Marine large-capacity main distribution board control screen

A main switchboard, large-capacity technology, applied in the direction of electrical components, supervision desk/panel, substation/switchgear cooling/ventilation, etc., can solve the problem of high degree of automation, low space utilization rate, main switchboard Problems such as the large capacity of the distribution board achieve good application prospects, high social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

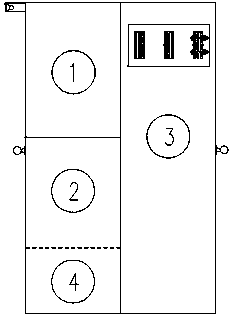

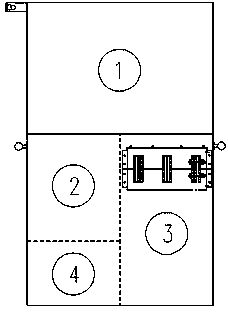

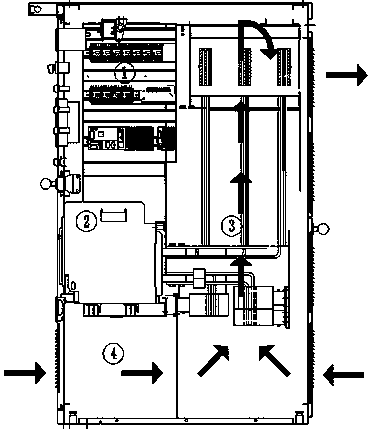

[0020] In the design of the control panel of the large-capacity main switchboard for ships of the present invention, the internal space is divided into front and rear parts in the traditional switchboard, such as figure 1 The distribution diagram of the traditional main switchboard control panel and image 3 The schematic diagram of the heat dissipation path of the control panel of the traditional main switchboard is shown. The main heating components bus bar and current transformer are placed in the rear part ③ of the cabinet body, where the bus bar is placed at the upper rear end of the cabinet body, and the upper part ① of the cabinet body is placed Measuring instruments, changeover switches, button indicator lights, control equipment, etc., ②place the circuit breaker, ④place the external wiring terminal block, and the heat dissipation methods are as follows: image 3 As shown by the arrow, the heat dissipation channel is led from the front and rear louvers at the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com