Rotary push-assisting type packaging bottle

A packaging bottle and boosting technology, which is applied in the field of packaging bottles for packaging paste-like or emulsion-like substances, can solve the problems of large space occupation, inconvenient use and storage, and easy pollution, so as to achieve uniform stress relief and no pollution. , to avoid the effect of overdose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

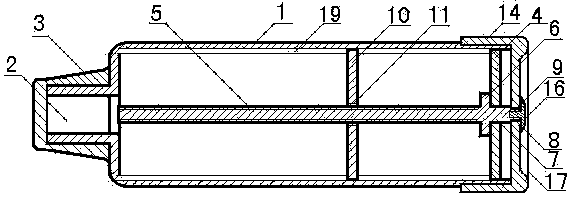

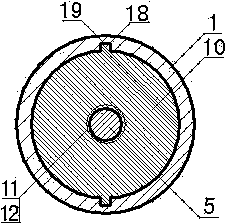

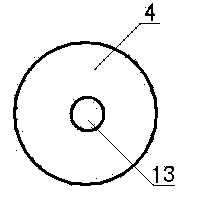

[0012] With reference to the drawings, the rotary booster packaging bottle includes a bottle body 1, a bottle mouth 2, a bottle cap 3, and a bottle bottom 4. The bottle body 1 is provided with a threaded rod 5, and the threaded rod 5 is provided with a blocking plate 6 to block The rear part of the plate 6 is a round shaft 7, behind the round shaft 7 is a square end 8, and a screw hole 9 is opened on the square end 8. A pushing plate 10 is fitted on the threaded rod 5, and a circular hole 11 is formed on the pushing plate 10, and the circular hole 11 is provided with a thread 12 matching the threaded rod 5, and the pushing plate 10 can move back and forth when the threaded rod 5 is rotated. The bottle bottom 4 and the bottle body 1 are fixed together, the bottle bottom 4 is provided with a shaft hole 13, and the round shaft 7 of the threaded rod 5 is inserted into the shaft hole 13 of the bottle bottom 4. The bottom 4 of the bottle is covered with a rotating sleeve 14. A square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com