Jigsaw automatic welding machine and unit

An automatic welding machine and piecing technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity, low production efficiency, hidden dangers of workers, etc., to eliminate hidden dangers and improve safety. The effect of production efficiency and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

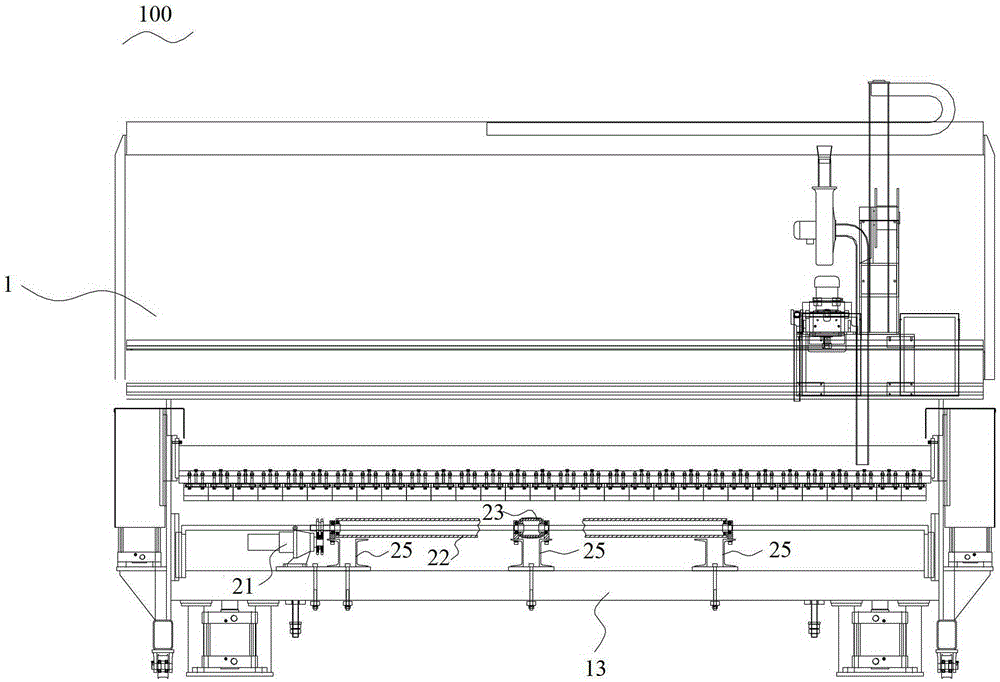

[0018] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

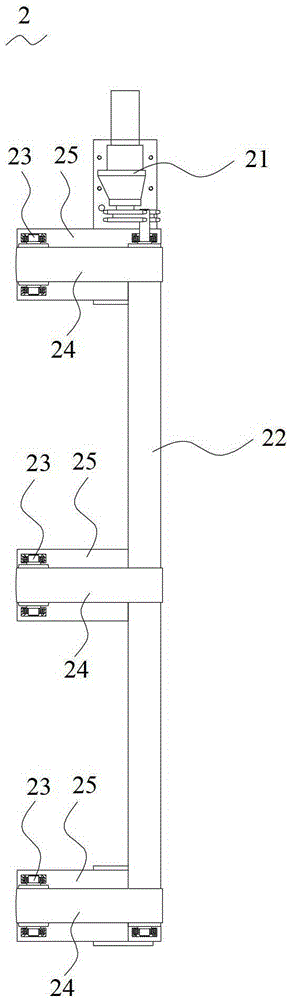

[0019] refer to figure 1 , the plate power transmission mechanism 2 of the present invention is applied to an automatic panel welding machine, and the plate power transmission mechanism 2 includes: a motor reducer 21 , a driving wheel 22 and three driven wheels 23 .

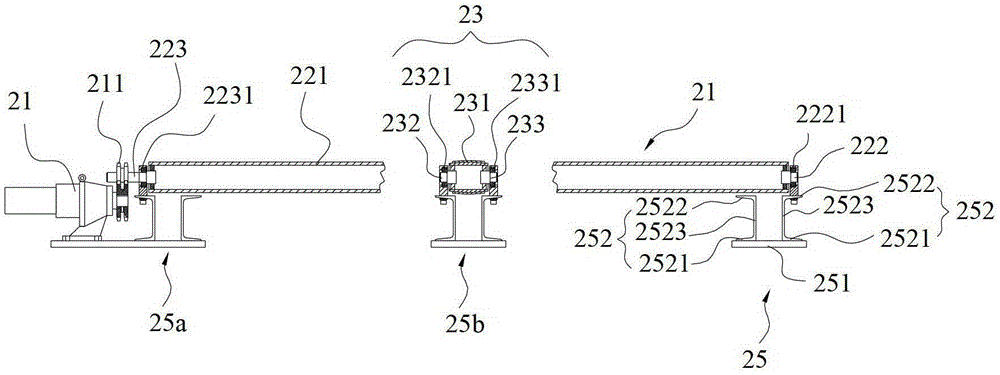

[0020] combined reference figure 2 The driving wheel 22 comprises: a cylindrical driving roller 221 and two driving shafts 222, 223 respectively fixed at both ends of the driving roller, and each driving shaft 222, 223 is connected to the axial center of the driving roller 221. Each driven wheel 23 is located at one side of the length direction of the driving wheel 22 and is distributed at intervals along the length direction of the driving wheel 22, wherein two driven wheels 23 are close to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com