Preparation of graphene oxide and post-processing method for waste liquor

A graphene and graphene technology, which is applied in the fields of graphene oxide preparation and waste liquid post-treatment, can solve the problems of doubling sulfuric acid and potassium permanganate, and achieve the effects of avoiding emissions, fast preparation methods, and simplified waste liquid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following examples. The methods are conventional methods unless otherwise specified. The raw materials can be obtained from public commercial sources unless otherwise specified.

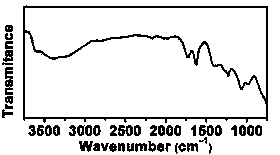

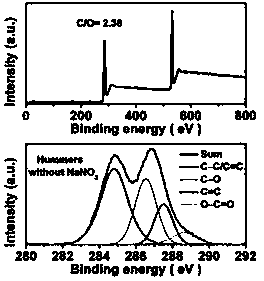

[0027] The preparation method of the present invention improves the Hummers method without adding sodium nitrate at all. The specific implementation steps are: mix 3.0 g of natural graphite powder (325 mesh) with 70 mL of 98wt% concentrated sulfuric acid in an ice-water bath, and slowly add 9.0 g of potassium permanganate after stirring evenly. The entire adding speed is controlled at about 20 minutes, and then Stirring was continued for 10 minutes, and the reaction mixture was stirred and reacted at 40° C. for 30 minutes. 140 mL of deionized water was added to the reaction solution, and after the temperature was raised to 95° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com