Surface checking method of printed circuit board

A printed circuit board, surface inspection technology, used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of distinguishing copper surface from substrate, inability to detect conditions, and inability to inspect quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]

[0017] A method for surface inspection of a printed circuit board provided by the technical solution will be further described in detail below in conjunction with an embodiment

[0018] A method for surface inspection of a printed circuit board provided in this embodiment includes the following steps:

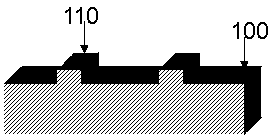

[0019] The first step is to scan the surface of the printed circuit board with laser to obtain the three-dimensional structure of the surface of the circuit board;

[0020] In this embodiment, the semi-finished printed circuit board (the inner layer circuit or the outer layer circuit has been produced) that needs to be inspected on the surface is placed on a flat table. A laser scanning system scans the surface of the circuit board in a non-contact manner. Laser systems can be designed using the principle of triangulation ranging. The image obtained by scanning is a three-dimensional image of the surface of the circuit board; the three-dimensional image mainly inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com