Intelligent load resistance box

A load resistance box, intelligent technology, applied in the direction of motor generator testing, etc., can solve the problems of time-consuming data, high cost, tedious manual operation, etc., and achieve the effect of saving time, reducing risks, and efficient detection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

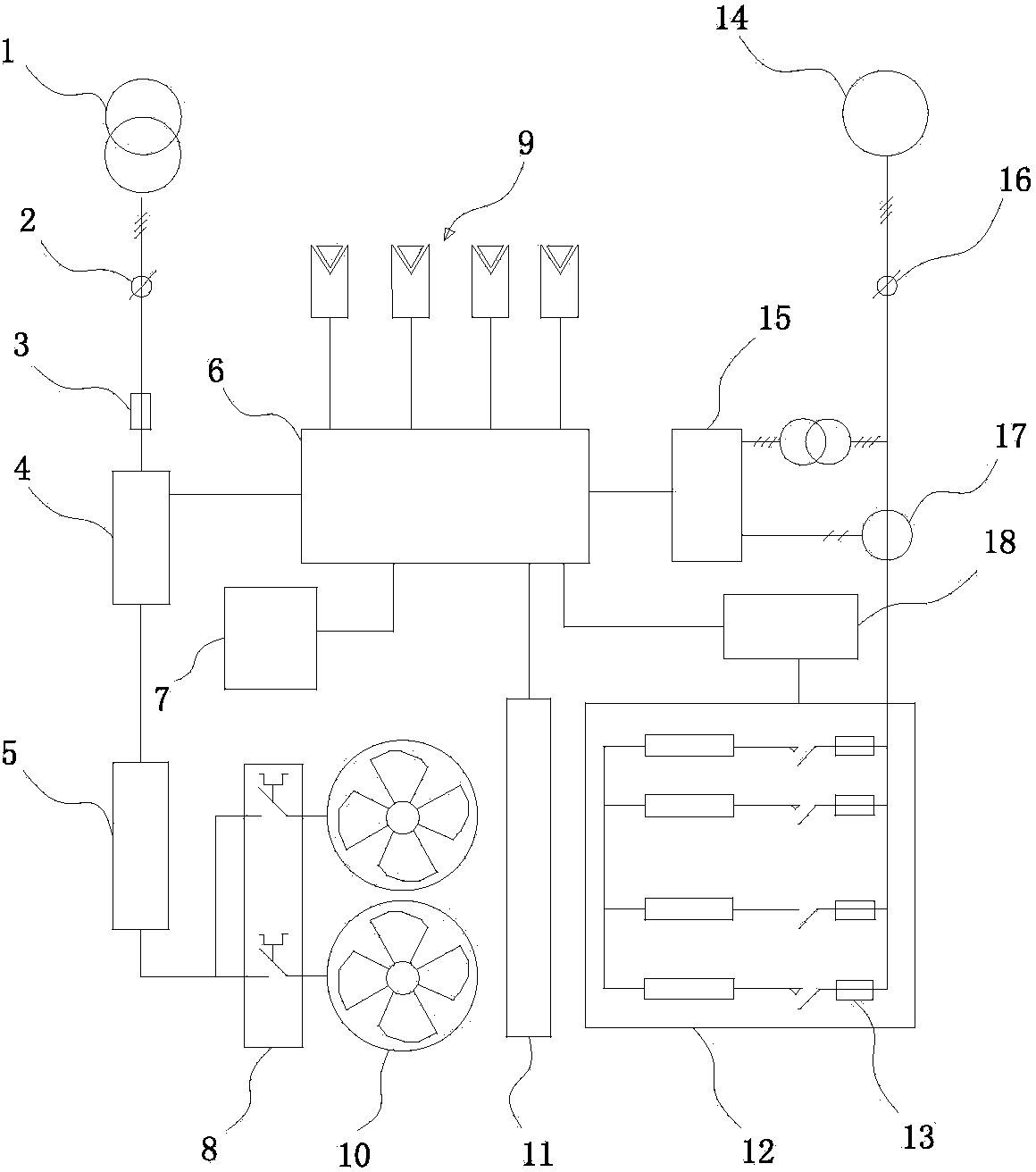

[0015] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 As shown, a kind of intelligent load resistance box of the present invention, it comprises AC load intelligent control system module 6, and the dry type load resistance module electrically connected with AC load intelligent control system module 6, automatic measurement and control module and input and output Module 9; the automatic measurement and control module includes a fuse 3, a temperature sensor 11, a current and voltage transformer 17, a thermal protection relay array 8 and an intermediate control relay array 18; the mains 1 is connected to one end of the fuse 3 through the terminal 2, and the fuse 3 The other end is connected to the input end of the working power distribution controller 4, the output end of the working power distribution controller 4 is respectively connected to the phase sequence automatic switcher 5 and the AC load intelligent control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com