Cardan joint capable of compensating abrasion of sealing device

A sealing device and oil seal technology, which is applied in the direction of elastic couplings, mechanical equipment, couplings, etc., can solve the problem of unsatisfactory waterproof and sandproof effect of the dust cover, the main lip of the oil seal ring cannot be compensated, and the oil seal of the universal joint is easy Wear and other problems, to ensure the waterproof and sandproof function, improve the service life, and improve the effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

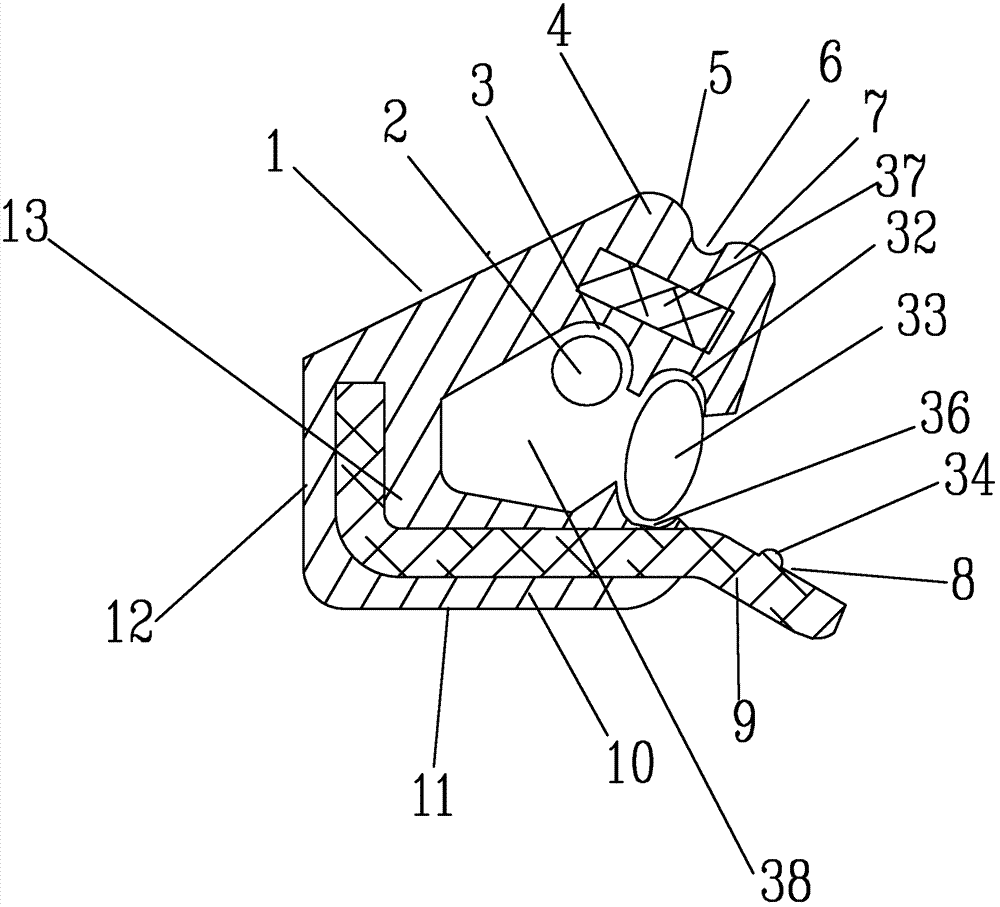

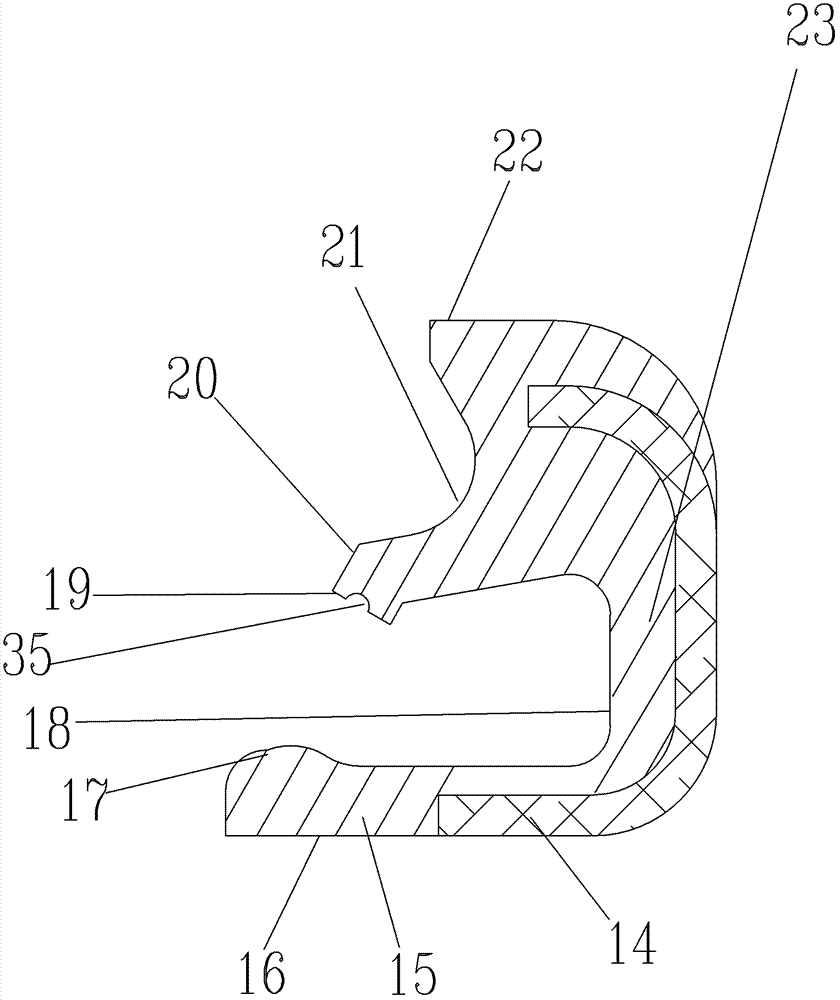

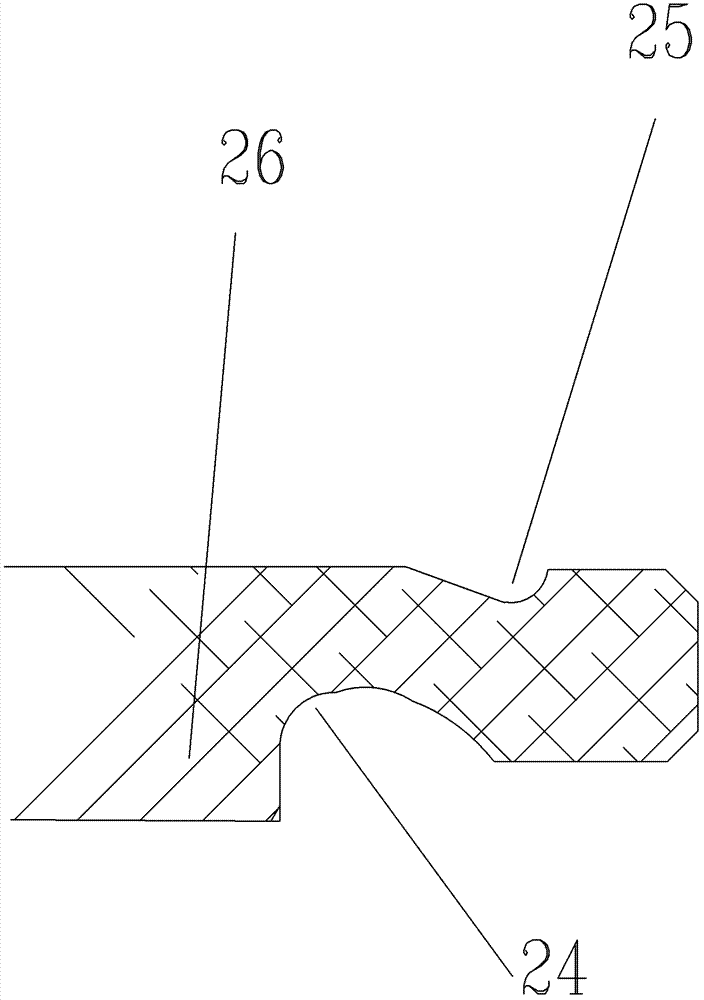

[0038] Embodiment: A universal joint capable of compensating for wear of a sealing device in this embodiment. like figure 1 , Figure 4 As shown, the section of the oil seal ring is U-shaped, and the main lip 4 and the auxiliary lip 7 are arranged on the outer wall of the inwardly bent section of the inner half arc 1 of the oil seal ring, and the main lip 4 and the auxiliary lip 7 are parallel to each other , The arc-shaped lip groove 6 is formed between the main lip and the auxiliary lip, and the edges of the main lip 4 and the auxiliary lip 7 are arc-shaped edges 5 . A balance frame 37 is embedded in the oil seal ring software 10 at the end of the inner half arc 1 of the oil seal ring. Inside the oil seal ring software between the spring groove 3 and the main lip 4. When the arc-shaped lip groove 6 is compressed by the spring ring 2 or the elastic ball 33, the pressure will first be transmitted to the balance skeleton 37, and then the force will go from the balance skelet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com