Core Passive Waste Heat Removal System after Accident of Large Pressurized Water Reactor Nuclear Power Plant

A pressurized water reactor nuclear power plant, passive waste heat technology, applied in nuclear power generation, reactors, nuclear engineering, etc., can solve problems such as core melting, Mark I unit can not realize core waste heat discharge, radioactive material leakage, etc., to reduce Effects of air resistance, increased air cooling capacity, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

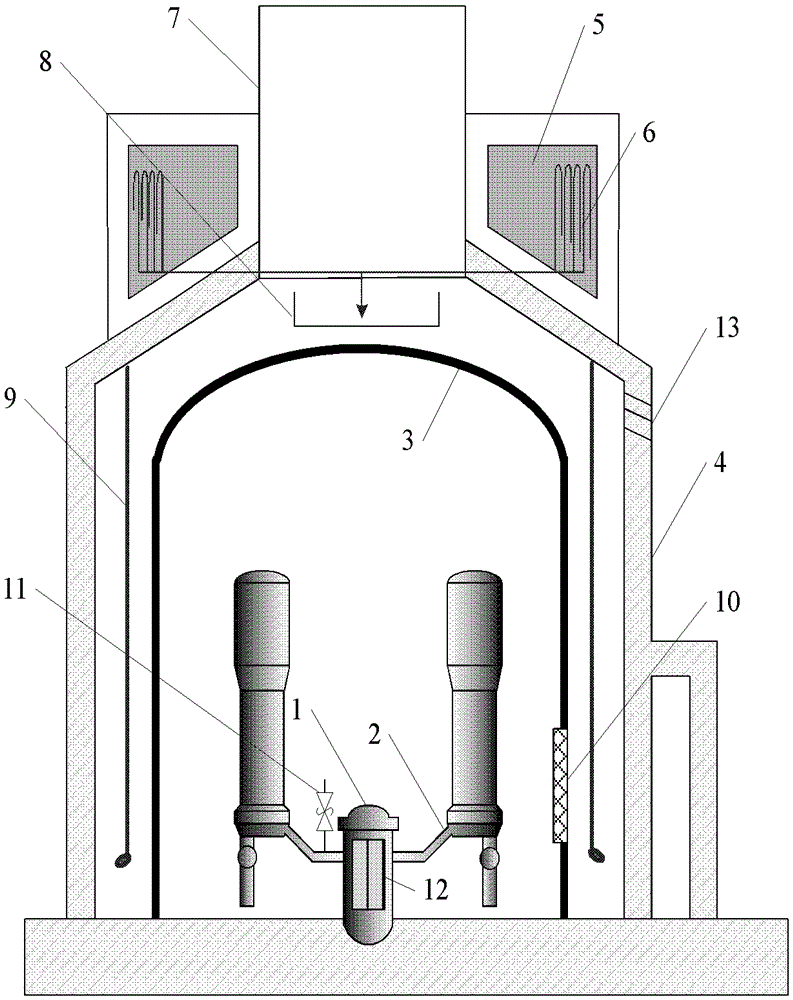

[0030] Such as figure 1 As shown, a completely passive cooling system for the core after an accident of a large pressurized water reactor nuclear power plant according to the present invention, in which the steel containment vessel 3 is set in the shielded building 4 of the steel-concrete composite structure. The steel containment vessel 3 has a thickness of 4-40 cm and can withstand a pressure of 0.2-2 MPa.

[0031] A chimney 7 is connected to the top air channel of the shielded factory building 4 , and the chimney 7 extends upwards out of the top of the shielded factory building 4 . A containment cooling water tank 5 is set outside the top of the shielded building 4 and around the chimney 7 , and two or three containment cooling water pipes 6 are set in the containment cooling water tank 5 . A cooling water distribution pan 8 is provided in the shielded building 4 , above the top of the containment vessel 3 and below the chimney 7 . The water inlet of each containment cool...

Embodiment 2

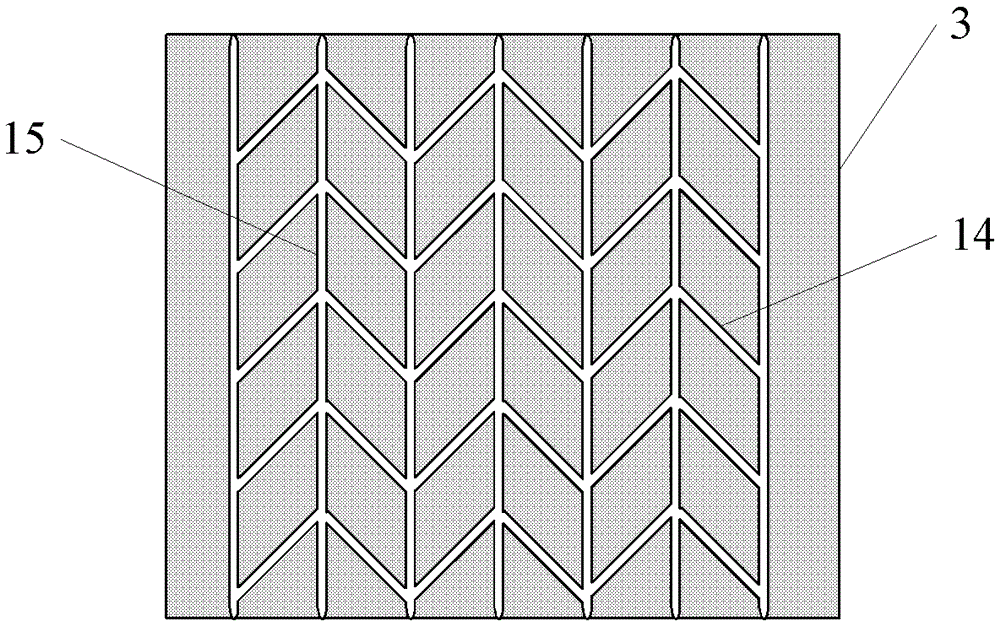

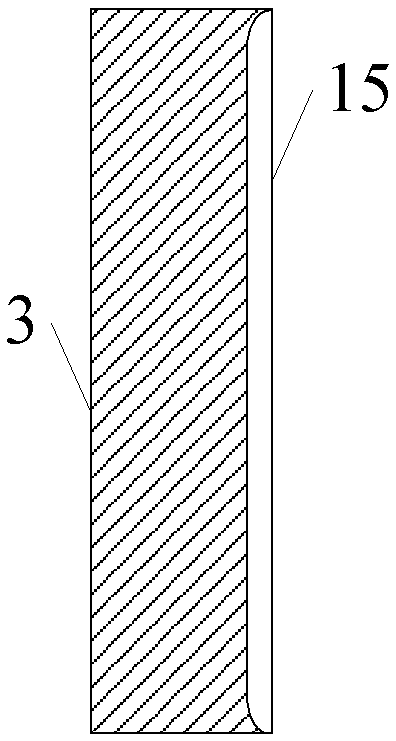

[0039] In Example 2, such as Figure 4 with Figure 5 As shown, the vertical section of the steel containment vessel 3 and the inner and outer walls of the dome are respectively welded and fixed with 100-3000 rows of ribs 17 , and the rest are the same as in Embodiment 1. The ribs 17 can be arranged in all ranges on both sides of the containment vessel, and the specific number depends on the inner and outer wall areas of the containment vessel 3 and the specific internal and external structures.

[0040] The ribs 17 and the containment shell 3 are made of the same material. The radial length of the fins 17 along the containment vessel is 10cm-200cm (for example: 10mm, 100mm or 200mm), and the thickness of the fins 17 is 0.1-1cm (for example: 0.1mm, 0.5mm or 1mm). The distance between adjacent row ribs 17 is 10cm-200cm (for example: 10mm, 100mm or 200mm).

Embodiment 3

[0042] In Example 3, 100 to 3000 rows of heat exchange fans 16 are welded and fixed on the vertical section of the steel containment vessel 3 and the inner wall of the dome, such as Image 6 with Figure 7 Shown, all the other are identical with embodiment 1. The number of heat exchange fans 16 ranges from 100 to 3000, depending on the condition of the containment, to enhance convective heat transfer in the containment, and can be arranged at all positions on the inner wall of the containment.

[0043] The heat exchanging fans 16 are low-power direct current electric fans for enhancing heat exchanging, and each power is 100W-300W. The heat exchanging fan 16 is activated in case of an accident, is controlled by the safety control system, and is powered by the emergency DC power bus 18 . The distance between the heat exchange fan 16 and the wall of the containment vessel 3 is 10cm-200cm (for example: 10mm, 100mm or 200mm). The distance between adjacent rows of heat exchange f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com