Method of solving frost heaving of buried pipeline through forced ventilation

A technology of buried pipelines and forced ventilation, which is applied in pipeline heating/cooling, general water supply saving, pipes/pipe joints/fittings, etc. It can solve the problems of limited function, limited upstream and downstream pressure adjustment, and difficulty in grasping the time and degree of frost heave and other problems to achieve the effect of increasing the temperature and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

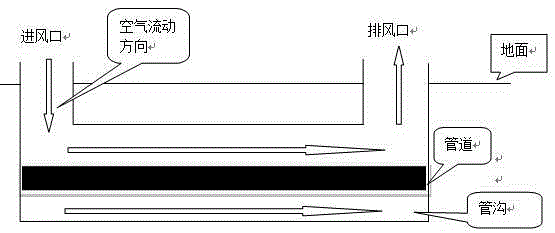

[0019] exist figure 1 In the process, a waterproof pipe ditch is built around the natural gas pipeline, the pipe is elevated, and then a fan is used to send air into one end of the pipe ditch through the air inlet and exhaust it at the other end.

[0020] The pipe trench can be built with waterproof cement or waterproof membrane to prevent groundwater or rainwater from entering the pipe trench.

[0021] The air inlet and exhaust outlet should prevent rainwater from entering, and the outlet can be downward or horizontal or equipped with a rainproof cap.

[0022] In order to prevent the air from flowing through the trench, the temperature drops too fast and the temperature at the outlet is too low, the air flow in the trench is adjusted according to the outlet temperature.

[0023] In order to prevent water accumulation in the pipe ditch, a water accumulation ditch should be set under the pipe ditch, and the water in the accumulation water ditch will flow into the water accumul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com