High-speed rotary wheel for dispersion machine

A technology of high-speed rotation and dispersing machine, applied in the direction of mixer, mixer accessories, dissolution, etc., can solve the problem of slurry temperature rise and achieve the effect of preventing excessive temperature rise and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

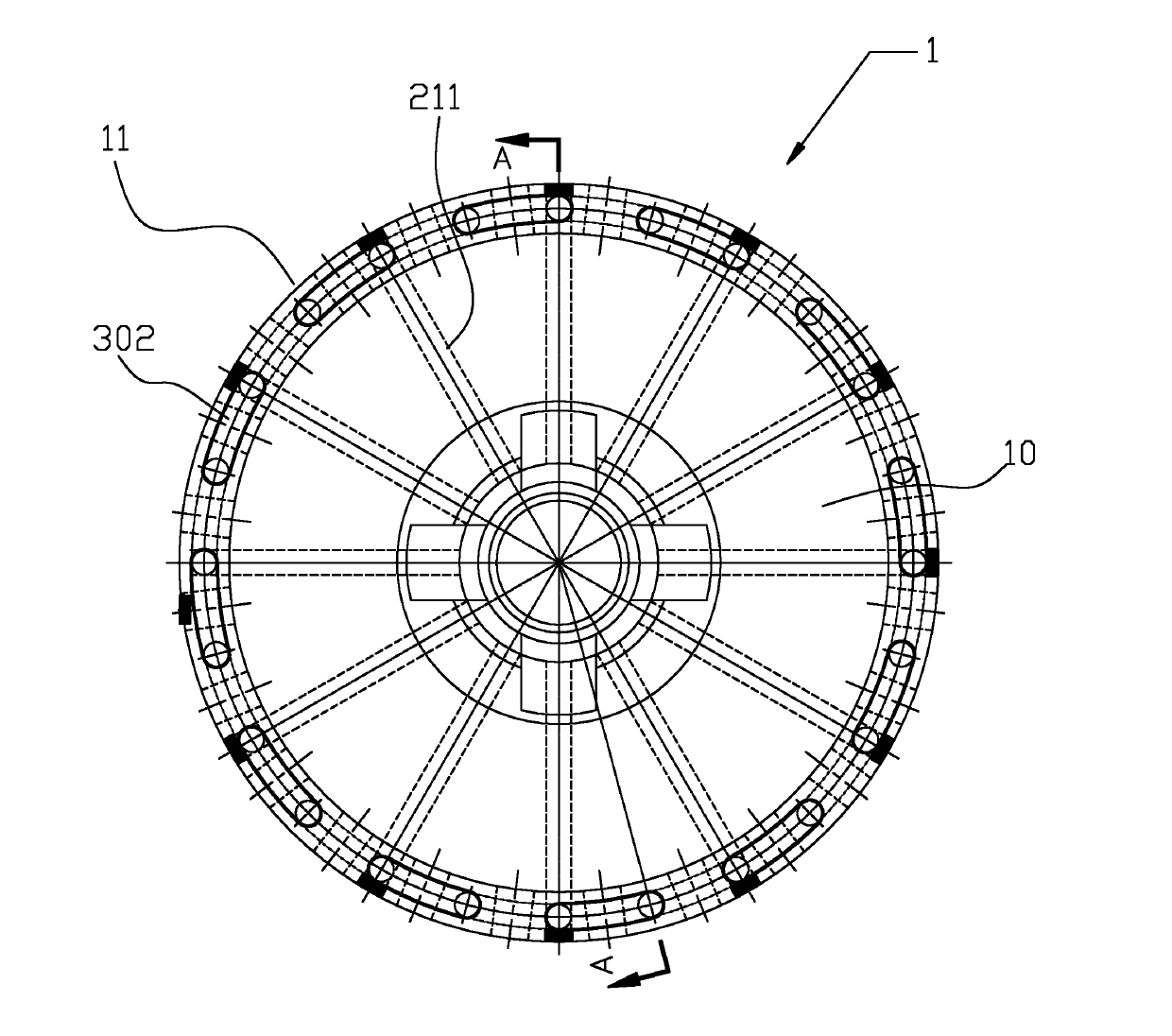

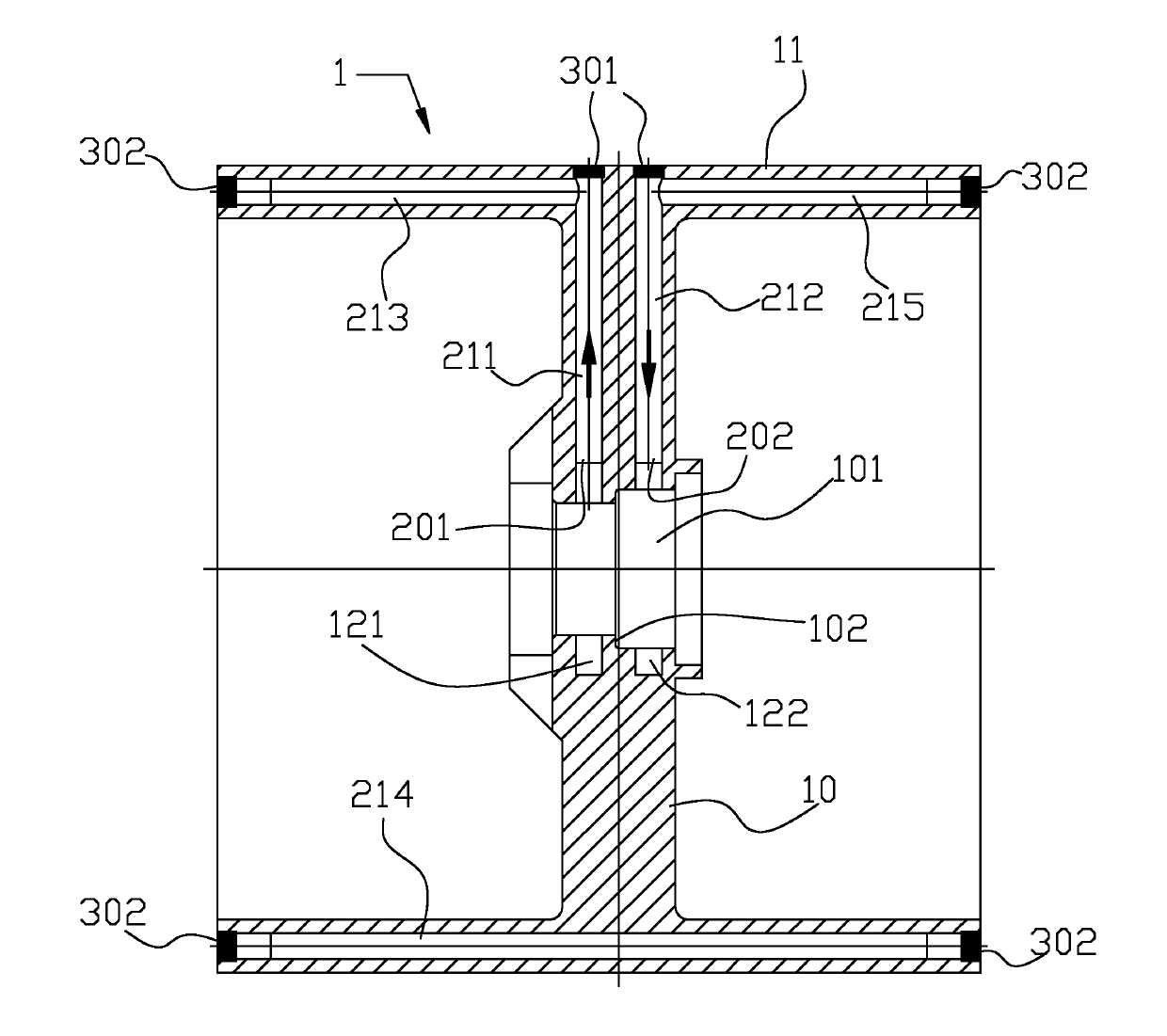

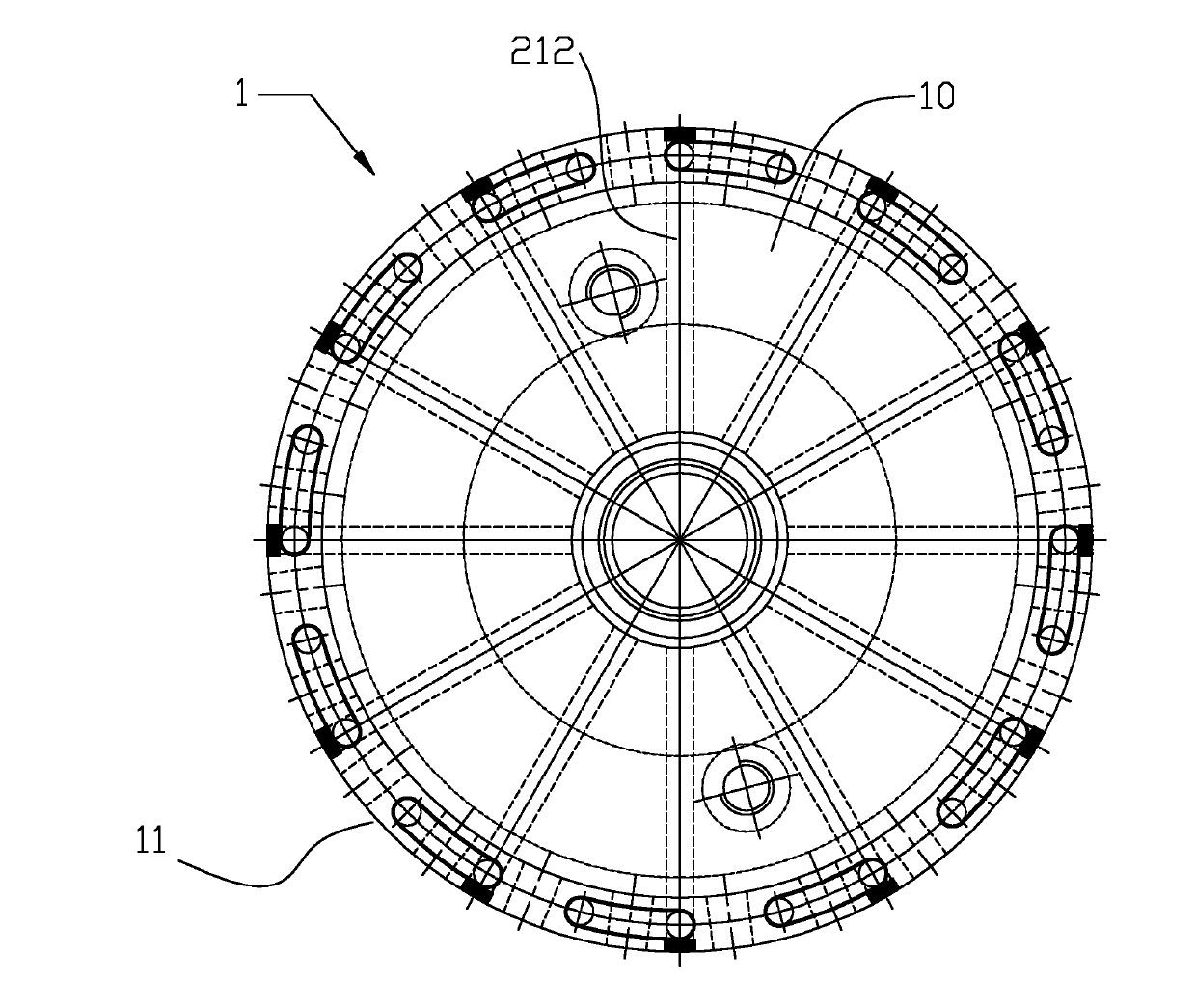

[0020] The high-speed rotating wheel used in the disperser of the present invention is installed on the drive shaft of the disperser, and rotates at a high speed driven by the drive shaft to disperse the slurry. In the invented high-speed rotating wheel for the disperser, in order to solve the problem of excessive temperature rise caused by friction with the slurry when the high-speed rotating wheel rotates at high speed, there is at least one coolant supply inside the high-speed rotating wheel Through the cooling channel, when the high-speed rotating wheel rotates at high speed, the coolant can be used to pass through the cooling channel to cool the high-speed rotating wheel, and the slurry also exchanges heat with the high-speed rotating wheel to avoid excessive temperature rise of the slurry. The number of cooling passages inside the high-speed rotating wheel can be selected according to actual needs, and is not limited to one. Inside the rotating wheel, the coolant can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com