A method of purifying organic solution obtained from cyclohexanone oxime synthesis area

A technology of oxime synthesis zone and organic matter, applied in the direction of organic chemistry, oxime preparation, etc., can solve the problem of no public cleaning method and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

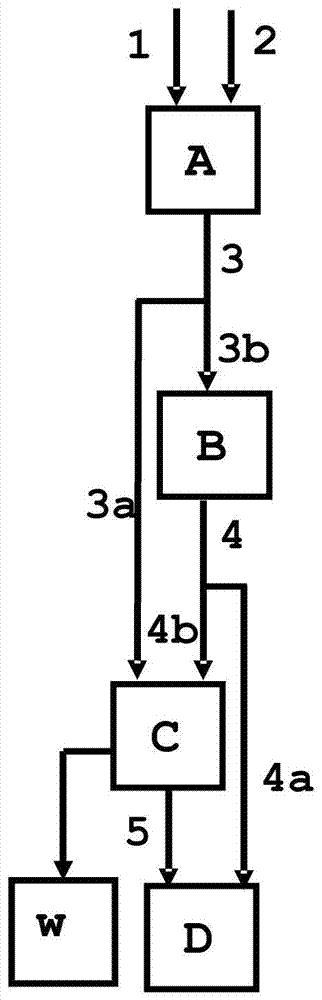

[0026] Preferably, in oxime synthesis zone [A], an aqueous reaction medium containing hydroxylammonium, phosphate and nitrate is contacted with ketone dissolved in a solvent.

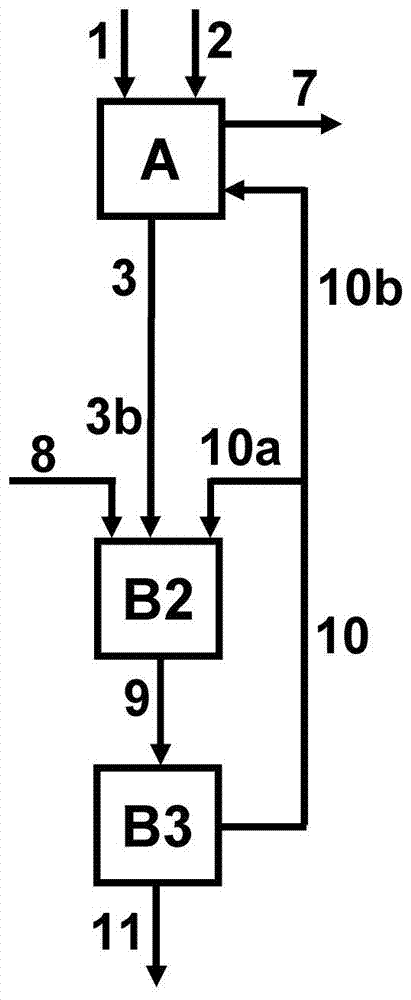

[0027] Preferably, before adding the organic solution to the cleaning zone [C], the organic solution is introduced into the cleaning zone [B], which comprises:

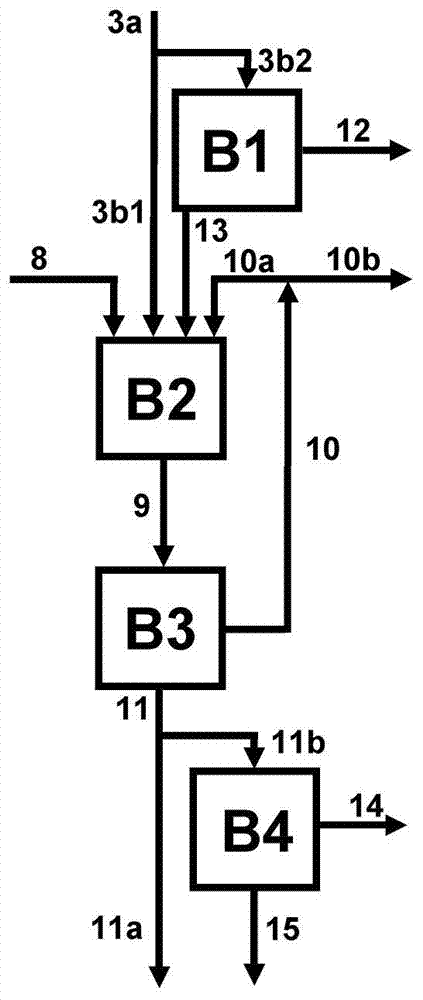

[0028] (1) In the liquid-liquid mixing zone [B2], the organic matter solution is mixed with water and / or aqueous solution, and the resulting mixture is input into the liquid-liquid separator [B3]. Optionally, after being added to the liquid-liquid Before the liquid mixing zone [B2], part of the aqueous medium contained in the organic solution is separated in the liquid-liquid separator [B1];

[0029] (2) Separate the resulting aqueous layer and the resulting organic layer in the liquid-liquid separator [B3] and discharge the organic layer from the cleaning zone [B], optionally, before the organic layer flows out, from the liquid-liquid Part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com