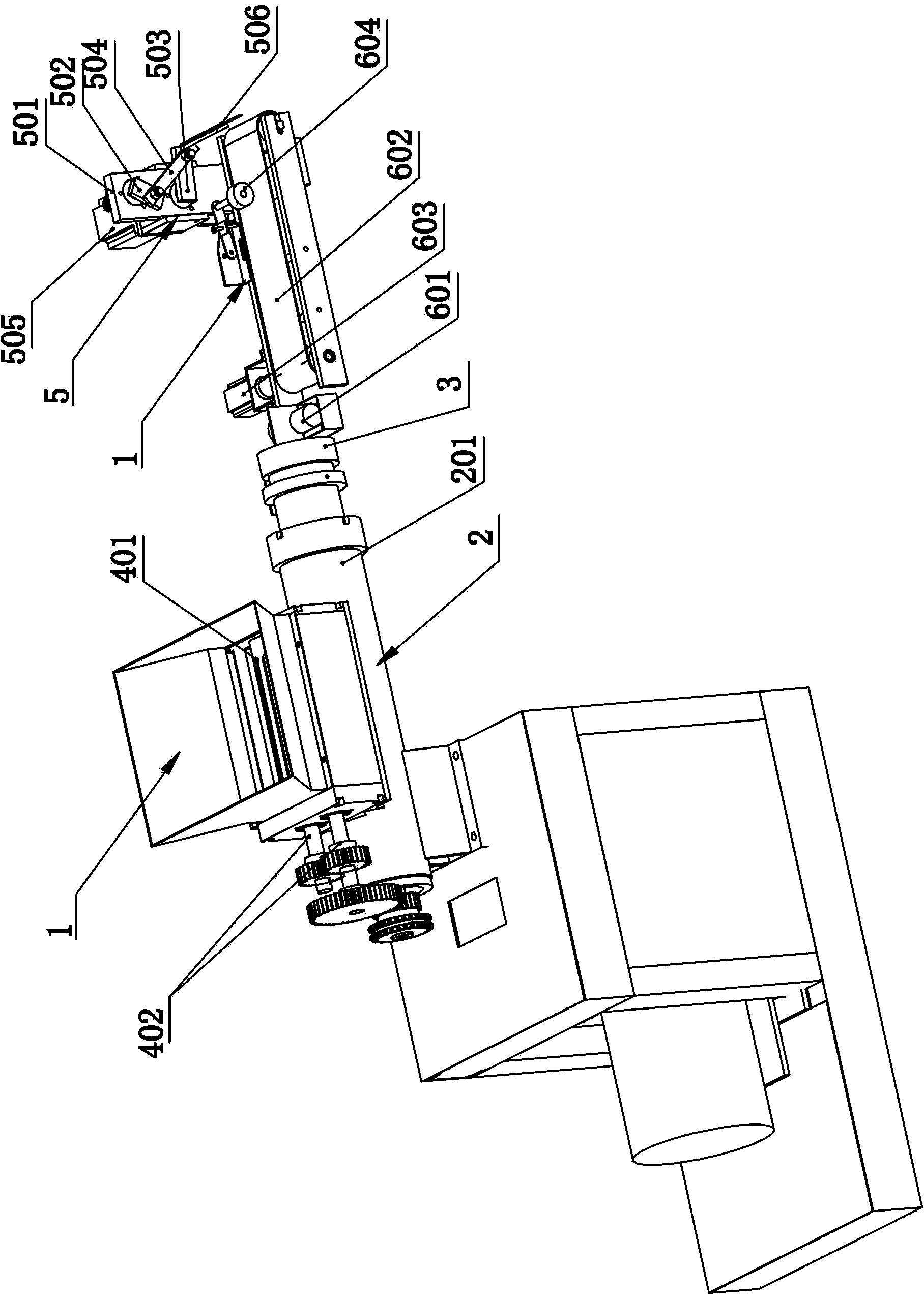

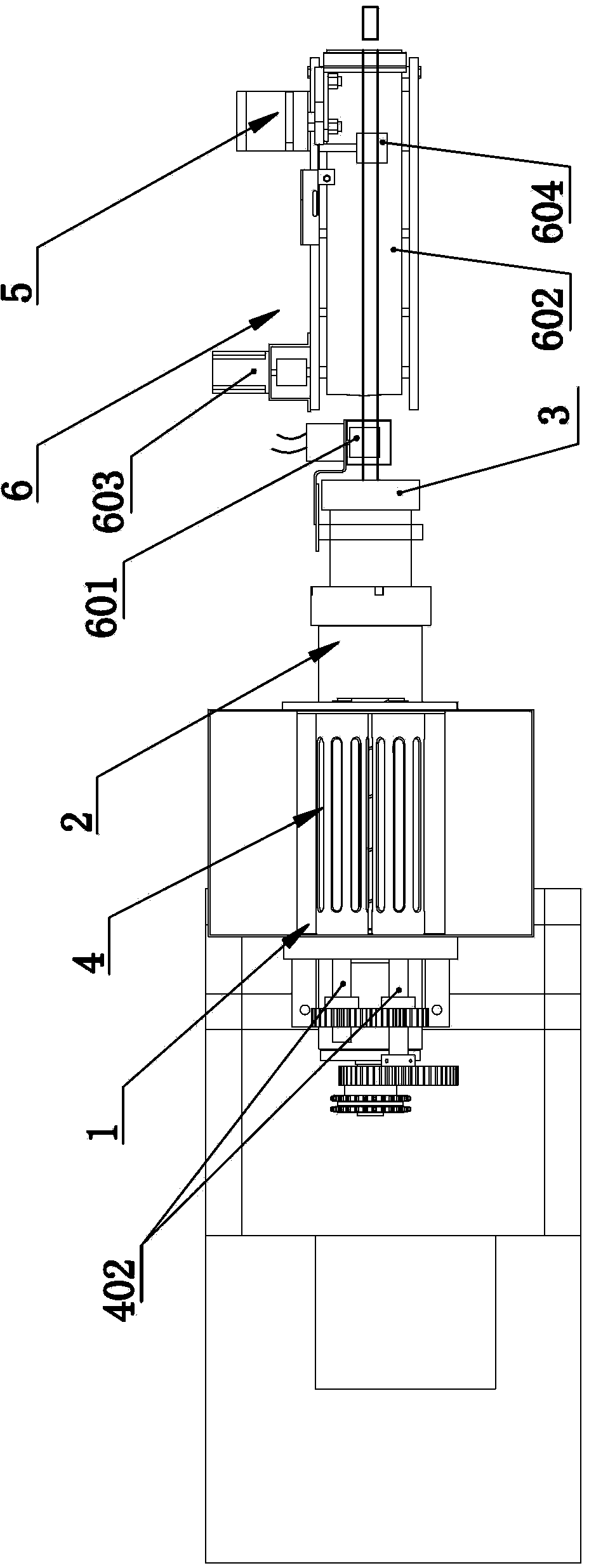

[0015] See attached figure 1 to attach image 3 , the distributing device of the soft object packaging machine disclosed in the present invention includes a hopper 1 and a material extruding mechanism 2. The material extruding mechanism 2 includes a housing 201 and a screw 202 arranged in the housing 201. The housing 201 The upper part is provided with a feed port connected with the hopper 1, and the housing 201 is provided with a discharge port corresponding to the axial end of the screw rod 202, and the housing 201 is provided with an extrusion die opening 3 corresponding to the discharge port position, and the screw rod 202 The thread pitch is gradually increased from one end of the screw 202 corresponding to the discharge port to the other end. The bottom of the hopper 1 is provided with a pressing mechanism 4 that presses the material in the hopper into the extrusion mechanism. The rear is provided with material cutting mechanism 5. By adopting the above scheme, the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com