Leakage-injection production device for non-oxide chalcogenide glass and production method thereof

A chalcogenide glass and non-oxide technology, which is applied in glass production, glass molding, glass furnace equipment, etc., can solve the problem of affecting the imaging quality of products, restricting the quality of non-oxide chalcogenide glass, batch and production costs, and failure to achieve To meet the requirements and other issues, achieve good infrared transmission performance, high work efficiency, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the technical content, features and effects of the present invention, the following examples are listed and described in detail below in conjunction with the accompanying drawings.

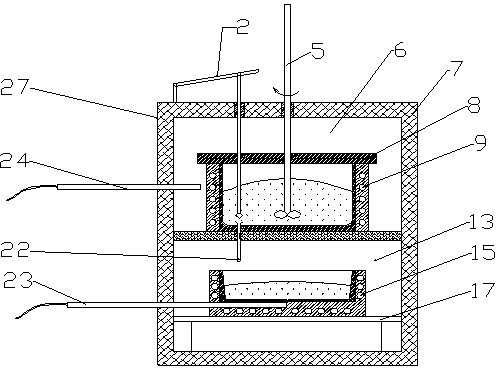

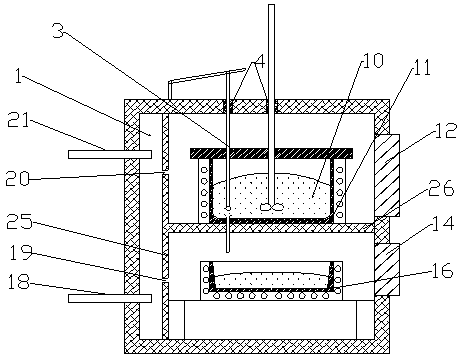

[0025] The furnace main body 27 is surrounded by steel plates to form a frame structure, and the inner layer of the furnace main body 27 is followed by the insulation layer 7 and the inner container, thus forming the inner cavity of the device. The inner cavity of the furnace main body 27 is divided into three parts: the melting chamber 6, the forming chamber 13 and the atmosphere control chamber 1 by the horizontal partition 26 and the vertical partition 25.

[0026] The melting chamber 6 is composed of a crucible heating device 9, a quartz crucible 11, a stirrer 5, a quartz cover plate 8, a temperature control device and a flow rate control device.

[0027] The flow rate control device is composed of a sphere at the lower part of the tie rod 3 and a hemisphere at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com