Vane machine with axial and radial inlet/outlet

A mechanical and inlet technology, applied in the field of wing core machinery, can solve problems such as the limitation of the area and size of the outlet, and achieve the effects of enlarging the cross-sectional area, reducing the flow rate, and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

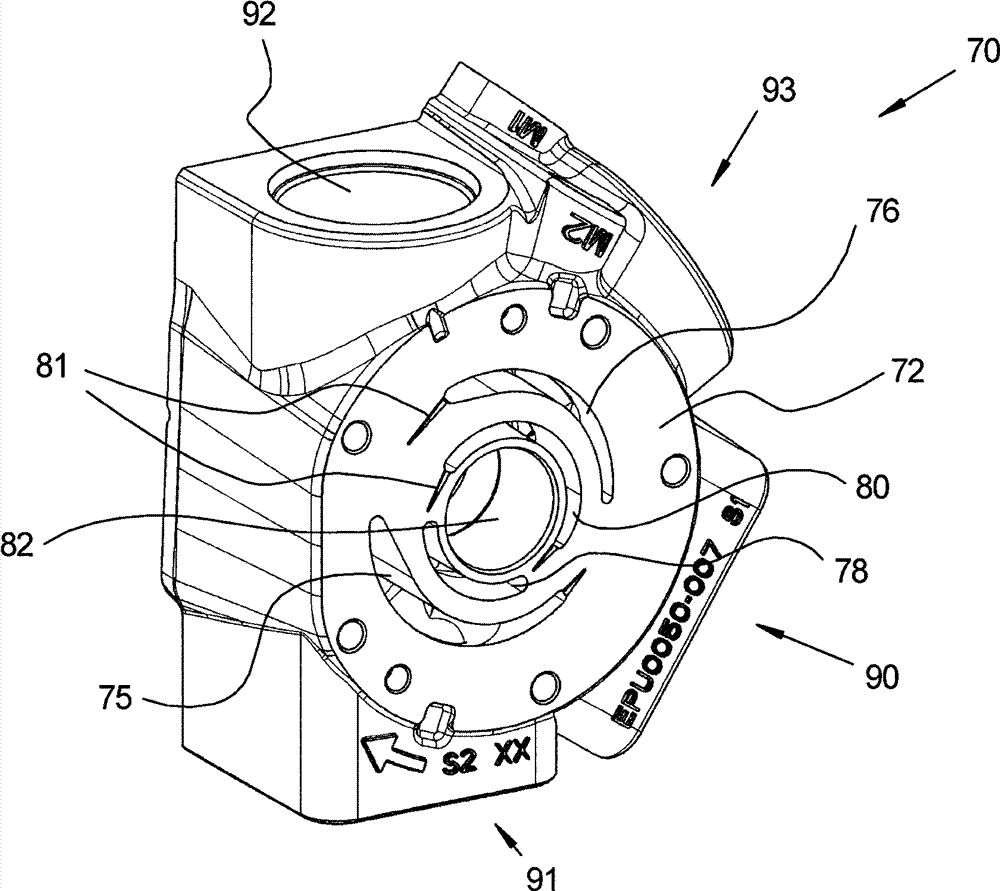

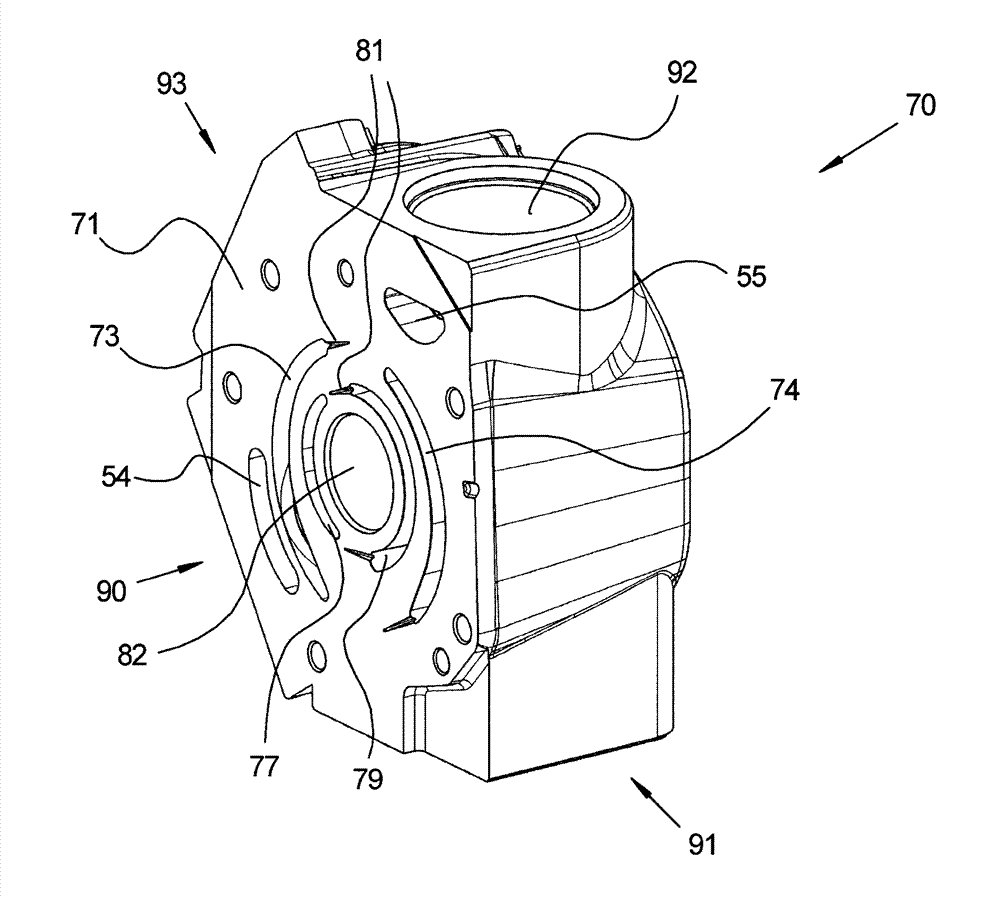

[0023] figure 1 Shown without control parts (in image 3 The perspective view in the case of reference number 70 ), so that the first rotor 32 can be seen. exist figure 2 relative to figure 1 Only the viewing direction is changed so that the second rotor 33 can be seen.

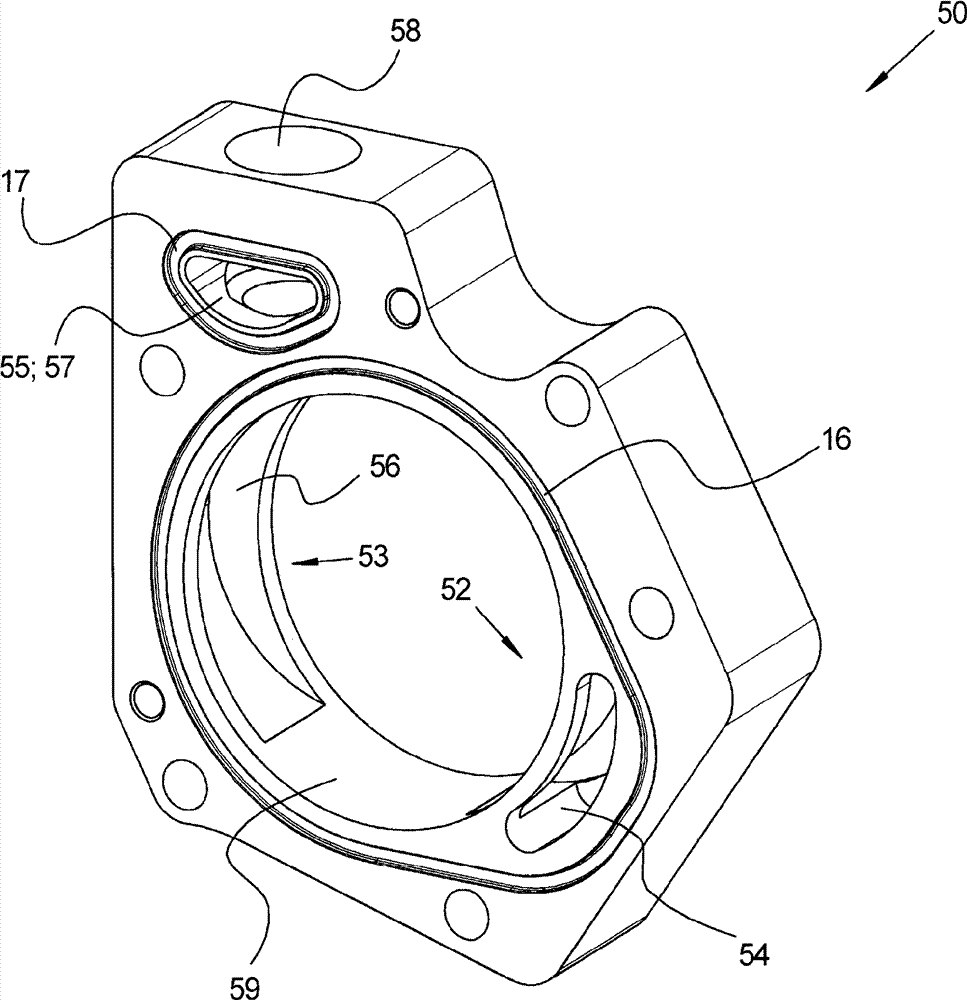

[0024] Described wing core machine 10 comprises housing 11, and this housing then comprises first locking plate 13, first cam part 50, control part (in image 3 Middle number 70), the second cam member 51 and the second lock plate 14 . The locking plate 13; 14 and the associated cam part 50; 51 are fixed on the control part with bolts 12.

[0025] A rotor shaft 30 is rotatably mounted in the housing 11 , protruding from the housing 11 with a drive journal 36 so that it can be brought into a rotational drive connection, for example, with an electric motor. . The swivel bearing is here in the control plate and is preferably designed in the form of a hydrodynamic slide bearing. The first locking plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com