Method for actively controlling frost heaving deformation of underground heat exchange pipe

An underground heat exchange tube and deformation control technology, applied in geothermal power generation, heat pump, refrigerator and other directions, can solve the problems of increasing the internal pressure of the heat exchange tube, reducing the service life and harm of the buried tube, and achieving the reduction of frost heave, Avoid the effect of frost heave deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

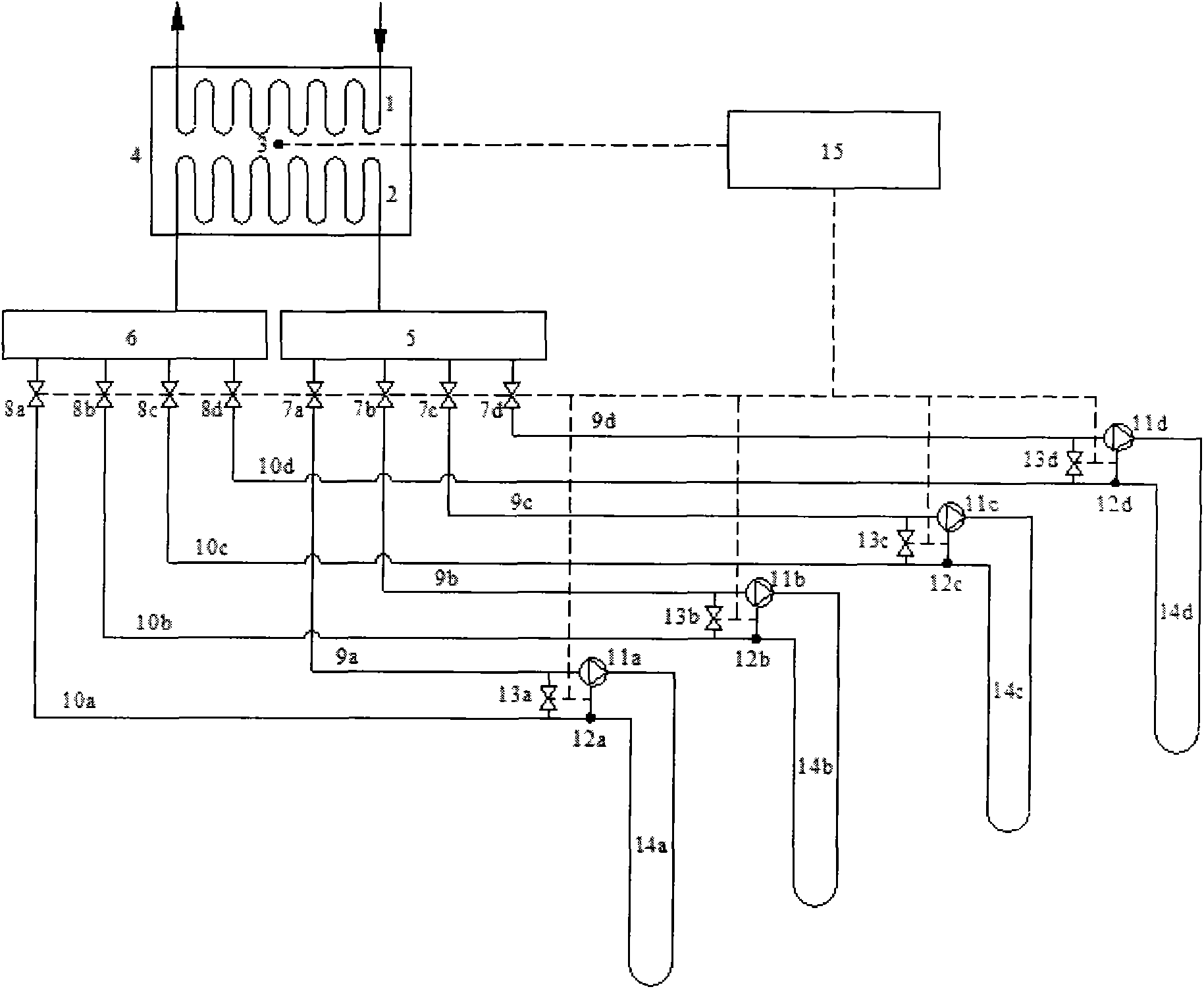

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0011] Such as figure 1 As shown, the frost heave deformation control system of underground heat exchange pipes includes heat absorbing coil 1, heat releasing coil 2, water tank temperature sensor 3, energy storage water tank 4, water separator 5, water collector 6, first water supply valve 7a, the second water supply valve 7b, the third water supply valve 7c, the fourth water supply valve 7d, the first water return valve 8a, the second water return valve 8b, the third water return valve 8c, the fourth water return valve 8d, the first Water supply pipe 9a, second water supply pipe 9b, third water supply pipe 9c, fourth water supply pipe 9d, first return water pipe 10a, second return water pipe 10b, third return water pipe 10c, fourth return water pipe 10d, first circulation pump 11a, the second circulation pump 11b, the third circulation pump 11c, the fourth circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com