Adjustable weld inspection guided wave probe and use method thereof

An adjustable and receiving probe technology, which is applied in the field of guided wave probes for ultrasonic detection of weld defects and probes for non-destructive testing of welds. The effect of reducing the detection blind area, improving the detection accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

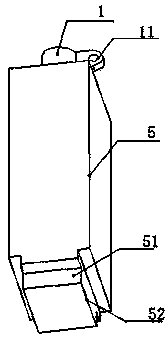

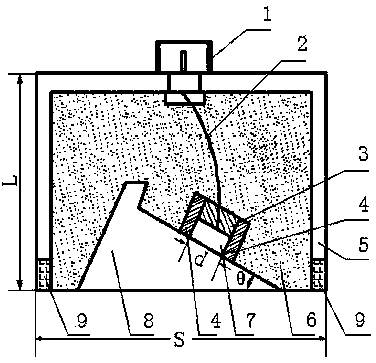

[0035] The transmitting probe and receiving probe articulated by the detachable hinge 11 are horizontally arranged side by side with an adjustable angle, and the surface of the weld 21 to be inspected connecting two metal plates 20 is coated with a viscous couplant, and the transmitting probe and receiving probe respectively pass through the strip at the bottom. The magnets 9 are laterally side by side and adsorbed and fixed on the weld seam to be inspected. By accurately adjusting the included angle α between the transmitting probe and the receiving probe, which is less than or equal to 15°, the best coupling between the wider weld seam 21 and the transmitting probe and the receiving probe can be realized.

Embodiment 2

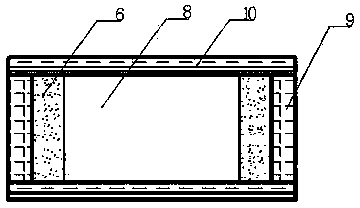

[0037]The transmitting probe and the receiving probe are arranged longitudinally front and back, the surface of the weld 21 to be inspected connecting two metal plates 20 is coated with a viscous couplant, and the two adjustable guided wave probes for weld seam flaw detection are respectively adsorbed longitudinally front and back by the strip magnet 9 at the bottom It is fixed on the weld seam 21 to be inspected. This allows an optimal coupling to the invention for narrower welds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com