High-frequency quenching tool for gusset plates of gear shifting connecting rod of automobile transmission and working method thereof

An automobile gearbox and high-frequency quenching technology, which is applied in the improvement of process efficiency, manufacturing tools, and energy efficiency, can solve the problems of slow high-frequency quenching, inability to spray water to cool down, and poor quenching effect. Short interval, good quenching effect, timely spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

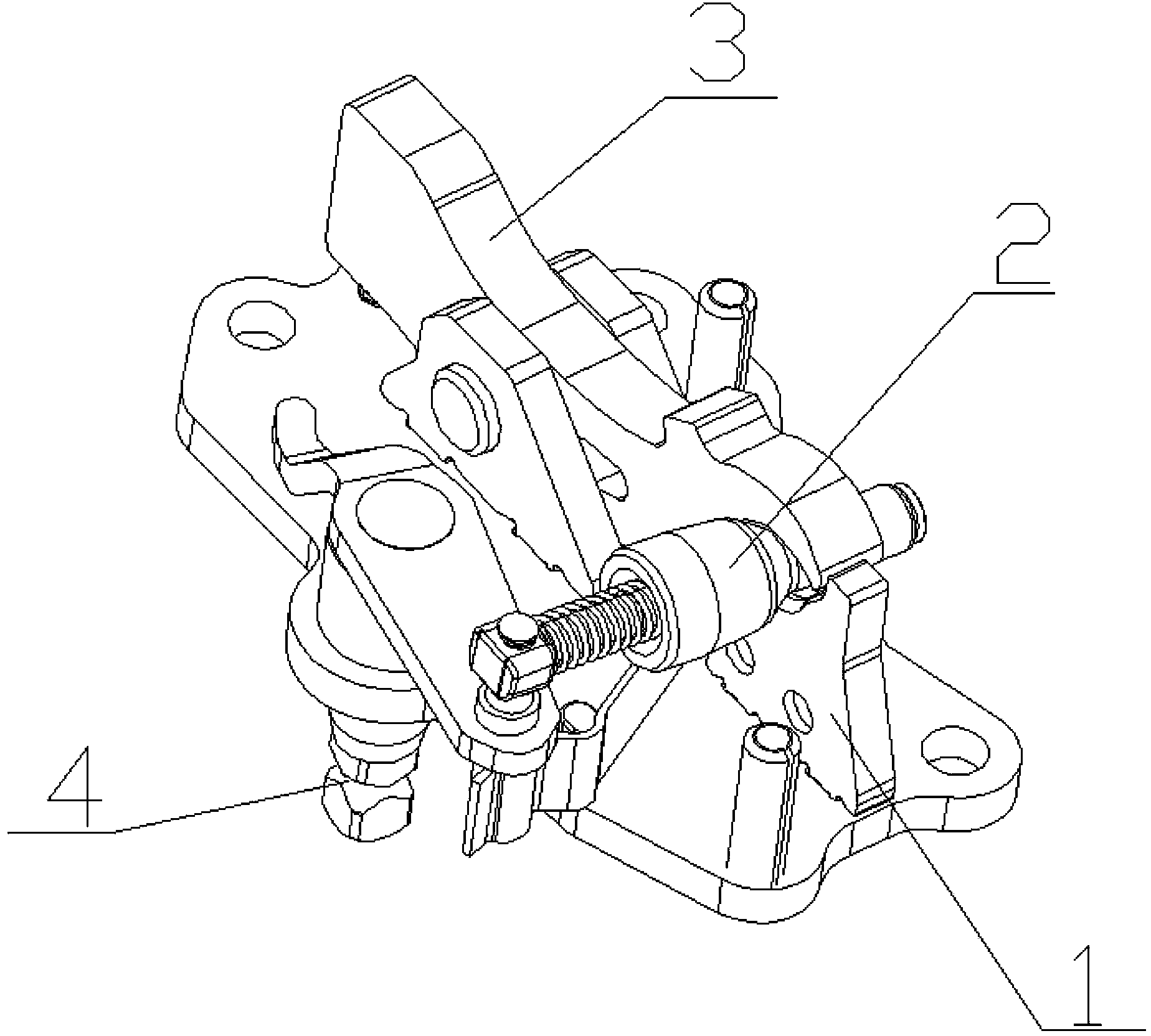

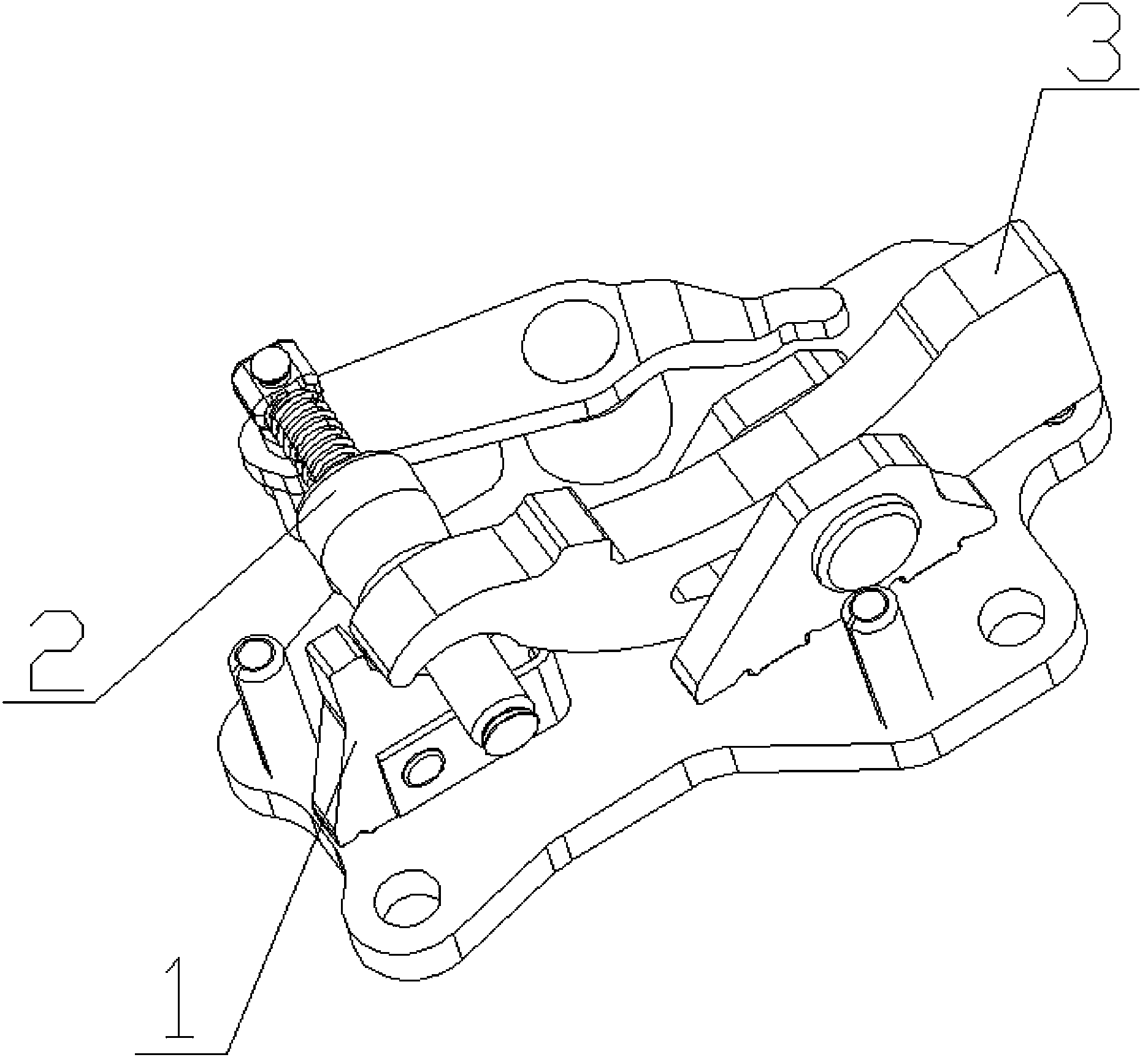

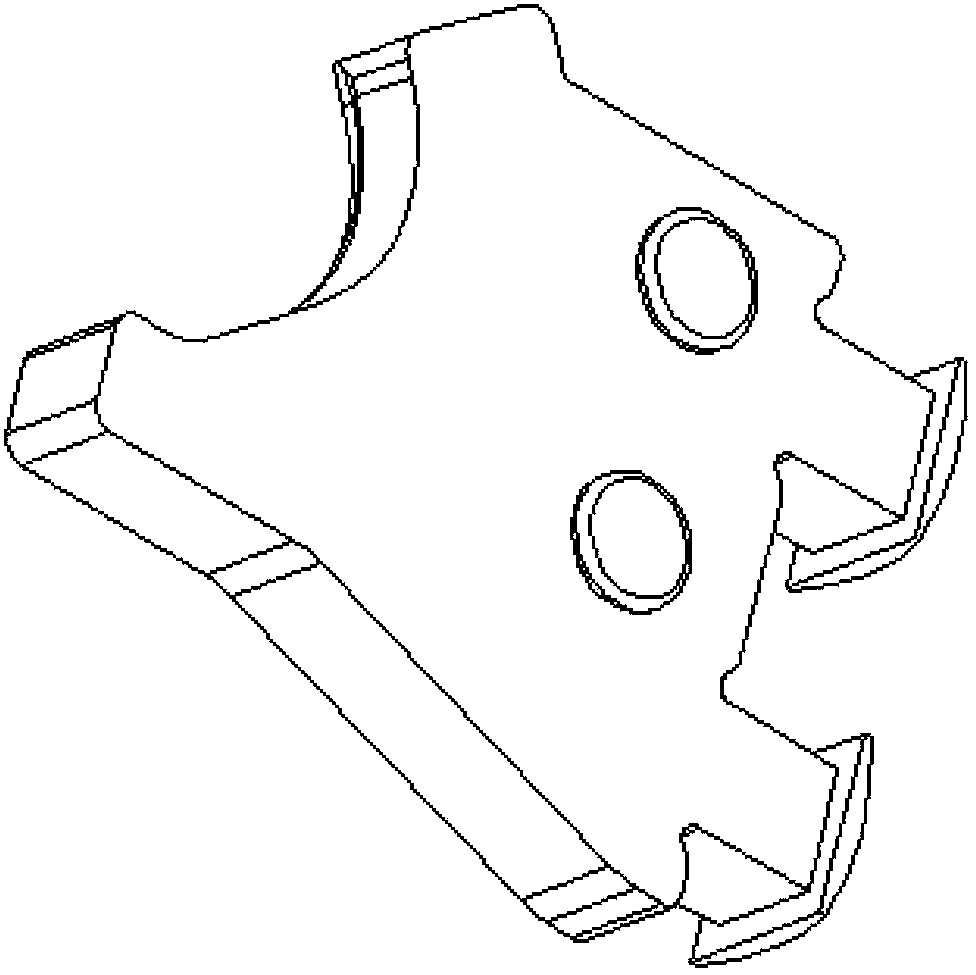

[0032] see Figure 7-12 , a kind of high-frequency quenching tooling for the shifting connecting rod gusset of an automobile gearbox, comprising a gusset clamp 5 and a high-frequency quenching inductor 6; the gusset clamp 5 has a support plane, and the middle part of the support plane It has a downwardly recessed arc-shaped groove 502, and a pair of protrusions 501 are arranged on the support plane, and the protrusions 501 are inserted into the slots on the gusset plate 1, and the two gusset plates are fixed on the support plane, Their respective arc-shaped working faces are facing inward, and are arranged symmetrically inside the arc-shaped groove 502; the high-frequency quenching inductor 6 is fixed on the high-frequency quenching equipment, and can move up and down with the equipment, including the upper end Water injection pipe 601, the water injection pipe 601 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com