Grouting device

A grouting and grouting pipe technology, which is applied in safety devices, fillings, mining equipment, etc., can solve the problems that the mud cannot cover the oxidation zone, spontaneous combustion of leftover coal, grouting blind areas, etc., to increase the density, increase the grouting area, reduce the The effect of the probability of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

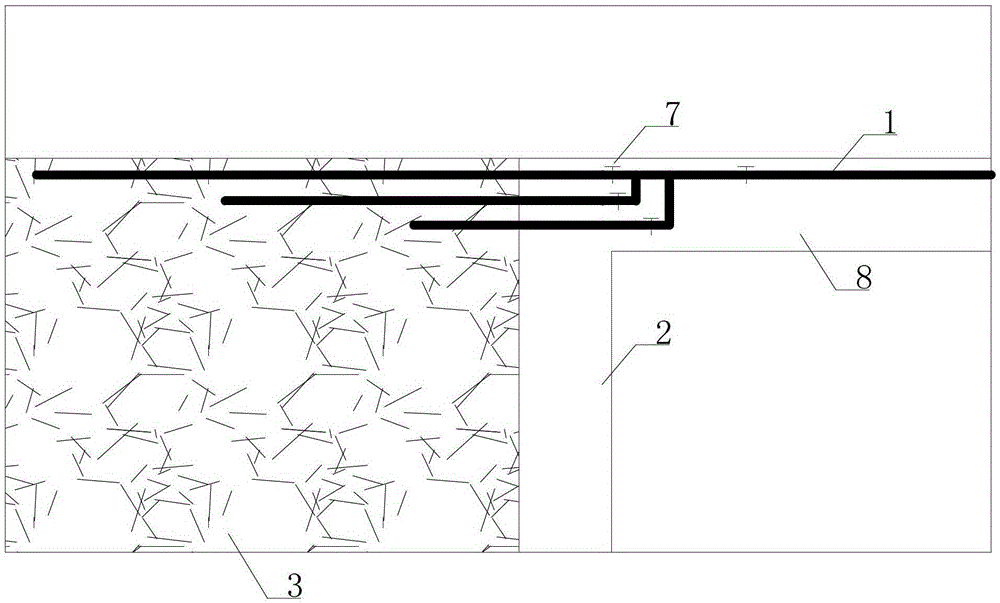

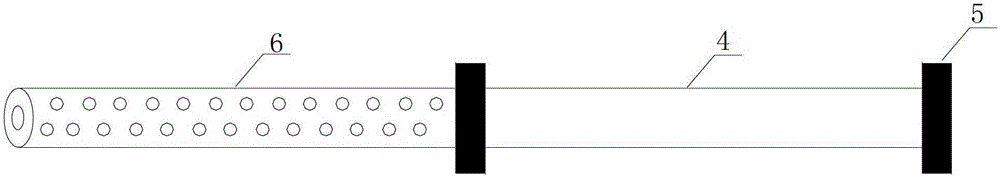

[0019] figure 1 It is a structural schematic diagram of Embodiment 1 of the grouting device of the present invention, as figure 1 As shown, the grouting device of the present invention includes a plurality of grouting pipes and gate valves 7, the number of grouting pipes can be two or three, the number of gate valves 7 can be the same as the number of grouting pipes, and each gate valve 7 is installed on a grouting pipe The grouting parts of multiple grouting pipes are evenly spaced on the upper part of the goaf, and the gate valve 7 is used to control each grouting pipe to perform time-sharing intermittent grouting. The main grouting pipe 1 of the upward groove 8 provides yellow mud for the whole grouting device, and the grouting pipe is used for grouting the goaf.

[0020] During the specific grouting process, you can first open the figure 1 The gate valve 7 of the uppermost grouting pipe in the center is closed for a period of time after grouting, and then the gate valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com