Light emitting diode crystal grain and light emitting diode packaging structure using same

A technology of light-emitting diodes and grains, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of uneven light output and weak light intensity of light-emitting diode grains 100, and achieve the effect of increasing the light output range and uniform light output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will be combined with Figure 3-12 The present invention is described in further detail.

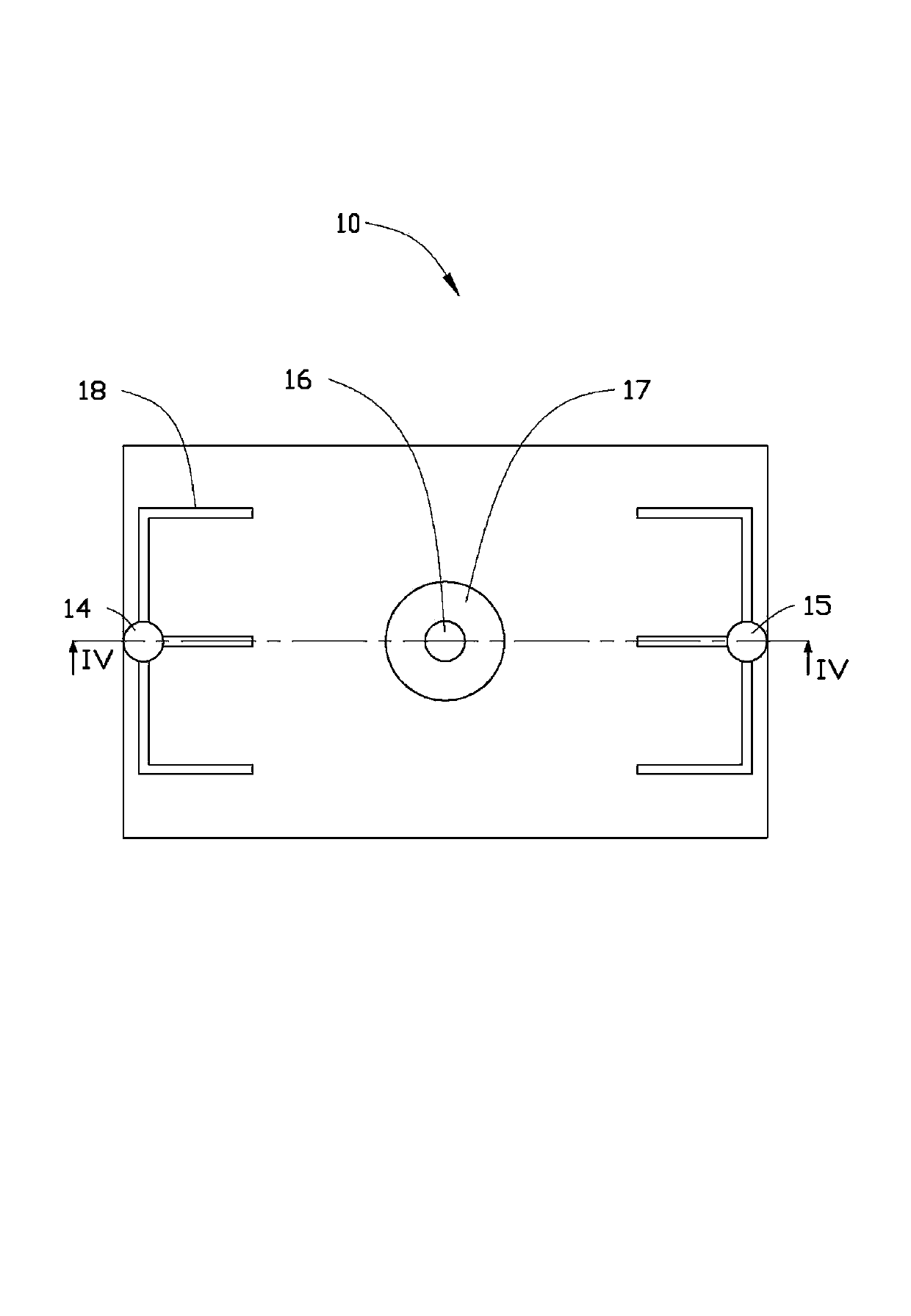

[0025] see Figure 4 The LED die 10 according to the first embodiment of the present invention includes a substrate 11 , an epitaxial layer 12 , a transparent conductive layer 13 , a first electrode 14 , a second electrode 15 and a common electrode 16 .

[0026] The material of the substrate 11 may be one of sapphire (Al2O3), silicon carbide (SiC), silicon (Si), gallium nitride (GaN) or zinc oxide (ZnO).

[0027] The epitaxial layer 12 includes a first semiconductor layer 121 , a second semiconductor layer 123 and an active layer 122 sandwiched between the first semiconductor layer 121 and the second semiconductor layer 123 . The first semiconductor layer 121 , the active layer 122 and the second semiconductor layer 123 are sequentially disposed on the substrate 11 . In this embodiment, the first semiconductor layer 121 and the second semiconductor layer 123 are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| light emitting angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com