High-sensitivity fiber Bragg grating strain sensor

A technology of strain sensor and optical fiber grating, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problem of low sensitivity of strain measurement and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

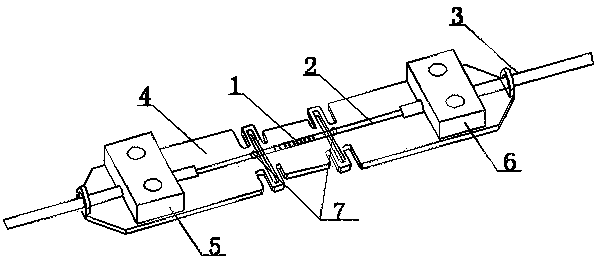

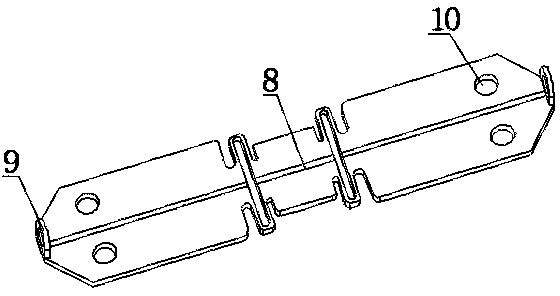

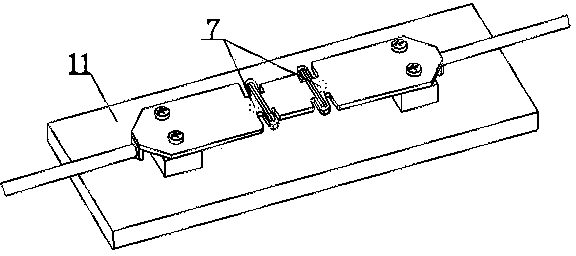

[0021] Such as figure 1 with figure 2 As shown, the manufacturing process of the high-sensitivity optical fiber strain sensor is as follows: the fiber grating (1) terminated with the pigtail is passed through the round holes (9) at both ends of the metal sheet structure (4), and the fiber grating (1) terminated with the pigtail is flattened. Lay it in the center of the metal sheet structure (4) and in the semicircular thin groove (8), so as to ensure that the optical fiber grating (1) to which the pigtail is terminated is in the center of the metal sheet structure (4). Point the adhesive (7) at one end of the optical fiber grating (1) that is terminated with the pigtail and outside the return hole on the side of the metal sheet structure. After the adhesive (7) is cured, the optical fiber grating (1) that is terminated with the pigtail ) is fixed, and a certain pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com