Helix milling cutter with compound blade

A technology of helical milling cutters and milling cutters, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., and can solve the problems of loss, overall destructiveness, and cutting edge cutting resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

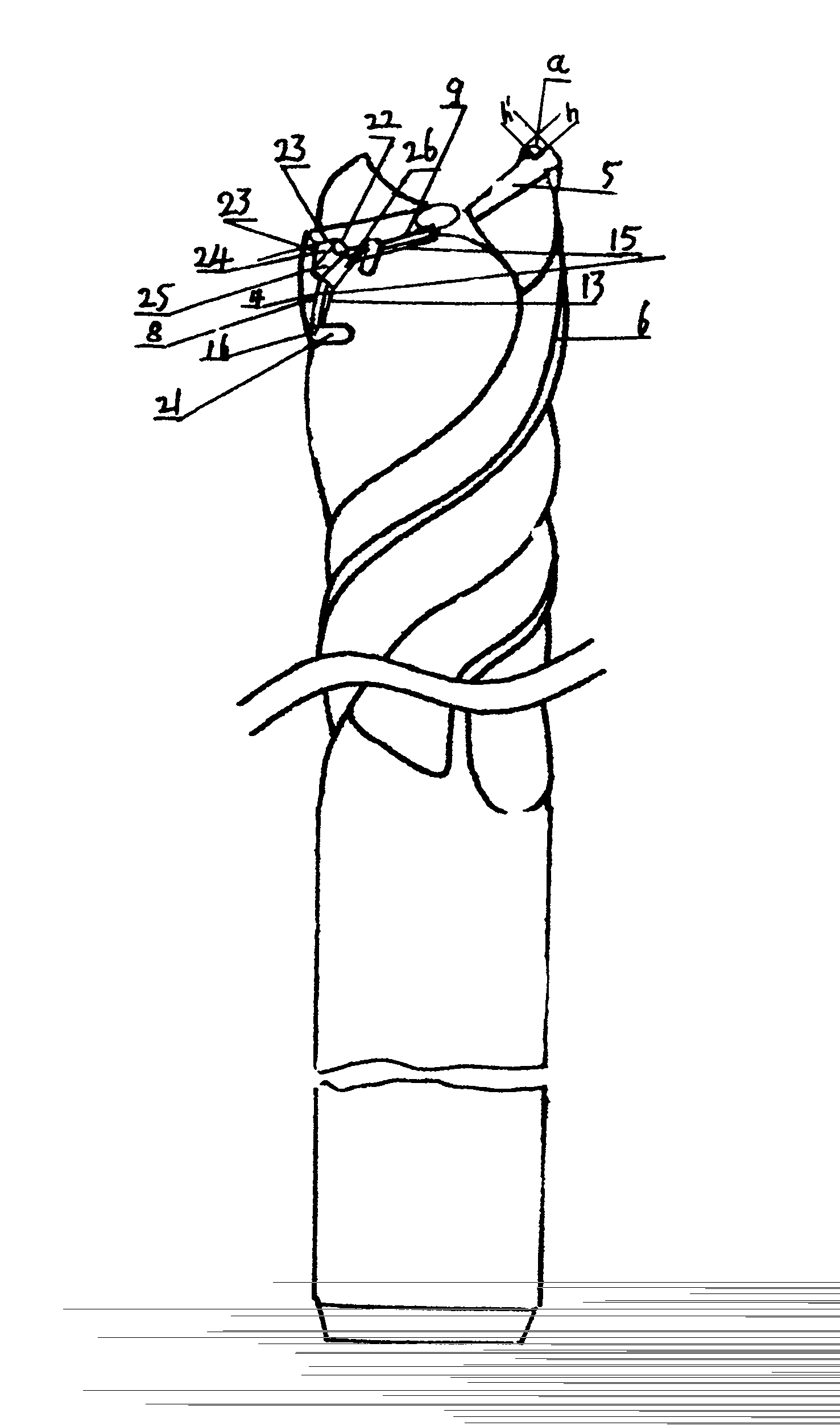

[0036] A compound spiral straight shank end mill such as figure 1 , figure 2 As shown, the composite helical straight shank end mill of the first embodiment of the present invention involves a variety of common straight shank end mills, straight shank end mills, beveled straight shank end mills, threaded shank end mills, etc. End mills with different shanks, a compound edge helical milling cutter, involving various ordinary straight shank end mills, or various cut straight shank end mills, or various beveled straight shank end mills, or various thread Shank end mills, or various tapered shank end mills, or various tapered tubular or straight tubular spiral edge milling cutters, or various tapered tubular, and various straight tubular spiral edge milling cutters are set at the front end Milling cutters with circular cutting edges, or combined edge milling cutters with annularly arranged cutting edges, or cylindrical helical edge milling cutters with shanks at both ends or one...

Embodiment approach 2

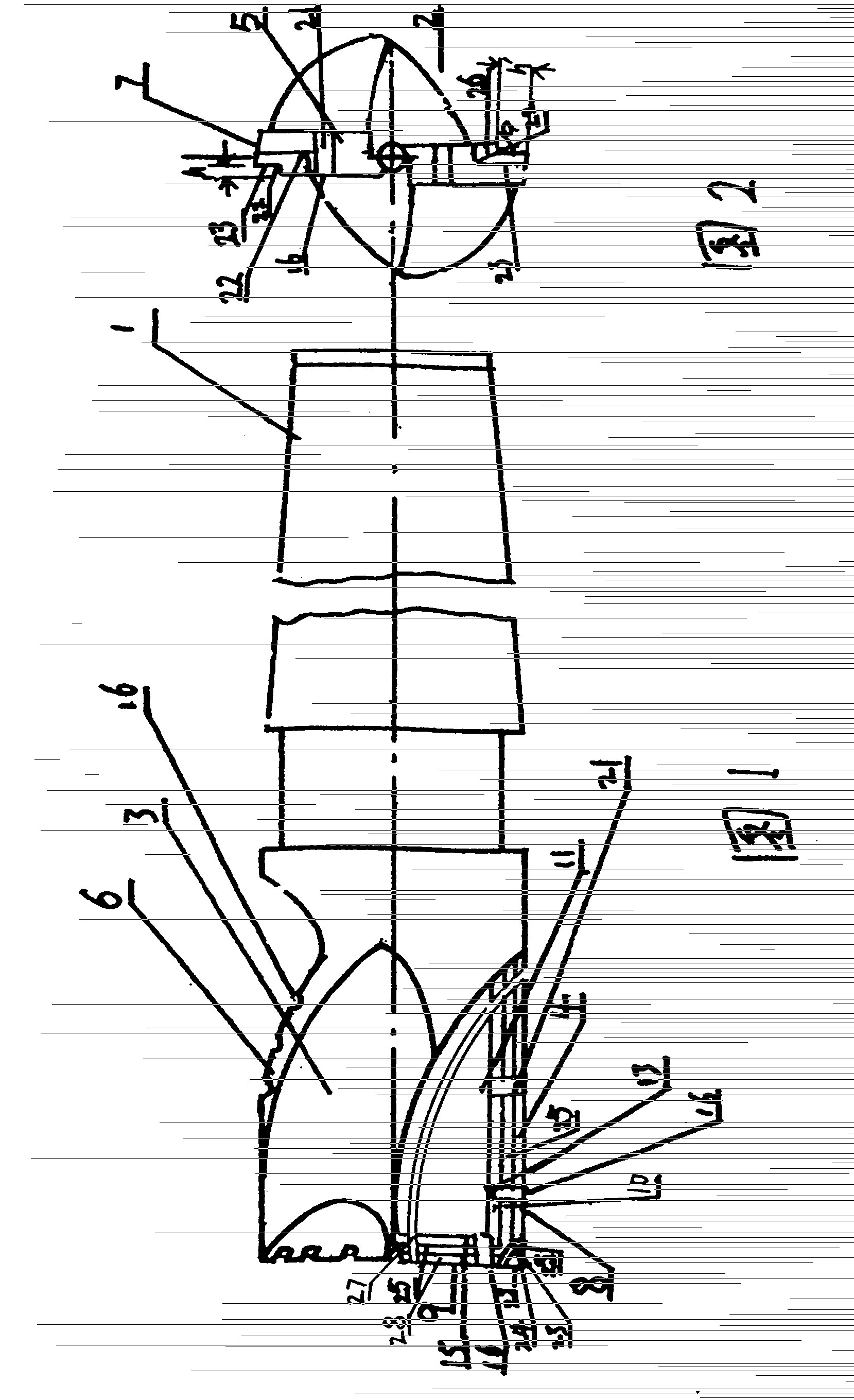

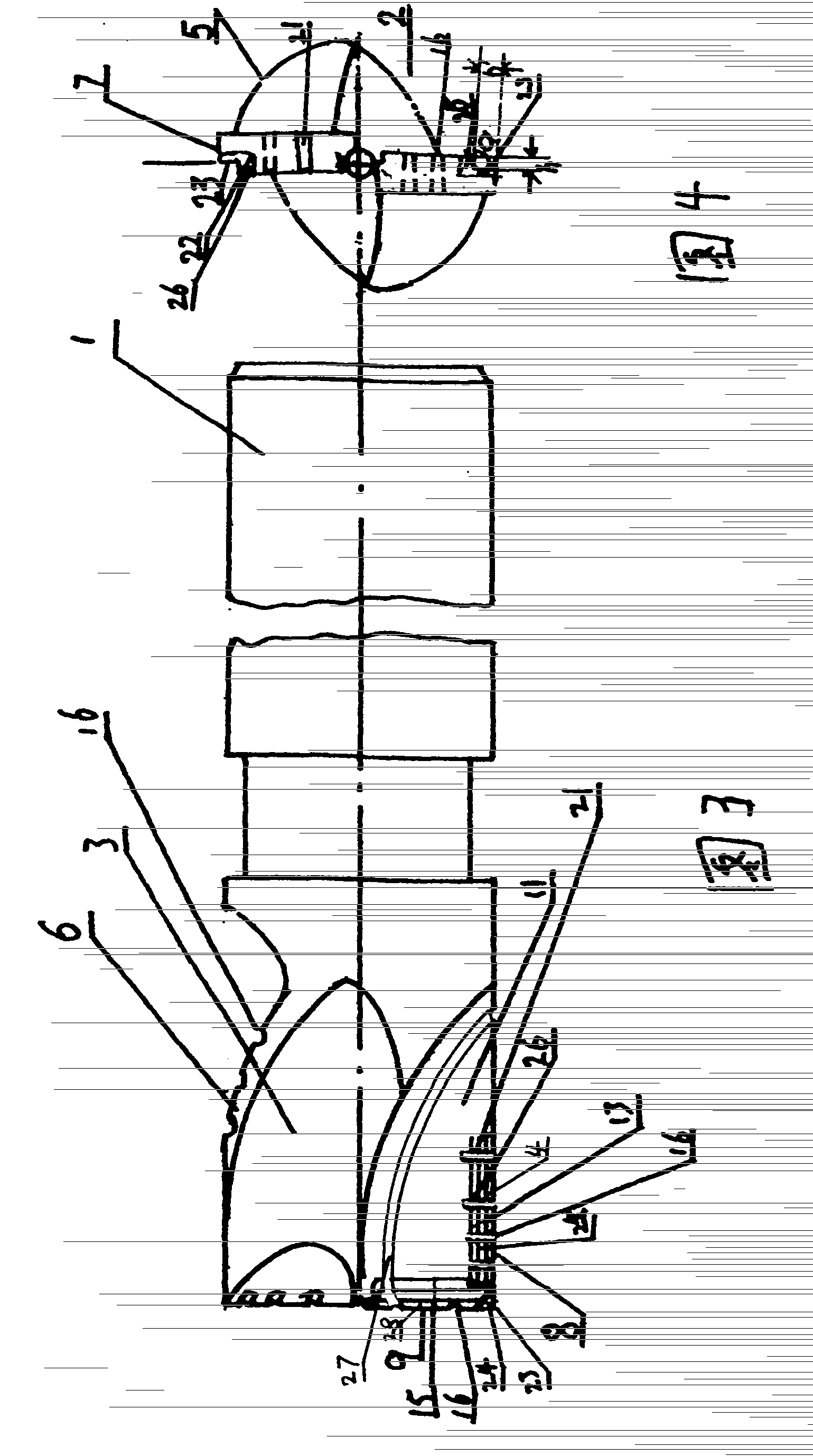

[0039] A compound spiral taper shank end mill such as image 3 , Figure 4 As shown, the compound spiral taper shank end mill of the second embodiment of the present invention, on the basis of the effect of the first embodiment, the present invention is provided on the stepped spiral cutting surfaces 4, 11 of the spiral cutting blade 3 At least one level of helical groove 27, on the cutting edge 9, or the helical cutting edge 8, or on the side cutting edge, or on the front cutting edge, arc-shaped protrusions or oblique protrusions 25 are provided with at least one step, or compound Cutting edge 15, or composite helical cutting edge 13, or composite side cutting edge, or composite front cutting edge, and be formed with at least one step, or step edge, or cutting edge; , or cutting body, or helical cutting blade, or helical cutting body, at least one cutting edge, or compound cutting edge, or helical cutting edge, or compound helical cutting edge, or side cutting, or compound ...

Embodiment approach 3

[0042] A cemented carbide composite helical tooth straight shank end mill such as Figure 5 , Image 6As shown, the cemented carbide composite helical straight shank end mill of the third embodiment of the present invention, on the basis of the effects of the first and second embodiments, the present invention has a helix on each helical cutting blade 3 Cutting surface or cutting surface, on the rear side or back side of the helical cutting surface or cutting surface facing the cutting direction, there are rear cutting surface 5 and helical secondary cutting surface 6, helical cutting surface or cutting surface and rear cutting surface 5, or helical secondary The cutting surfaces 6 intersect to form at least one helical cutting edge, or at least one cutting edge, towards the inner side of the helical cutting surface or the cutting surface in the helical cutting direction, the inner side of the arc-shaped protrusion or oblique protrusion 25, at least one Stepped composite spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com