Image direct output device

An output device, direct technology, applied in projection device, installation, optics, etc., can solve the problems of light source penetration attenuation, weight increase, complex structure of components, etc., to achieve the effect of continuous beam resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

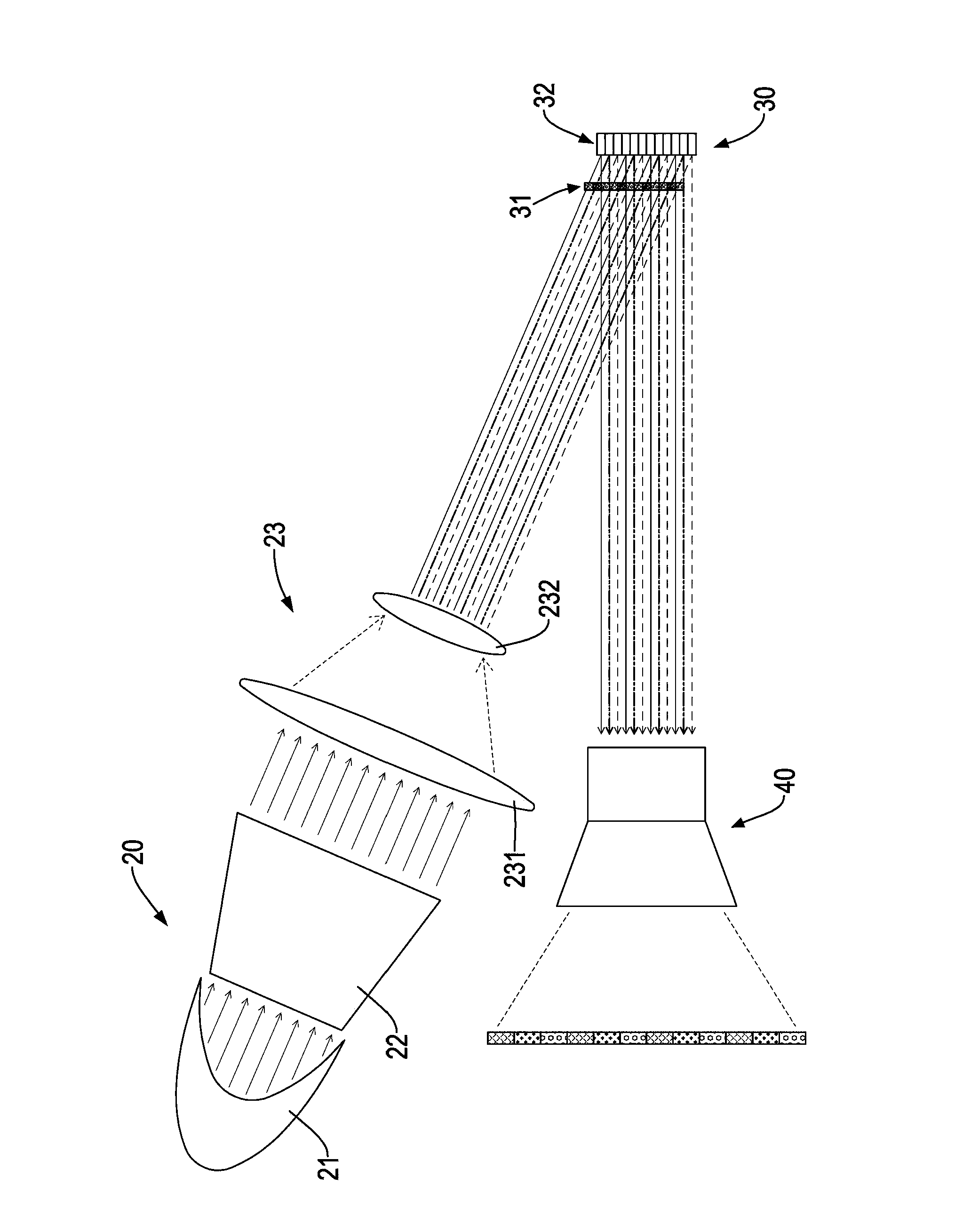

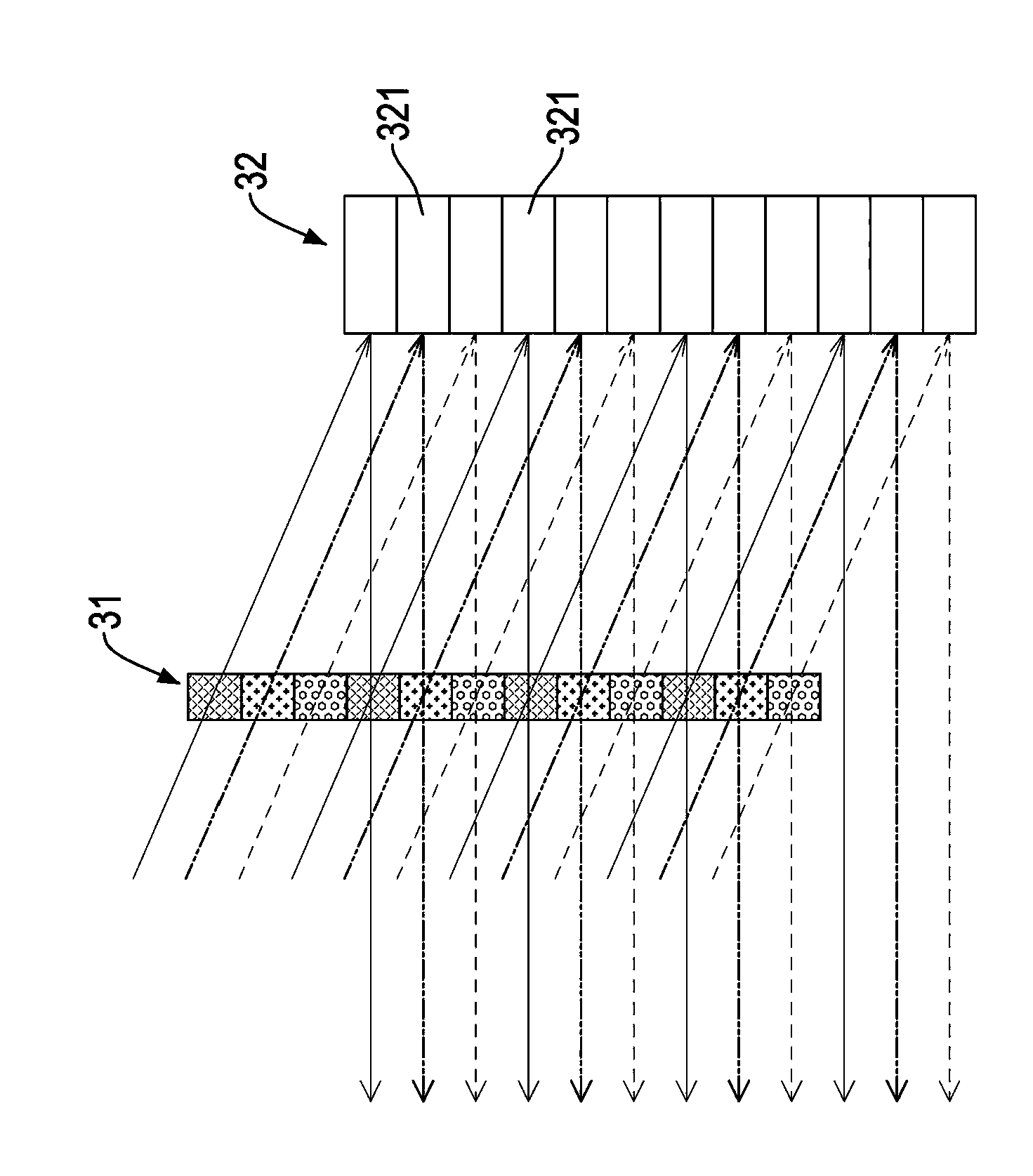

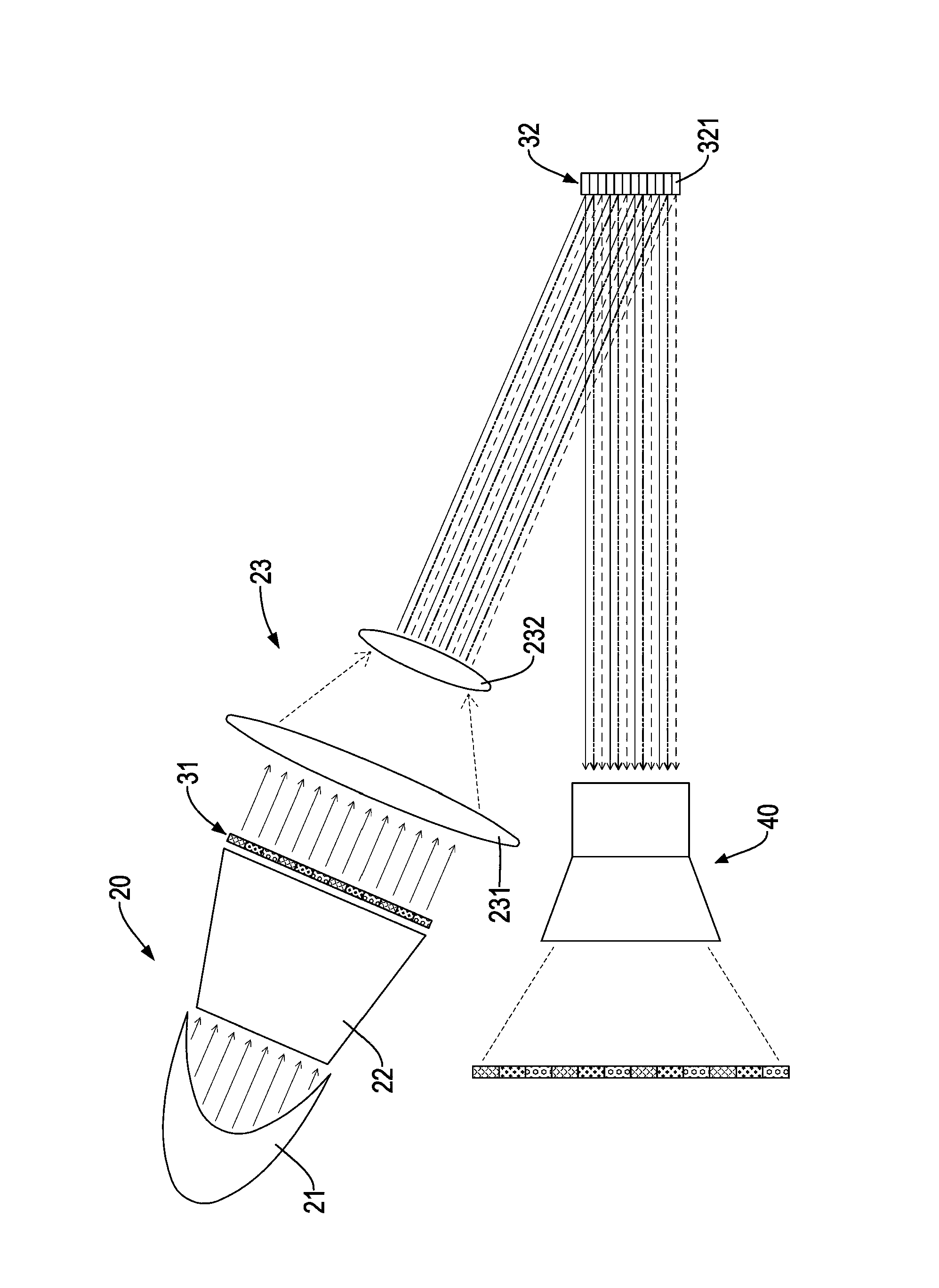

[0024] like figure 1 and image 3 As shown, the present invention relates to a direct image output device, including a housing (not shown), a light source group 20 accommodated in the housing, a digital microcomputer set in the housing and used to receive the light source group 20 A chip device 30 (Digital Micro-mirror Device, DMD for short) and a projection lens 40 (Projection Lens) arranged in the housing for outputting light source, wherein:

[0025] The light source group 20 is provided with a light source 21, a light guide column 22 and a miniature lens group 23, the light guide column 22 is used to receive the light source 21, so as to guide the divergent light source 21 into a parallel output light source 21, and the The microlens 23 is used to receive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com