Mulberry leaf picking machine

A technology for picking mulberry leaves, which is applied in the field of electric mulberry leaf picking machines, can solve the problems of mulberry leaves not keeping up, low production efficiency of sericulture, and restriction of sericulture production efficiency, so as to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

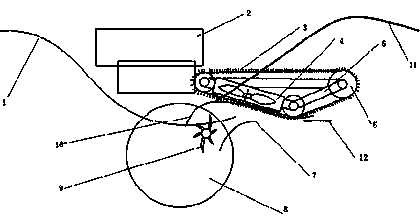

[0007] As shown in the figure: the storage battery driver 2 drives the wheel 8 to move forward, so that the concave S-shaped guide plate 1 overwhelms the mulberry branches and slides along the guide plate 1 to the place where the beating wheel 9 is housed in the middle of the guide plate; the beating wheel 9 is driven by the engine 2 Drive rotation, interrupt the mulberry leaf petiole on the mulberry plant that slides along guide plate 1, and be unlikely to break mulberry bud, mulberry bark; A low air pressure is formed, and the fallen mulberry leaves are sucked upward to the collection net 10. The roller 5 and the connecting rod 6 support the conveyor belt 3 with toothed nails to surround the collection fan 4. The roller 5 is driven by the storage battery driver 2, and the roller 5 drives the belt with toothed nails. Conveyor belt 3 runs fast, and transports mulberry leaves along upper collecting net 10 to leaf outlet 12; lower collecting plate 7 is a sealing plate, which is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com