Photoelectric composite cable

A photoelectric composite and cable technology, applied in communication cables, cables, optics, etc., can solve the problems of increased signal transmission loss, large cable diameter, and increased cable bending rigidity, so as to suppress the application of external force and achieve smooth wiring. , the effect of good transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

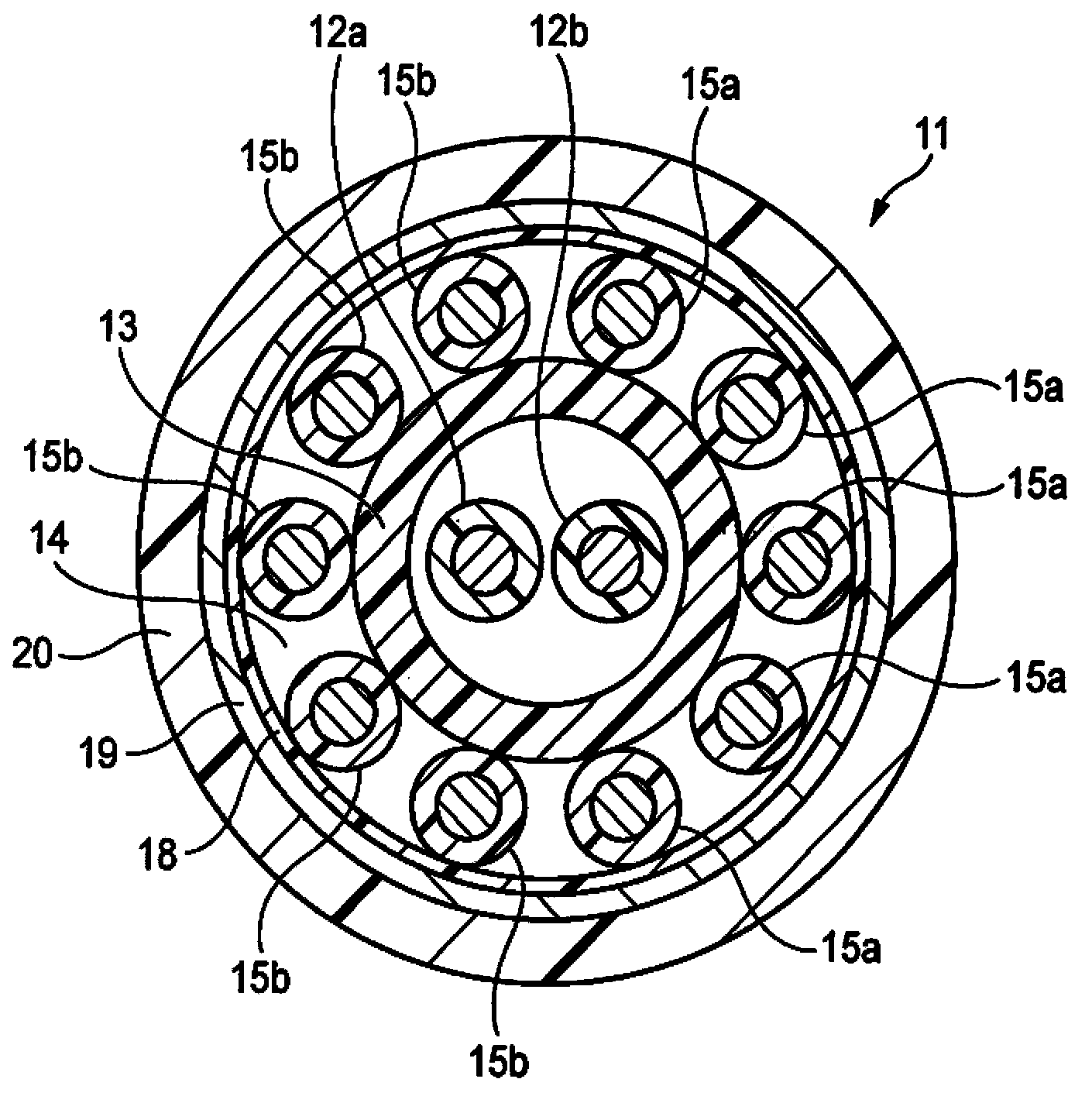

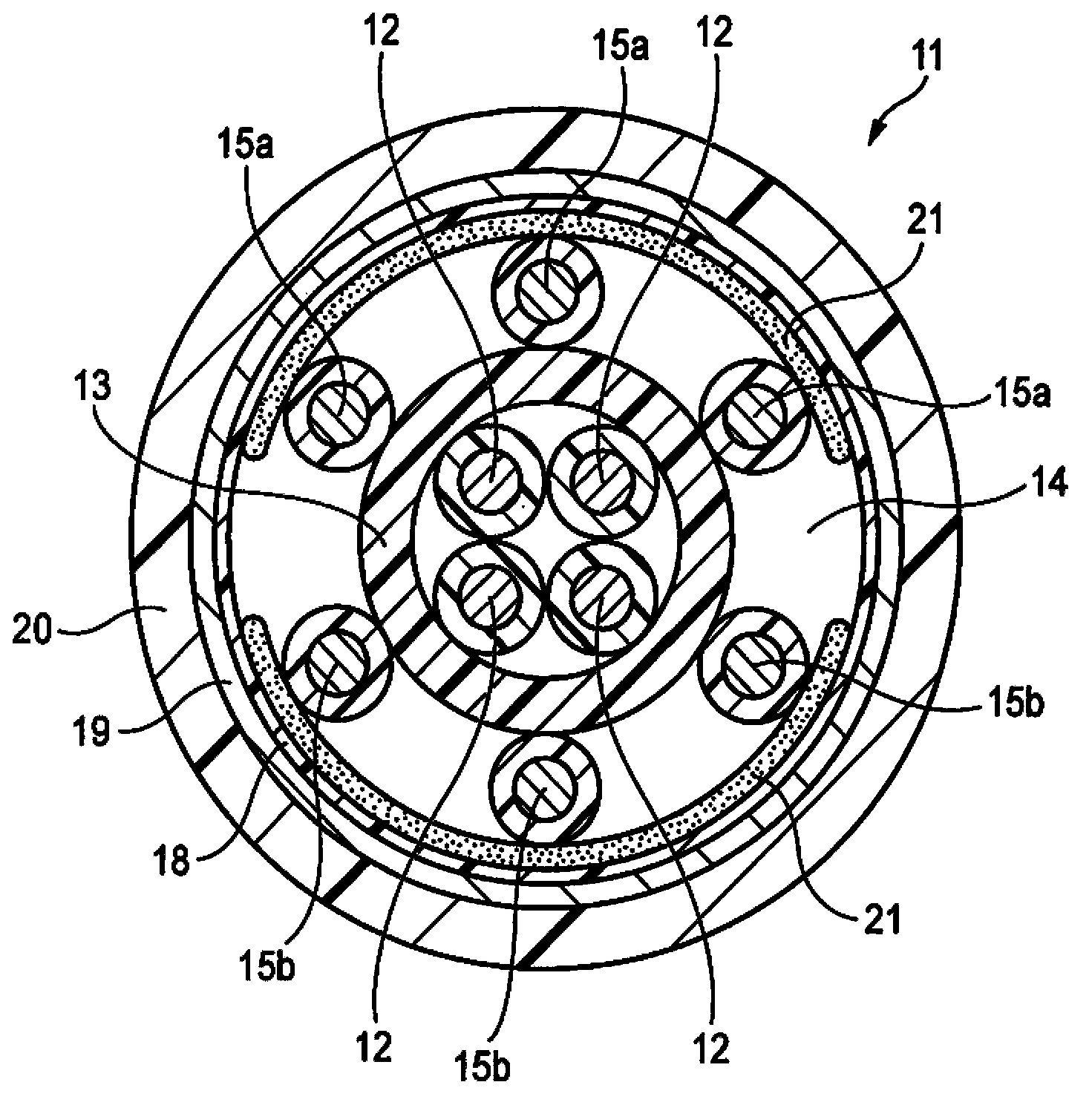

[0020] Hereinafter, an example of an embodiment of the photoelectric composite cable according to the present invention will be described with reference to the drawings.

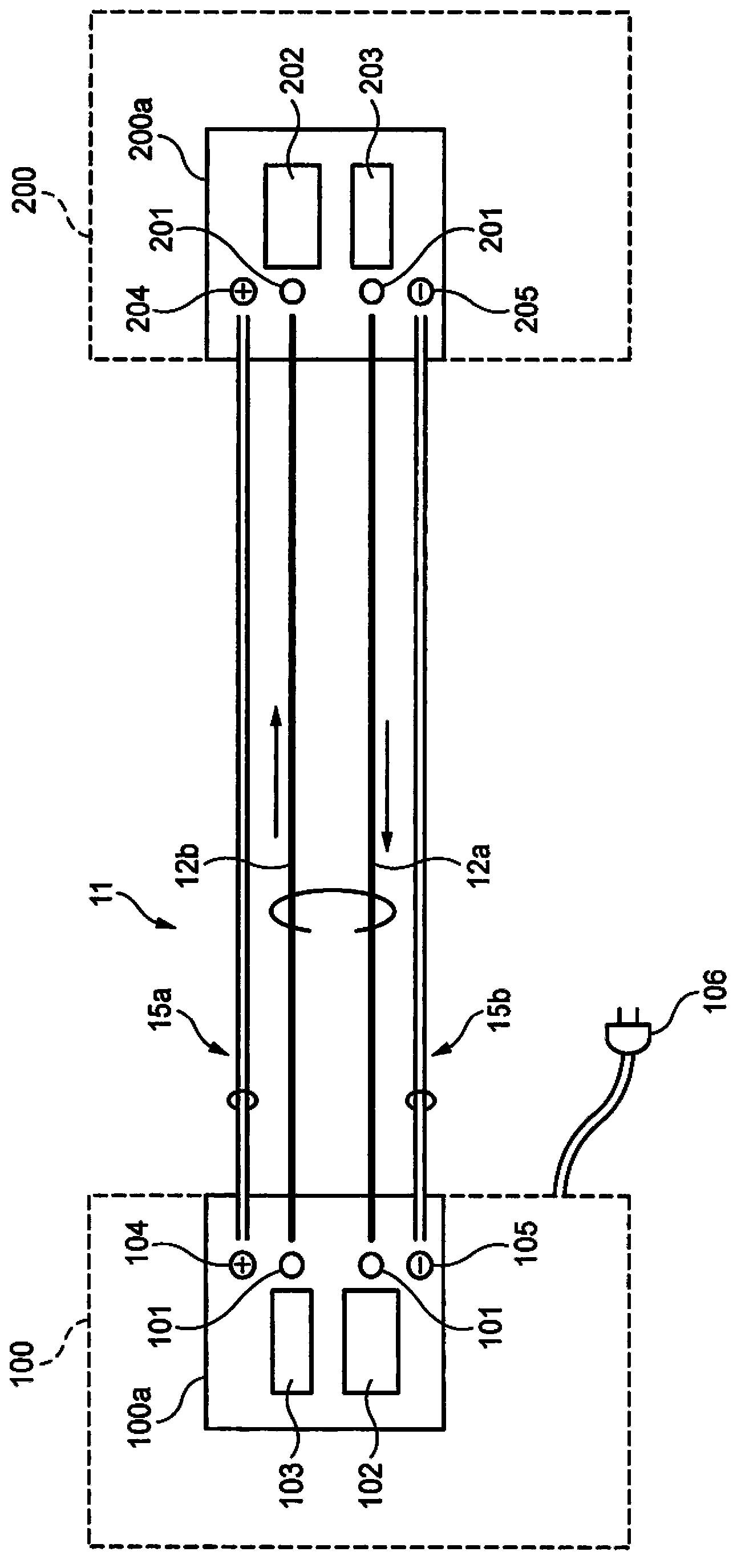

[0021] figure 1 It is a schematic diagram for explaining a state in which the personal computer 100 and the power supply hard disk 200 are electrically and optically connected through the photoelectric composite cable 11 as an example of using the photoelectric composite cable 11 . Such as figure 1 As shown, the photoelectric composite cable 11 connects the personal computer side connector 100a (an example of a connector) and the hard disk side connector 200a (an example of a connector), wherein the personal computer side connector 100a and the personal computer 100 The cable connection portion is connected, and the hard disk side connector 200 a is connected to the cable connection portion of the power supply type hard disk 200 .

[0022] The connector 100a on the personal computer side has: a light recei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com