Supercritical fluid drying device and application method thereof

A technology of supercritical fluid and drying device, applied in drying gas arrangement, heating device, local stirring dryer, etc., can solve the problem of volume expansion being damaged by the microstructure of the drying material, and achieve excellent drying effect, miniaturization of the device, and operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

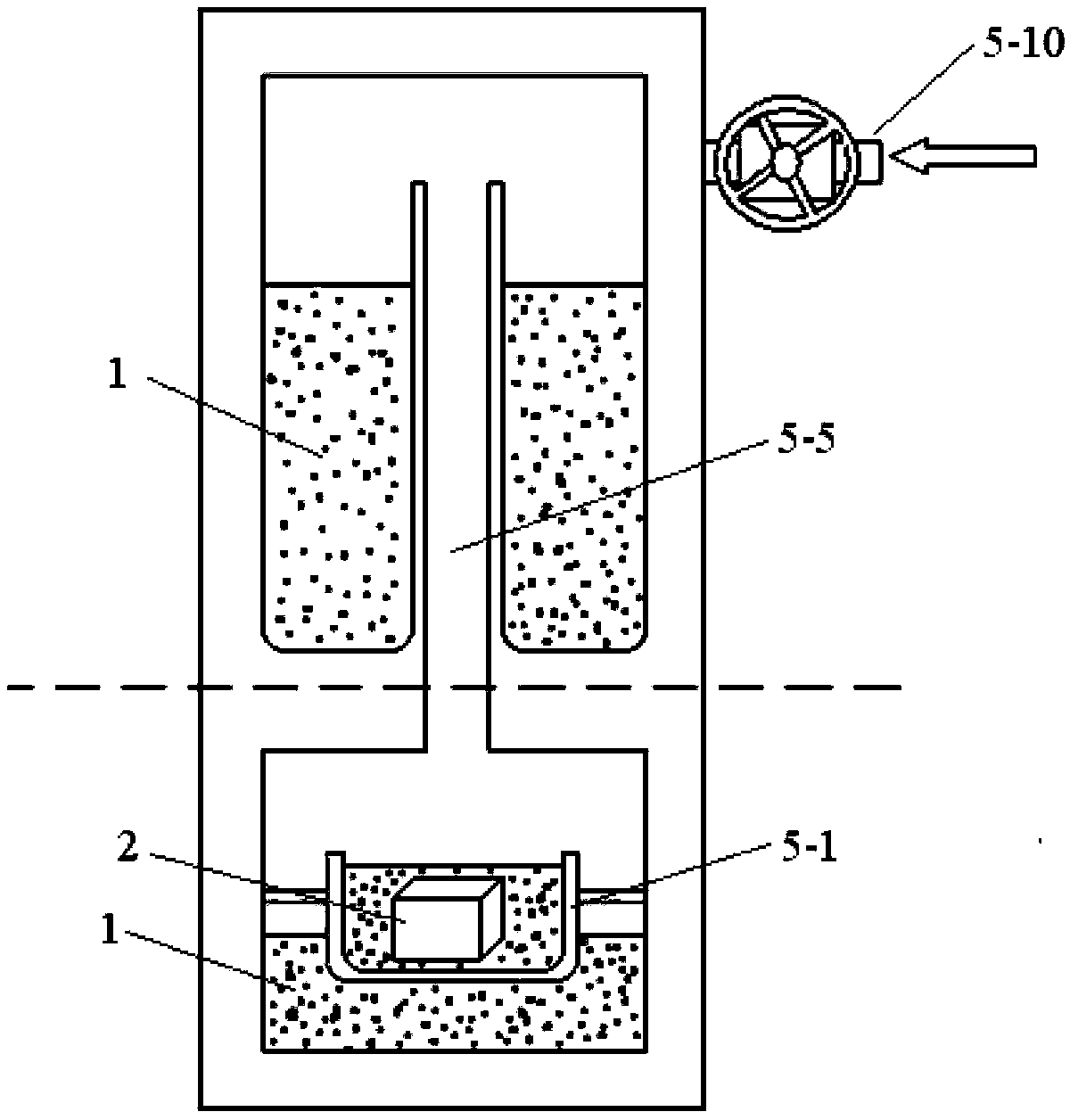

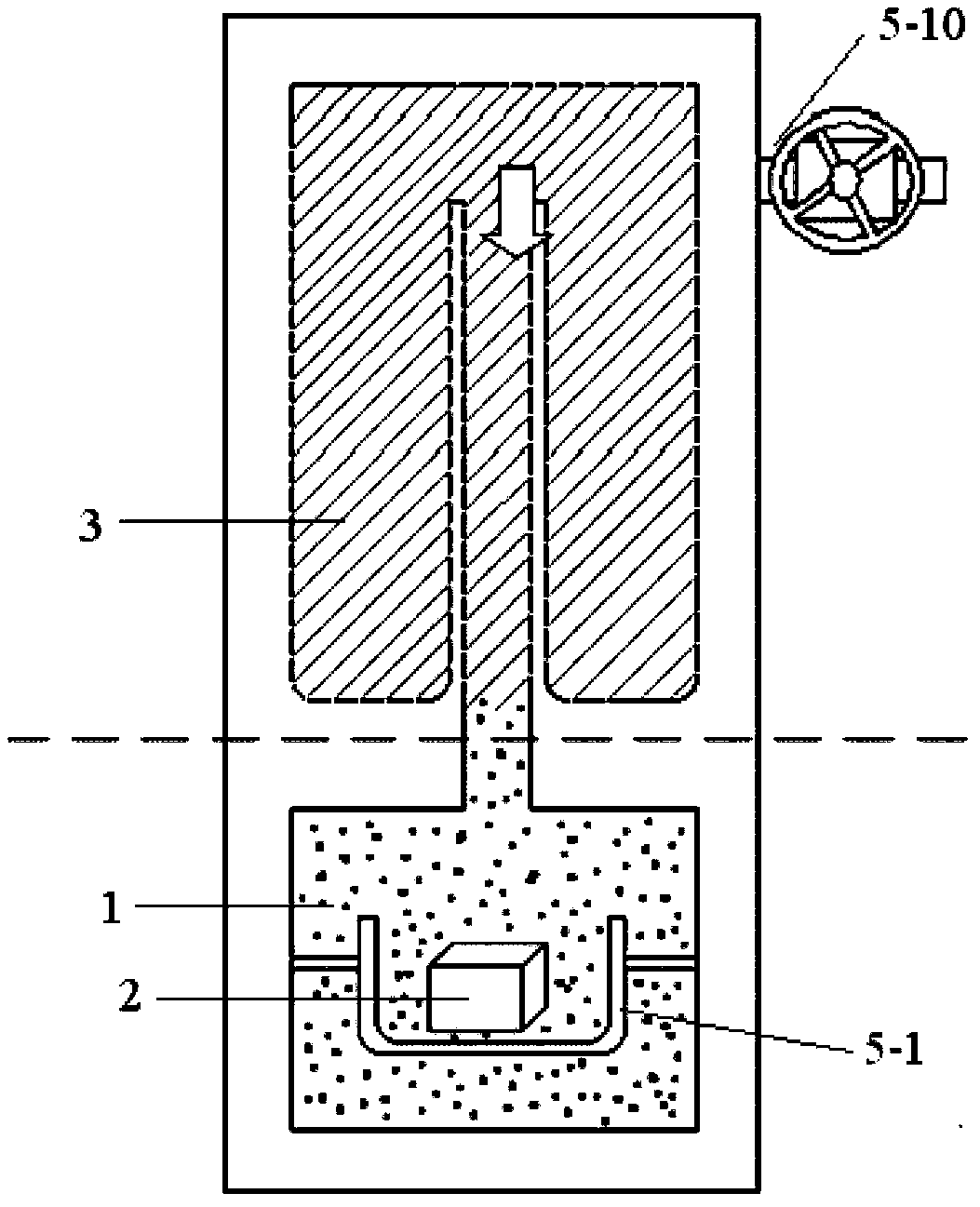

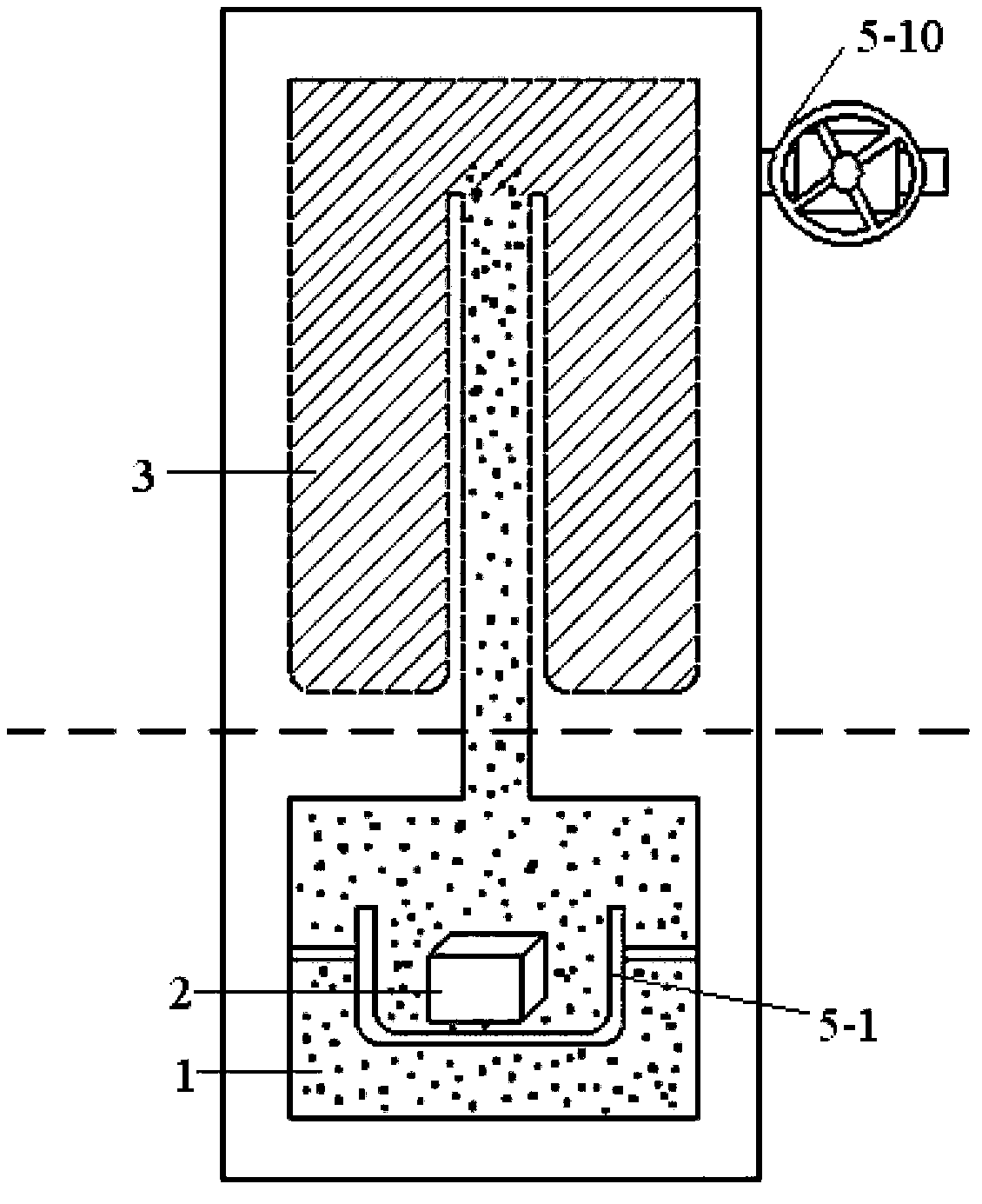

[0034] Specific embodiment one: a kind of supercritical fluid drying device of this embodiment, it comprises heating device and drying kettle 5; The nozzle 4, the cooling area 6, the heating jacket 7, the heat insulation layer 8 and the constant temperature oil area 9; the drying kettle 5 is composed of an upper chamber 5-6, a lower chamber 5-2, and a flange interface 5-8 , intake valve 5-10, outlet valve 5-11 and pressure gauge 5-12;

[0035] The lower chamber 5-2 is provided with a sample stage 5-1, and the outer surface of the chamber housing of the upper chamber 5-6 is provided with a mechanical seal covering layer 5-3, an annular heat insulating layer 5-4, and a communication Tube 5-5, hollow plunger lower part 5-7 and hollow plunger upper part 5-9, wherein, the upper chamber 5-6 is connected to the lower chamber through the hollow plunger lower part 5-7 and the annular heat insulation layer 5-4 5-2 for separation, the annular heat insulation layer 5-4 is located at the ...

specific Embodiment approach 2

[0041] Specific embodiment two: the using method of a kind of supercritical fluid drying device of present embodiment is carried out according to the following steps:

[0042] 1. Put the material to be dried into the sample table 5-1, inject the drying medium into the upper chamber 5-6 and seal it, open the inlet valve 5-10, close the outlet valve 5-11, and pass through the inlet valve 5- 10 Continuously fill inert gas into the drying kettle 5 to make the pressure inside the drying kettle 5 reach 8-9 MPa, close the inlet valve 5-10, and then use the heating jacket 7 to heat the upper chamber at a heating rate of 3-5°C / min. The chamber 5-6 is continuously heated to keep the temperature of the upper chamber 5-6 greater than 1.4 times the critical temperature of the drying medium. 2 Carry out continuous heating to keep the temperature in the lower chamber 5-2 lower than the critical temperature of the drying medium. After the pressures in the upper chamber 5-6 and the lower chamb...

specific Embodiment approach 3

[0049] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the drying medium in step 1 is liquid carbon dioxide or methanol. Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com