Tuyere arrangement device for preventing high temperature corrosion of water-cooled wall of garbage incinerator

A waste incinerator, high-temperature corrosion technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve problems such as high operating temperature, hazards, boiler explosion, etc., to improve temperature uniformity, expand the scope of influence, and improve temperature levels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

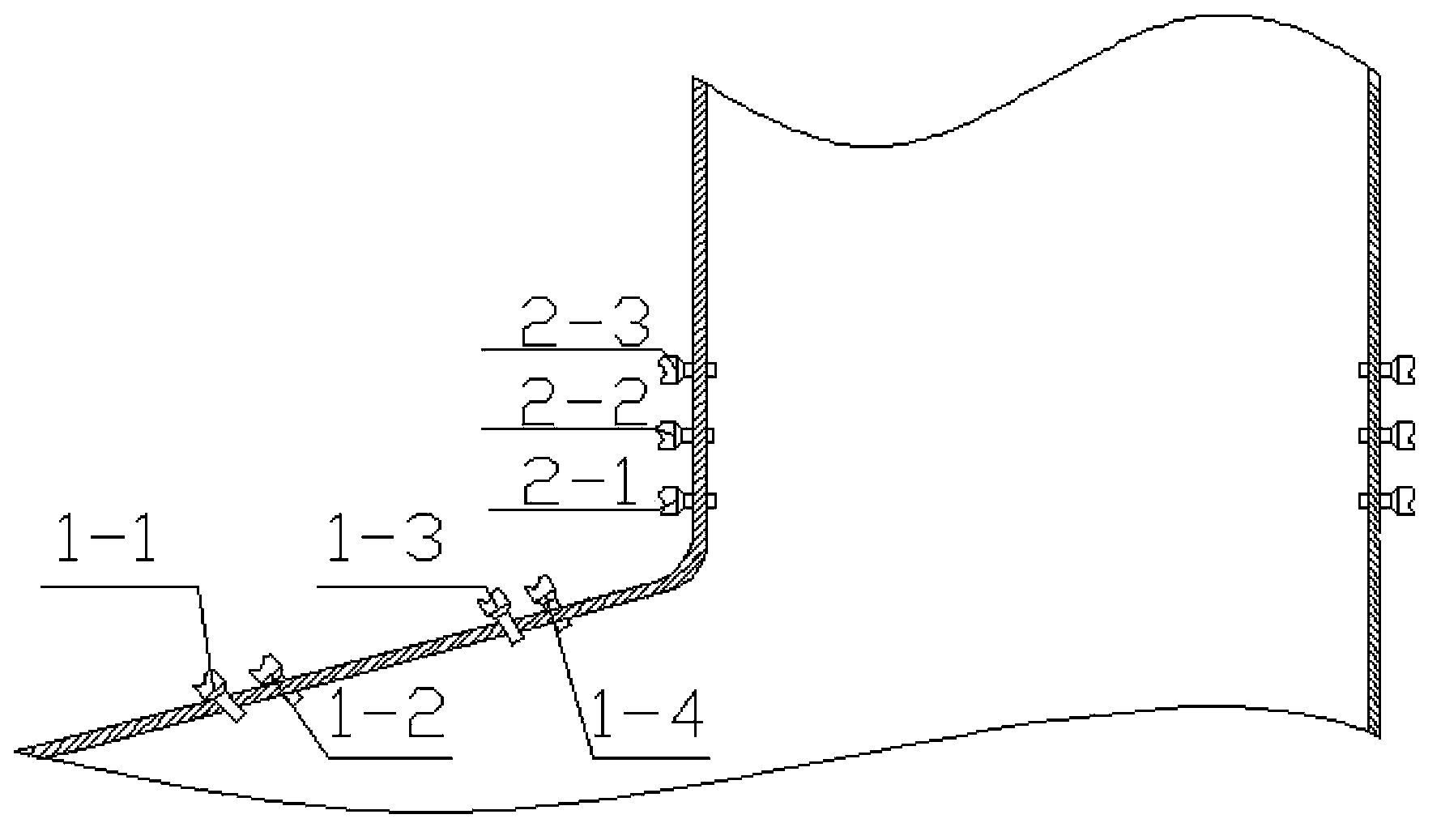

[0033] Such as figure 1 As shown, a tuyere arrangement device for preventing high-temperature corrosion of the water wall of a waste incinerator in the present invention includes a front arch and a furnace wall, and the front arch is sequentially provided with a first row of secondary tuyeres 1-1 and a second row of two along the direction of the furnace wall. Secondary air outlets 1-2, third row secondary air outlets 1-3, fourth row secondary air outlets 1-4;

[0034] Wherein, the horizontal distance between the first row of secondary air outlets 1-1 and the second row of secondary air outlets 1-2 is 0.2m~0.4m;

[0035] The horizontal spacing between the secondary air outlets 1-3 in the third row and the secondary air outlets 1-4 in the fourth row is equal to the horizontal spacing between the secondary air outlets 1-1 in the first row and the secondary air outlets 1-2 in the second row;

[0036] The distance between the secondary air outlets 1-3 in the third row and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com