Exhaust gas reducing apparatus

A technology of exhaust gas and exhaust gas filter, which is applied in the direction of exhaust device, silencer device, exhaust treatment, etc. It can solve the problems of unstable flame, difficult flame, difficult to effectively remove filter soot particles, etc., so as to ensure a stable rise Or be able to maintain and remove the effect of soot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

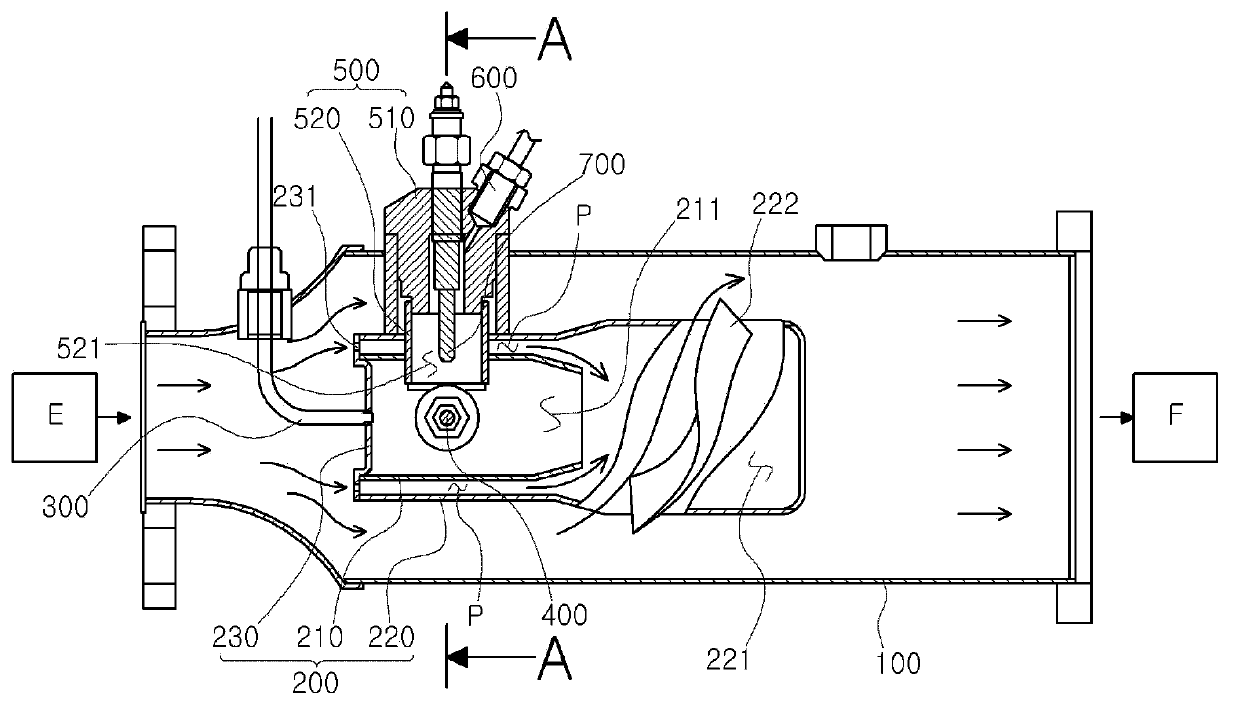

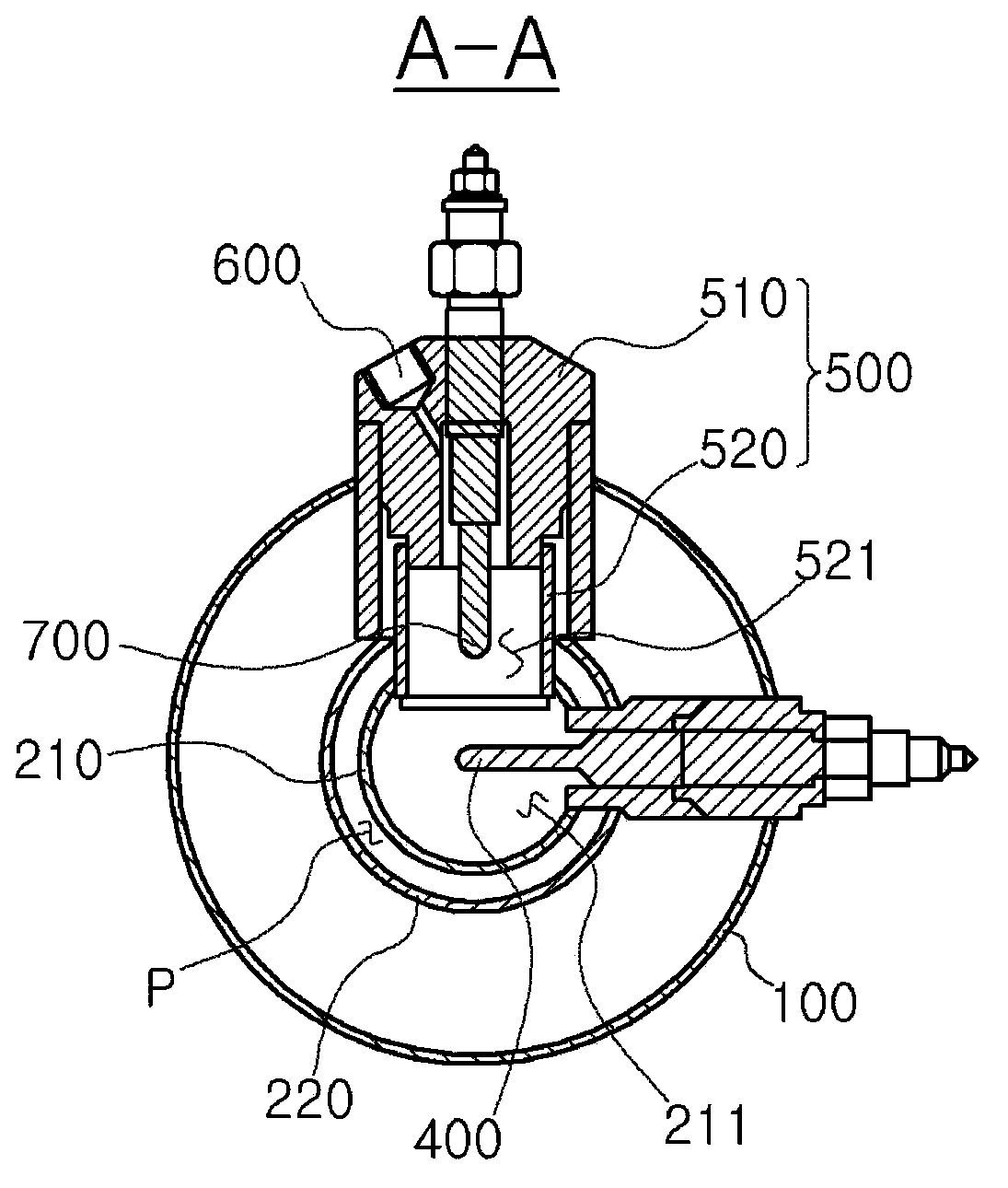

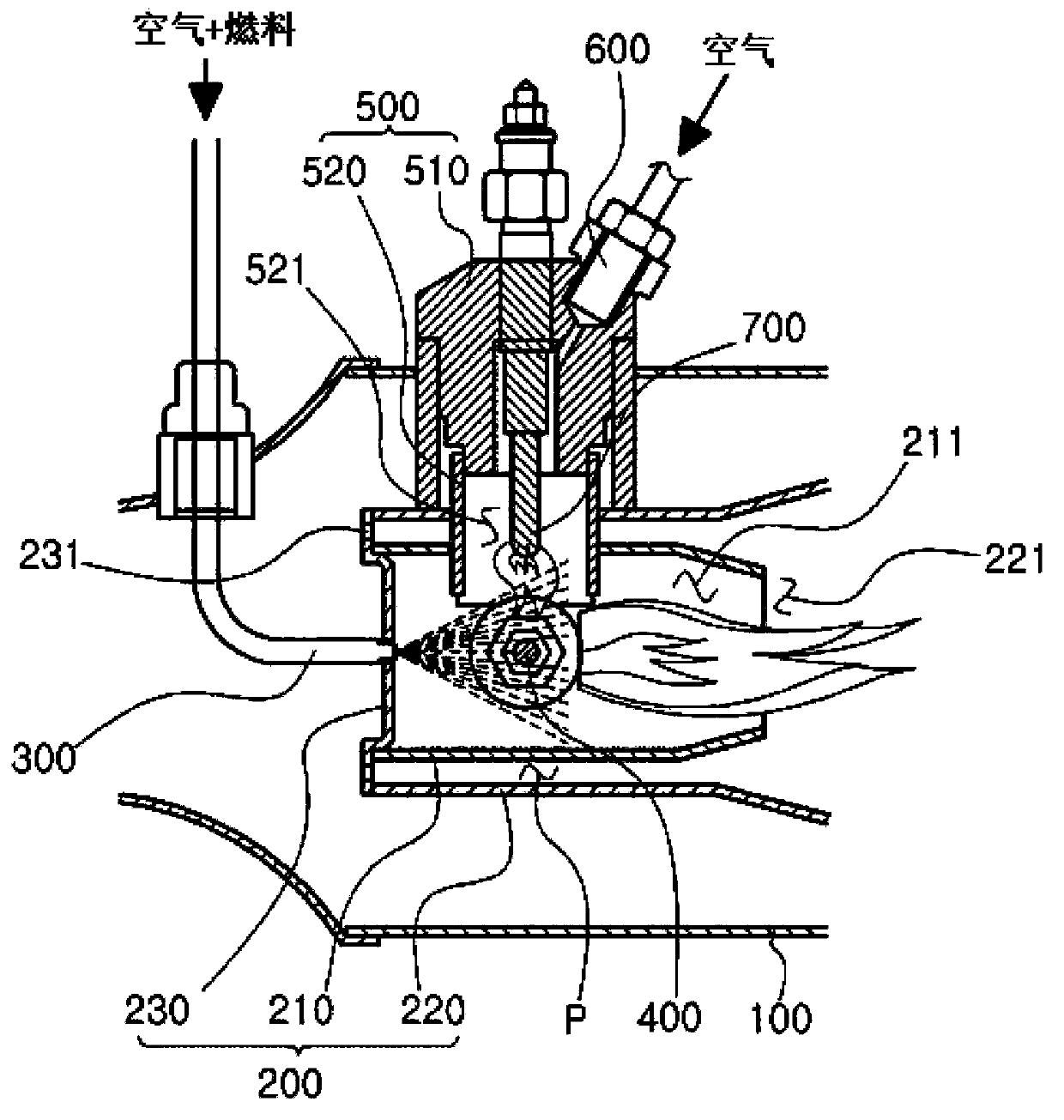

[0055] Such as figure 1 as shown, figure 1 is a cross-sectional view illustrating a cross-section of an exhaust gas reducing device according to an embodiment of the present invention; figure 2 yes figure 1 Sectional view of line A-A in middle; image 3 It is an enlarged view showing the first combustion part and the second combustion part of the exhaust gas reduction device according to the embodiment of the present invention; Figure 4 It is a diagram illustrating the operating state of the exhaust gas reduction device according to the embodiment of the present invention.

[0056] figure 2 In order to show the swirling body formed in the flame part, the partial section of the flame part is not shown; in figure 1 and Figure 4 In , the flow of exhaust gas is marked by arrows.

[0057] The tail gas reduction device of the embodiment of the present invention is as Figure 1 to Figure 4 As shown, it is composed of an exhaust pipe 100 , a first combustion unit 200 , a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com