Method for producing a grain-oriented electric strip

An electrical steel strip, grain orientation technology, applied in transformer/inductor parts, inductor/transformer/magnet manufacturing, circuits, etc., can solve problems such as failure, and achieve the effect of small toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Embodiment 1: the impact of chromium nitrate on chemical action in phosphate solution

[0106] The following phosphate solutions were prepared.

[0107]

[0108] Table 4

[0109] The chromium(VI)-free and acid etch inhibitor-free phosphate / silica sol mixtures according to document WO 2009 / 101129 show a clearly prominent interaction with free iron surfaces. An even more significantly enhanced interaction was generated by the addition of chromium(III) nitrate. The combination of the additives chromium(III) nitrate and diethylthiourea (DETH) resulted in a clear inhibition of the chemical action.

[0110] The inhibition of the chemical action allows the use in industrial coating plants, since contamination of the phosphating solution by iron ions is prevented.

[0111] Figure 10 The effect of chromium(III) nitrate and diethylthiourea (DETH) on the acid etching reaction of iron surfaces is shown.

Embodiment 2

[0112] Example 2: Influence of chromium nitrate in the insulating solution according to the invention on colloidal stability

[0113]

[0114]

[0115] table 5

[0116] Time curve measurements of the viscosity of the insulating solution at 50°C were carried out. Figure 11 Results are shown.

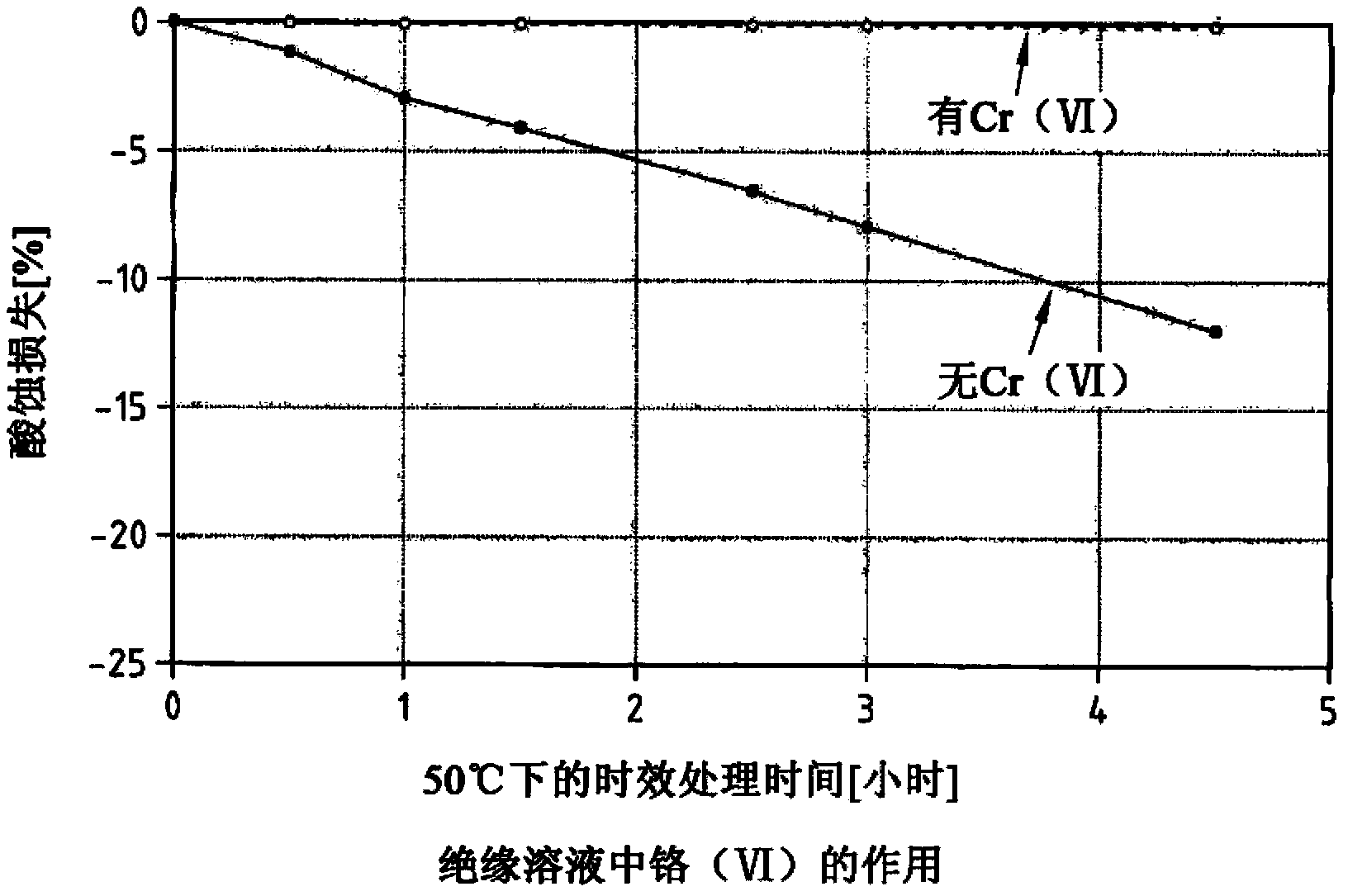

[0117] Insulating solutions with chromium(VI) show excellent solution stability. Removal of chromium(VI) compounds (solution 1) without any alternative measures resulted in a drastic deterioration of the solution stability, which made its use in industrial manufacturing processes impractical. Replacing chromium (VI) with chromium (III) also leads to a deterioration of solution stability. Like solution 1, such a solution is also unsuitable for practical use. However, if chromium(III) is used in the solution containing the colloidal stabilizer (A), the solution stability is maintained. Such solutions are suitable for use in industrial manufacturing processes.

Embodiment 3

[0118] Embodiment 3: the influence of the chromium nitrate in the phosphate solution on the tensile stress

[0119] Via the fired insulating layer, a tensile stress should be exerted on the ferromagnetic substrate, which should have a positive influence on the working structure and additionally reduce the alternating magnetization losses.

[0120] In order to demonstrate the advantages of the insulating solution according to the invention, the following solutions were formulated.

[0121]

[0122] Table 6

[0123] The solution was coated on a grain-oriented electrical steel strip with a size of 305 mm×60 mm, and fired at 850° C. for 2 minutes. In the fired state, the layer coating is always 3.5g / m 2 . Next, a tensile stress test is carried out. Figure 12 The results are summarized.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap