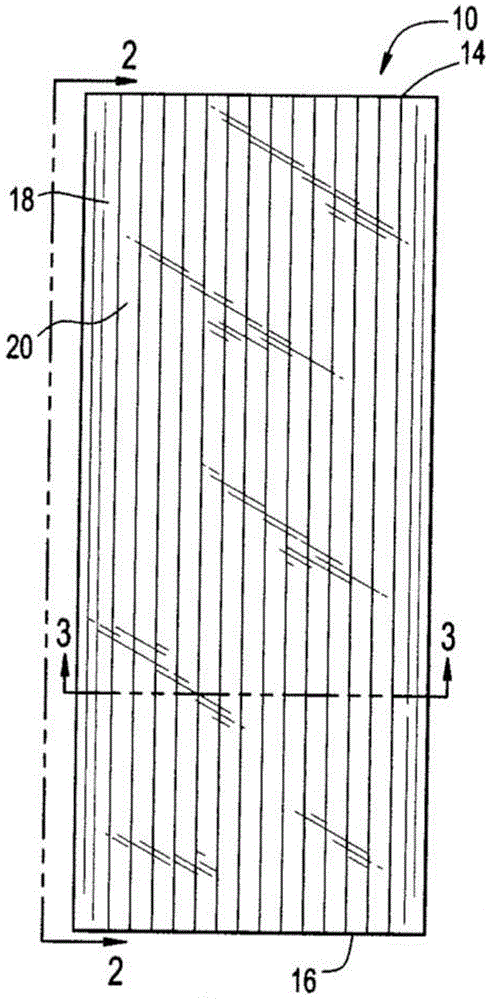

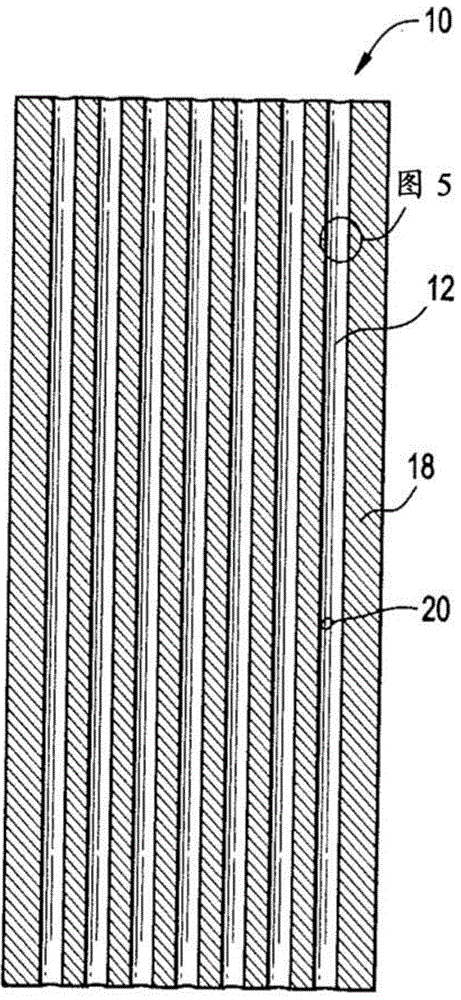

Reinforced microcapillary membranes and foams

A technology of microcapillary and foam, applied in the direction of transportation and packaging, microstructure technology, microstructure devices, etc., can solve problems such as failure to meet mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

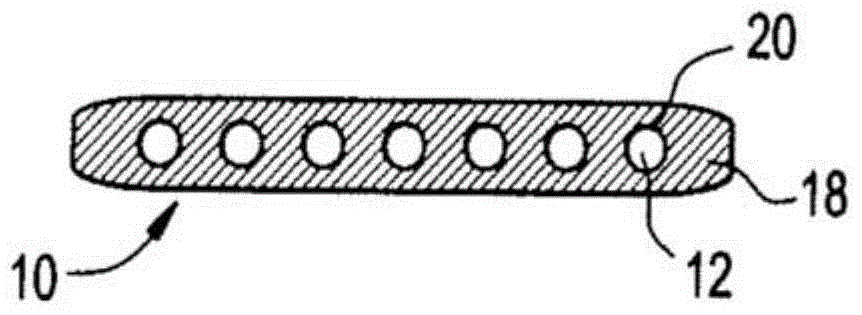

[0092] The reinforced film 1 of the present invention was prepared according to the following procedure.

[0093] Matrix materials include linear low density polyethylene (LLDPE), which is known by the trade name DOWLEX TM NG5056G is available from The Dow Chemical Company and has a density of about 0.919 g / cm according to ASTM-D792 3 , and a melt index (I 2 ) is about 1.1 g / 10 minutes. The second thermoplastic material placed in the microcapillary is homopolymer polypropylene (hPP), which is sold under the trade name DOW TM Polypropylene H502-25RG was purchased from The Dow Chemical Company and had a density of 0.900 g / cm according to ISO1183 3 and a melt mass flow rate of 25 g / 10 min measured according to ISO 1133 at 230°C and 2.16 kg.

[0094] Both the primary and secondary extruders are single screw extruders. The main extruder was a Betol 1820J with a screw diameter of about 20 mm connected to a gear pump, thus providing a non-pulsating polymer flow. Downstream of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com